Catalyst and method for preparing ethylene carbonate from ethylene oxide and carbon dioxide

A technology of ethylene carbonate and ethylene oxide, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of low activity of heterogeneous catalysts , to achieve the effect of improving the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 12.1 g Cu(NO 3 ) 2 ·3H 2 O and 44.2 g Al(NO 3 ) 3 9H 2 O was dissolved in 300 mL of water, and 200 mL of an aqueous solution containing 25.2 g of anhydrous sodium carbonate was added thereto, the resulting precipitate was collected, washed with deionized water 3 times, 500 mL each time, and the obtained precipitate was dried in an oven at 120 °C for 24 hours Afterwards, calcined at 500°C for 5 hours to obtain CuO / Al 2 o 3 Mixed oxide catalyst MO-1, in which CuO and Al 2 o 3 The parts by weight are respectively 40 and 60.

Embodiment 2~23

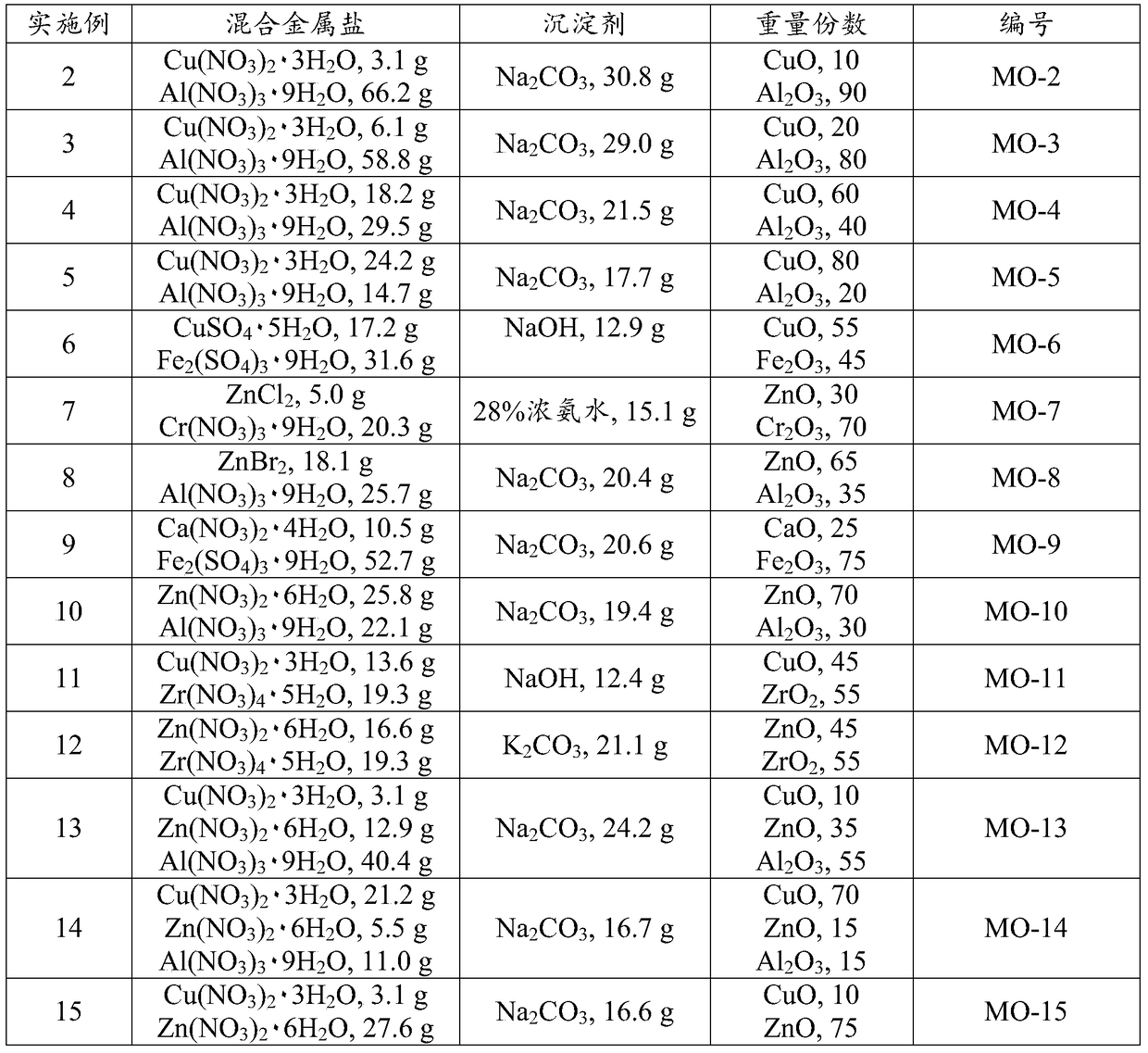

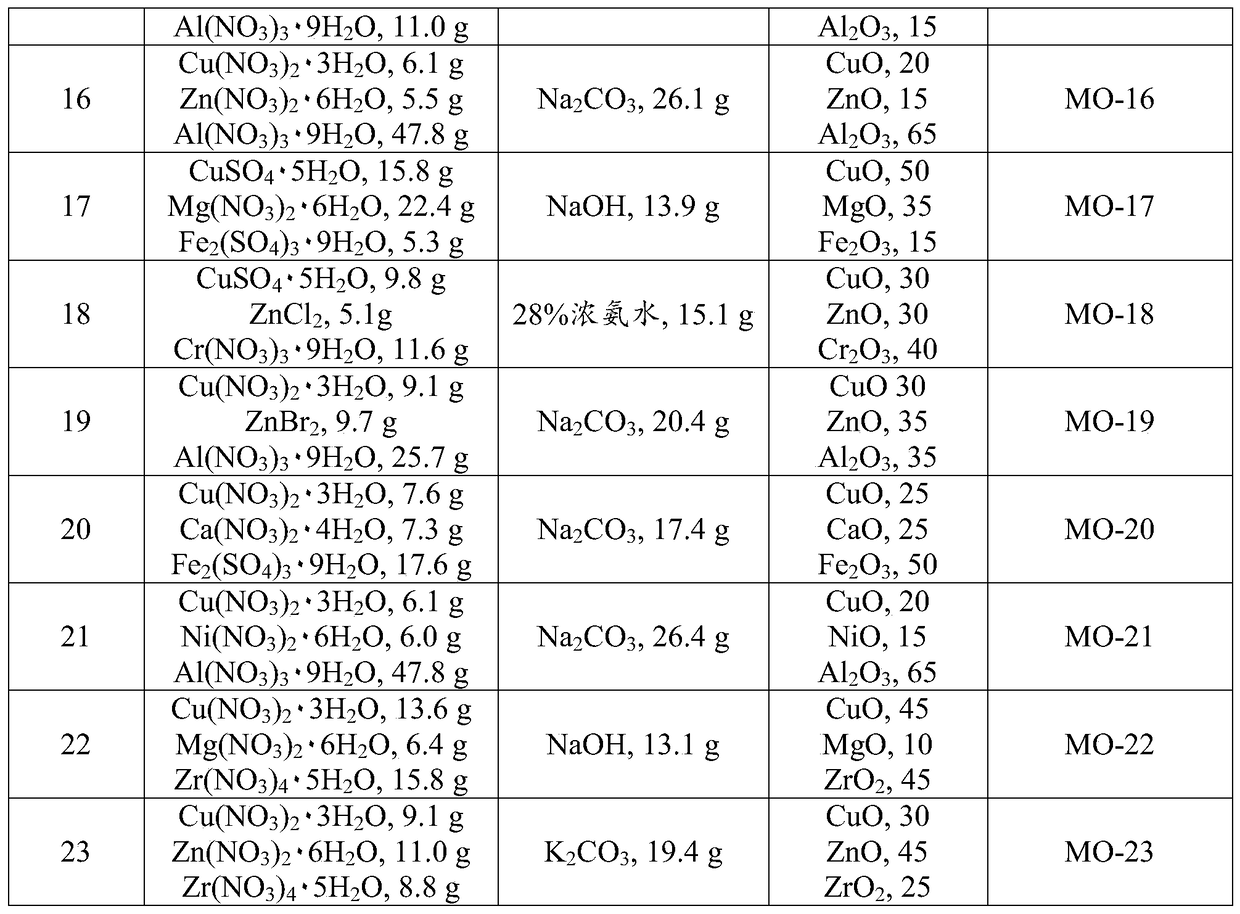

[0039] The mixed metal oxide catalyst obtained is shown in Table 1 by changing the type and amount of mixed metal salts and precipitants used, and keeping the rest of the conditions unchanged.

