Fluidized bed gas collecting hood

A technology of gas collecting hood and fluidized bed, which is applied in the field of gas collecting hood, can solve the problems of high operating cost and power consumption, and achieve the effects of improving work efficiency, stable and reliable work, and good gas collecting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

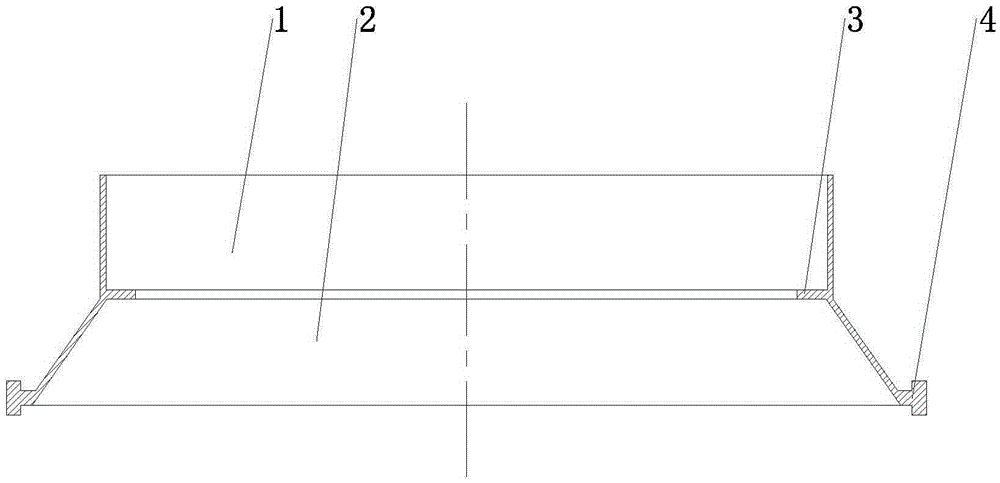

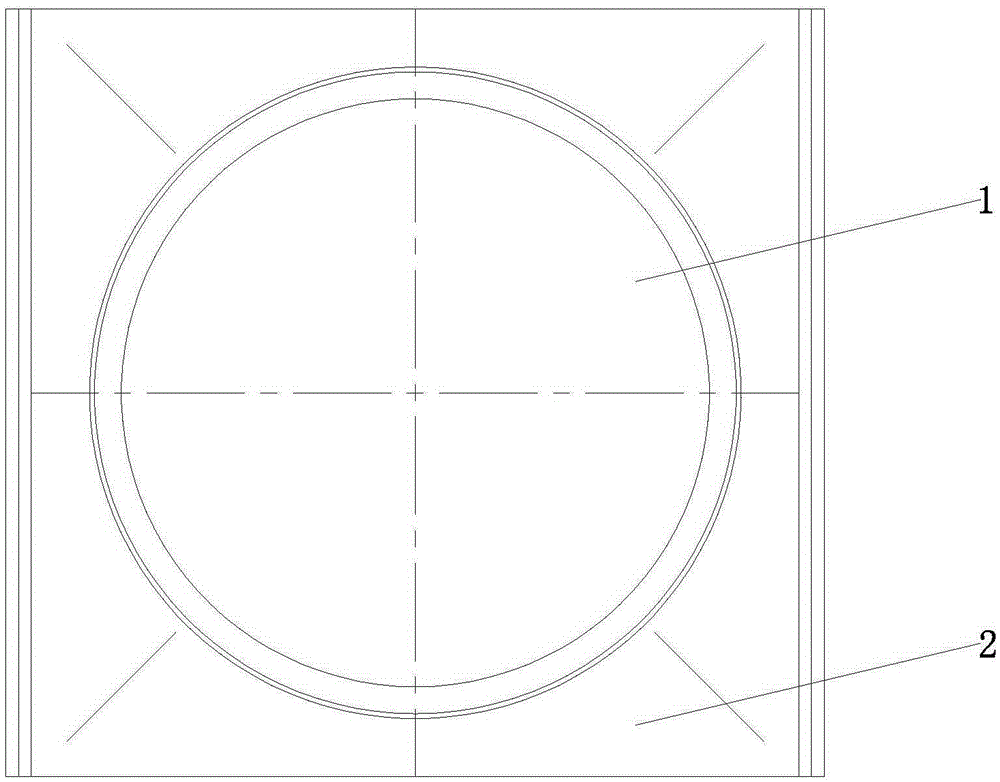

[0014] Such as Figure 1~2 As shown, the present invention mainly includes a delivery pipe body 1 and a collection cover body 2, the delivery pipe body 1 is cylindrical, and the lower end of the delivery pipe body 1 is connected to the collection cover body 2.

[0015] The collection cover body 2 is a cone-shaped cylindrical structure with a large diameter at one end and a small diameter at the other end. The smaller diameter end of the collection cover body 2 is connected to the delivery pipe body 1, and a slide button 4 is provided on the outside of the larger diameter end of the collection cover body 2. The collection cover body 2 can be fastened on the aeration hose through the sliding buckle 4 to form an effective seal.

[0016] The conveying pipe body 1 and the collecting cover body 2 are integrally formed.

[0017] The inner side of the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com