Hot pressing injection mold and processing technology for integrally molding fibrilia plate and surface layer

A technology of injection mold and processing technology, applied in the direction of coating, etc., can solve the problems of unfavorable product processing and use, excessive emission performance of parts, large investment in molds, etc., and achieve the effect of improving rigidity and strength, reducing usage, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

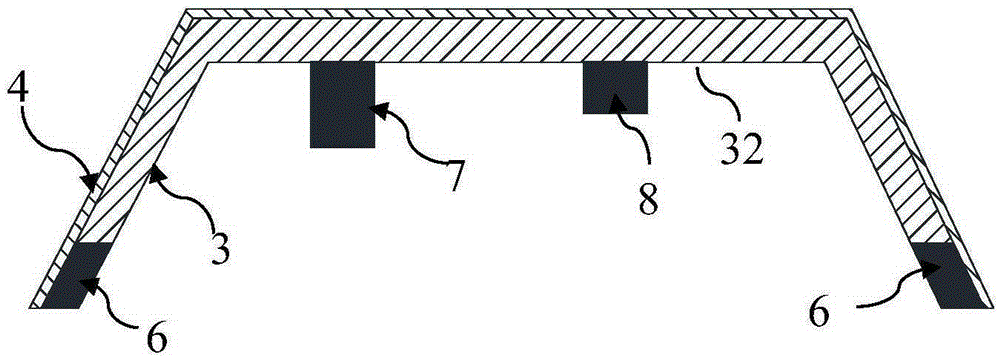

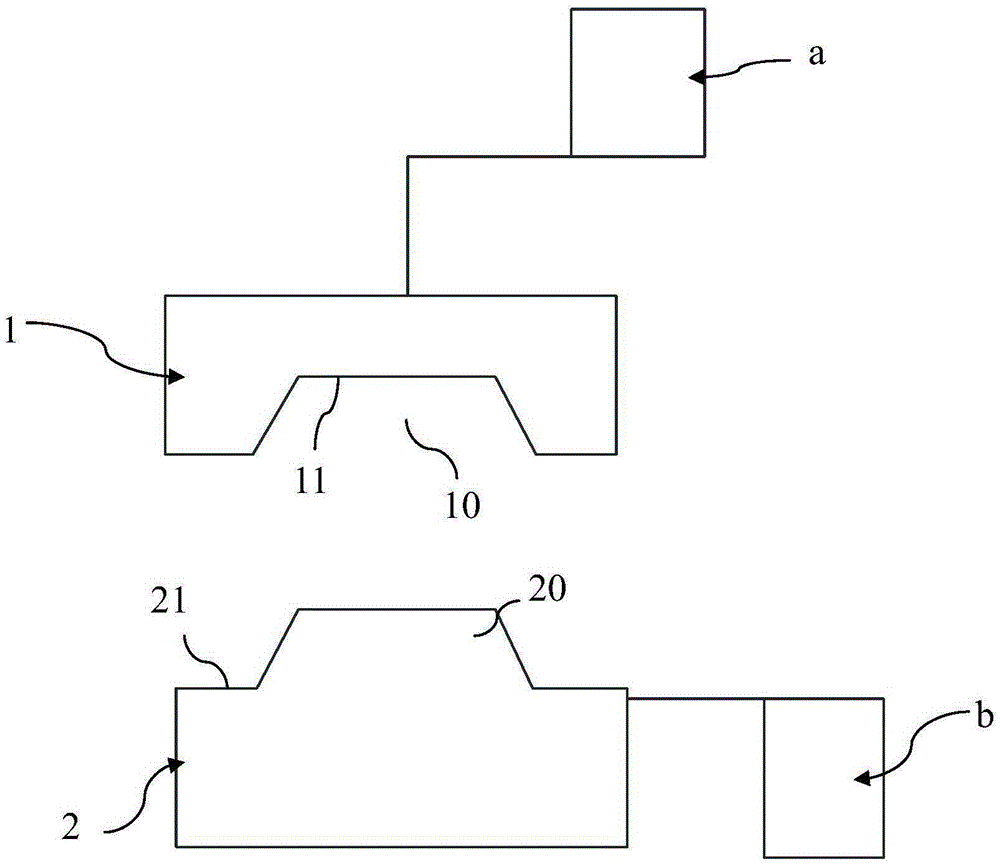

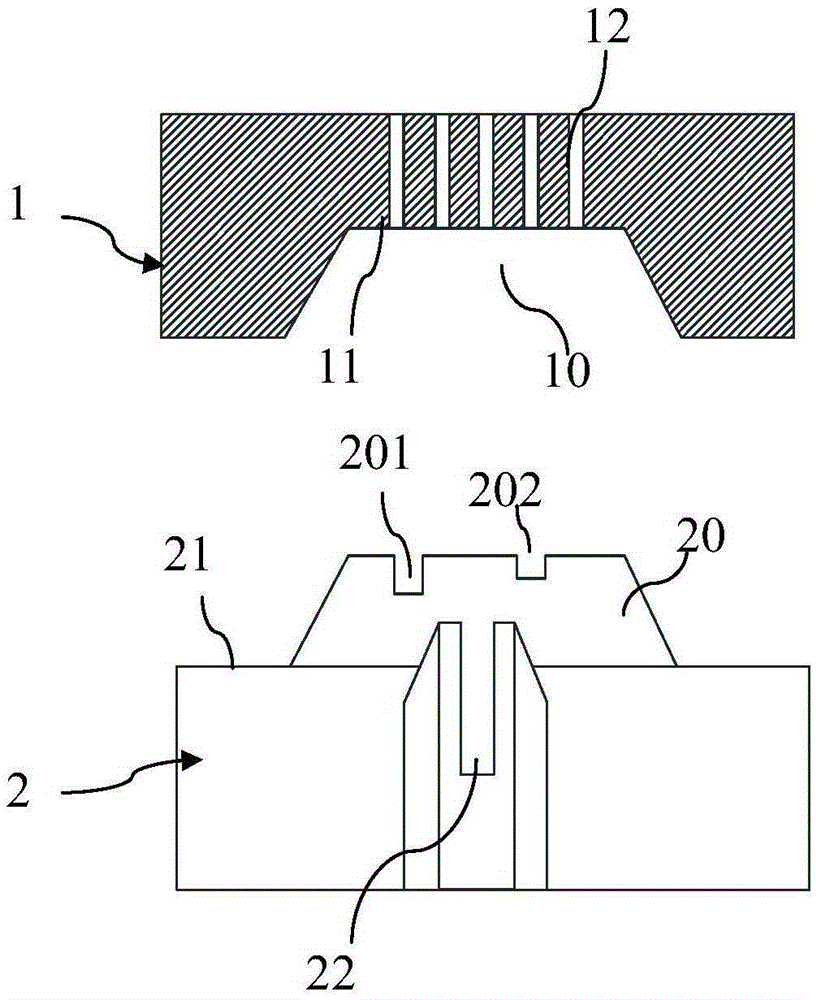

[0043] Such as Figure 1-8 As shown, an embodiment of the present invention provides a hot-press injection mold for integral hot-press injection molding of the hemp fiber board 3 and the skin layer 4 thereon, including a lower mold 2, an upper mold 1 and a vacuum pump a.

[0044] The upper mold 1 is movably arranged on the lower mold 2, and has a cavity 10 in the upper mold 1, the lower mold 2 is provided with a core 20 matching the cavity 10, and a sealing ring is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com