[0040] Table 1

[0041]

[0042]

Embodiment 24

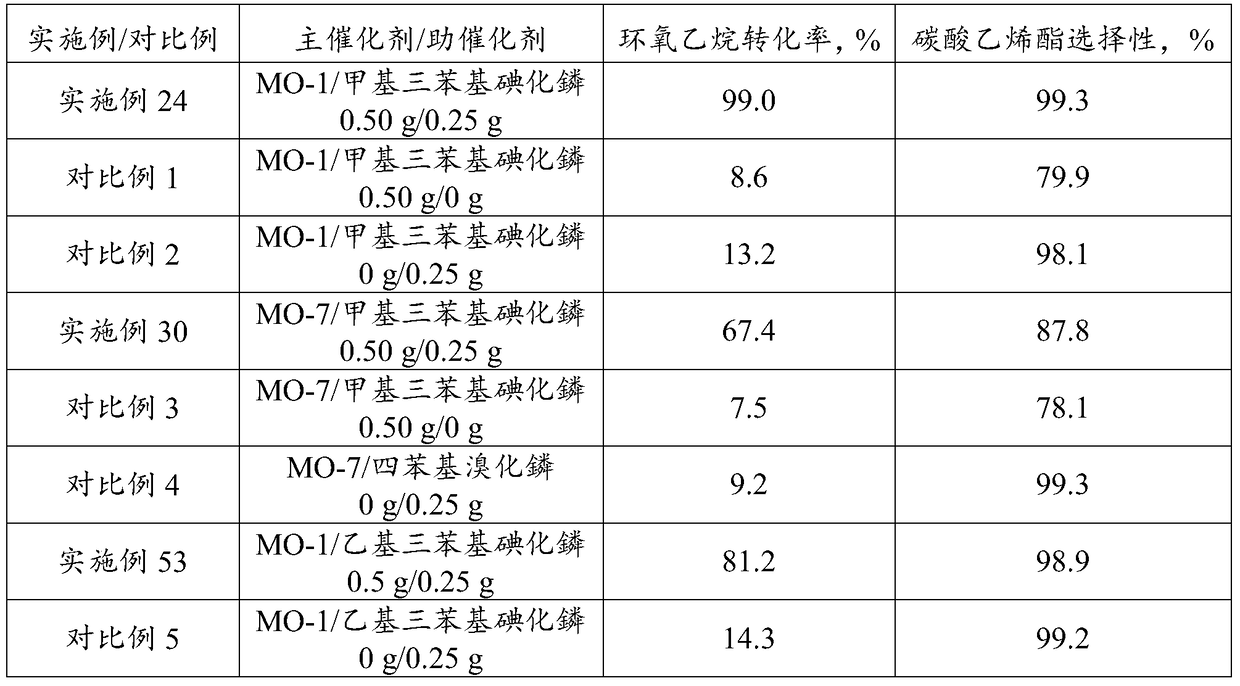

[0044] Take by weighing 0.50g MO-1 catalyst and 0.25g methyltriphenylphosphonium iodide prepared above [Example 1] and place in a 100mL stainless steel reaction kettle, use N 2 Replace the air in the reactor, then fill with 50.0g ethylene oxide, pass into CO 2 , keep the system pressure at 1.0MPa, stir for 1 hour and then raise the temperature to 120°C, add CO 2 , keeping the system pressure at 5.0MPa, cooling after 4 hours of reaction, and performing chromatographic analysis on the reaction product, it was found that the conversion rate of ethylene oxide was 99.0%, and the selectivity of ethylene carbonate was 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com