Method and machine for pre-processing of molding material, injection molding machine and injection molding method

A technology of pretreatment device and molding material, applied in coating and other directions, can solve the problem of yellowing of resin products, and achieve the effects of temperature stability, temperature rise inhibition, and oxidation inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

[0059]

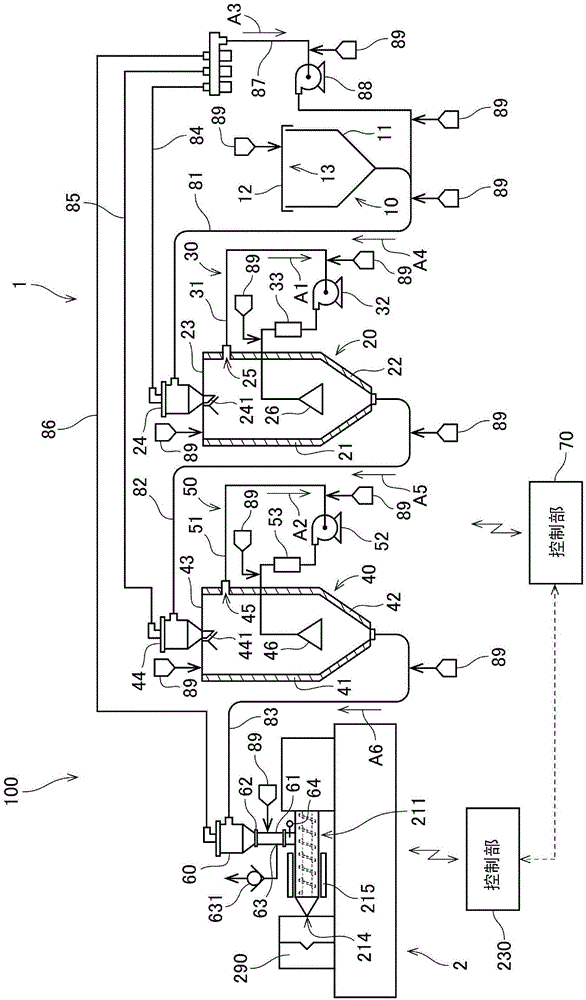

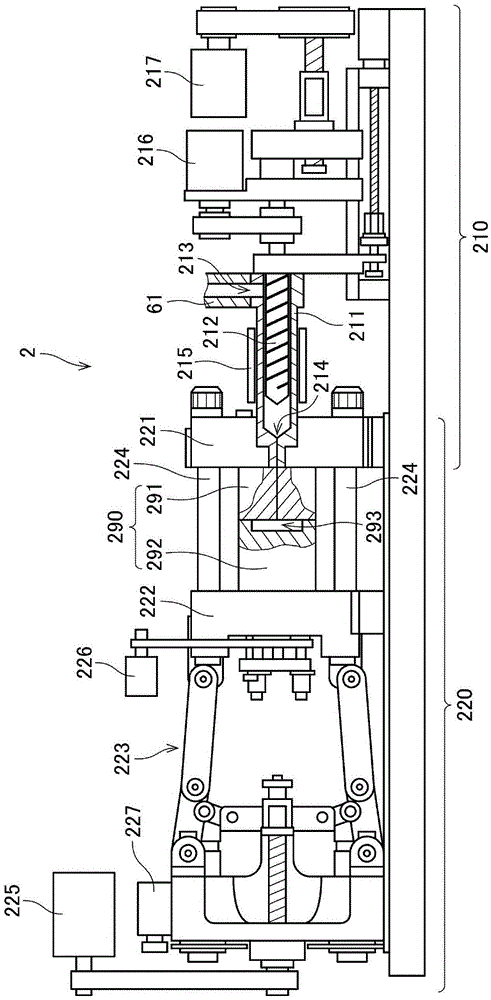

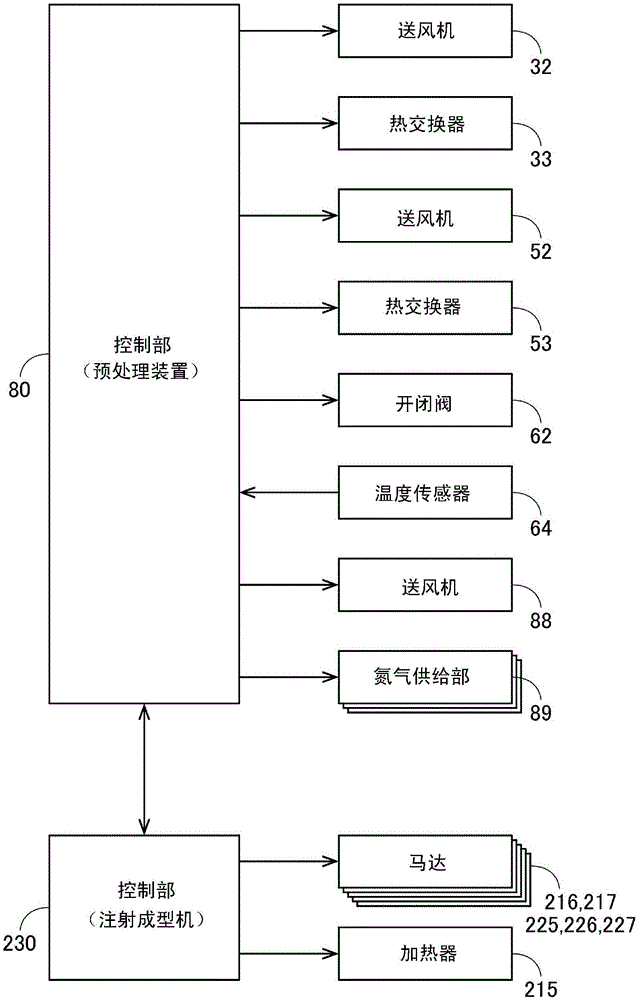

[0060] figure 1 It is a figure which shows the structure of the preprocessing apparatus 1 and the injection molding machine 2 concerning one embodiment of this invention. The preprocessing device 1 performs preprocessing such as drying on resin pellets, which are molding materials made of powder or granular materials, and supplies the processed resin pellets to the injection molding machine 2 . The injection molding machine 2 melts the resin pellets supplied from the preprocessing device 1 and injects them into the mold 209 to solidify the resin in the mold 209 to form a resin product. In addition, in figure 1 In , the structure of the injection molding machine 2 is simplified. Pretreatment device 1 and injection molding machine 2 such as figure 1 shown are connected to constitute a single resin product manufacturing system 100 .

[0061] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com