Automatic package inspection line for ceramic tiles

An automatic inspection and ceramic tile technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of difficult production control, no automatic production line, high labor intensity of workers, etc., to reduce the difficulty and labor intensity, improve the level of automation, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

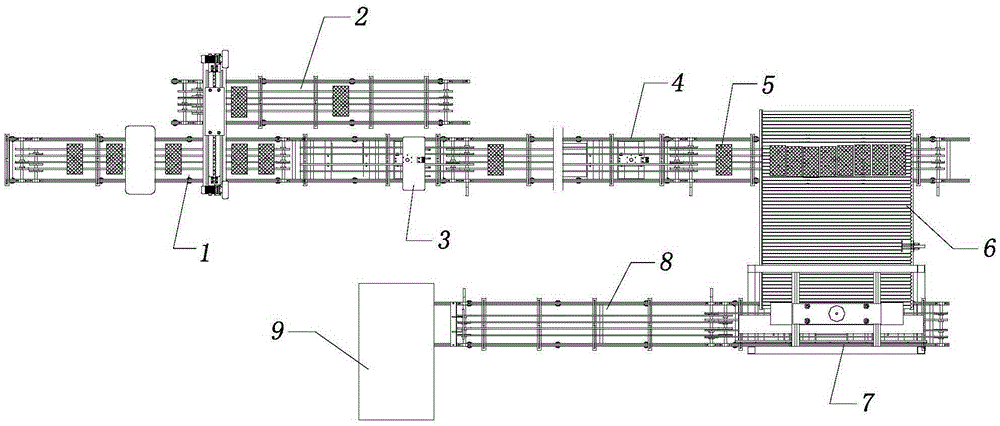

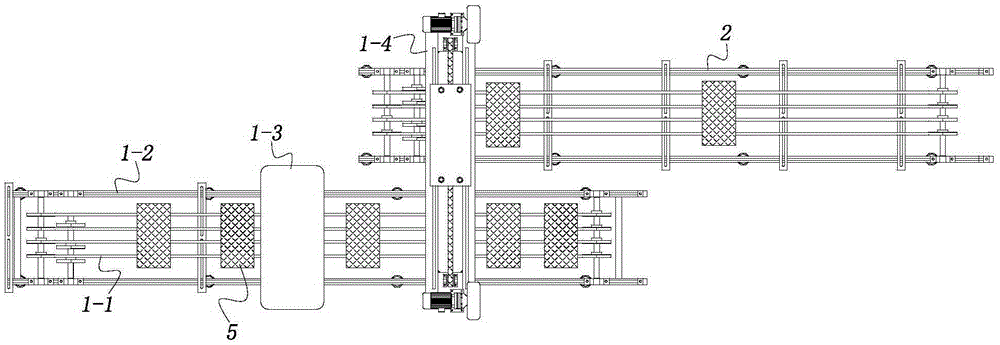

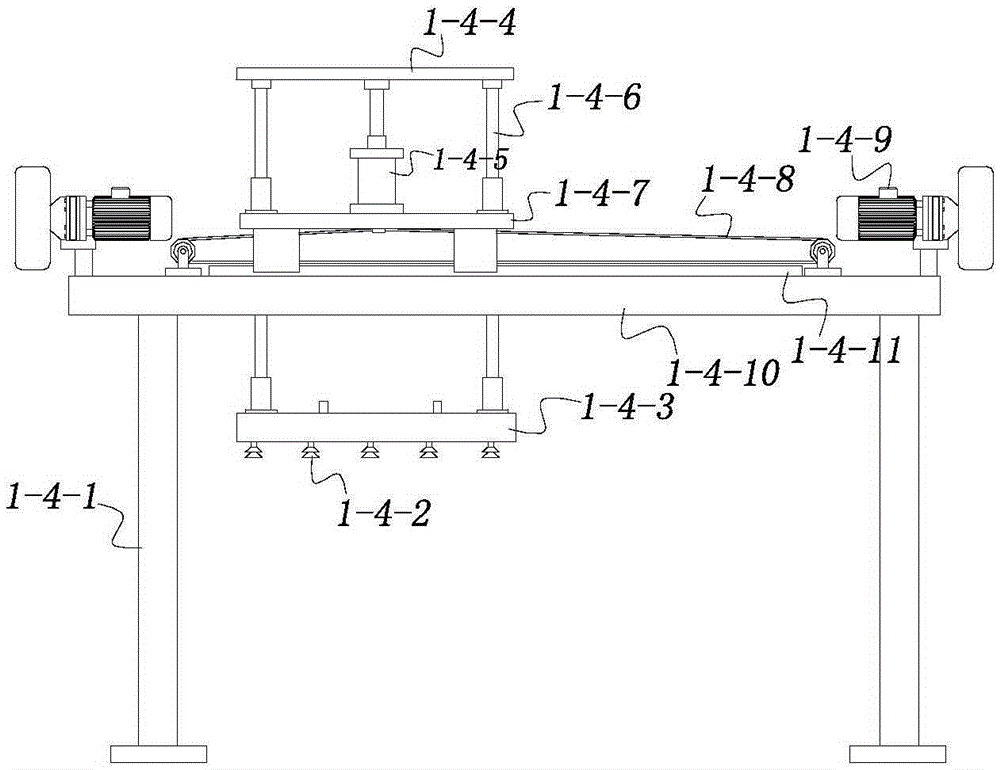

[0025] See figure 1 , the present invention includes sequentially according to the flow direction of tiles 5: an inspection device 1 for detecting defective products; a glue spraying device 3 for spraying an anti-scratch adhesive layer on the surface of tiles 5; The feeding platform 6 for sorting and conveying; the feeding line 4 located at the head end of the feeding platform 6 and docked with the glue spraying device 3; the stacking device 7 located at the tail end of the feeding platform 6 and stacking the sequence of tiles 5 according to preset rules; The first end is docked with the stacking device 7, and the sending line 8 is used to send out the stacked tiles 5.

[0026] A receiving line 2 for receiving and transferring defective products is also provided on the side of the inspection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com