Method for extracting plant essential oil fragrance through water jet grinding and centrifugal membrane microwave distillation

A technology of water jet crushing and plant essential oil, which is applied in the direction of essential oil/fragrance, fat production, etc., to achieve the effect of increasing saturated vapor pressure and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

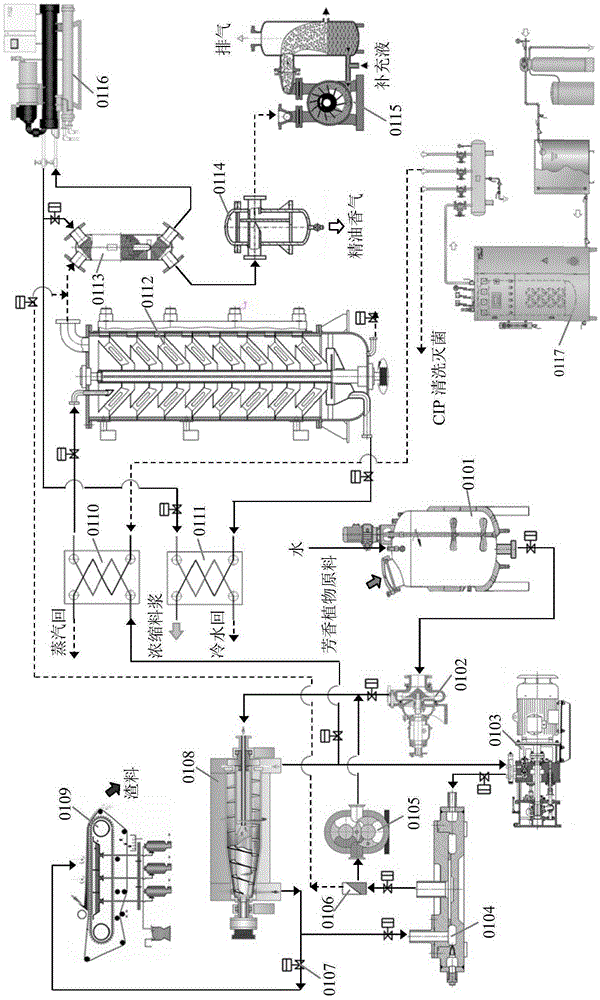

[0060] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

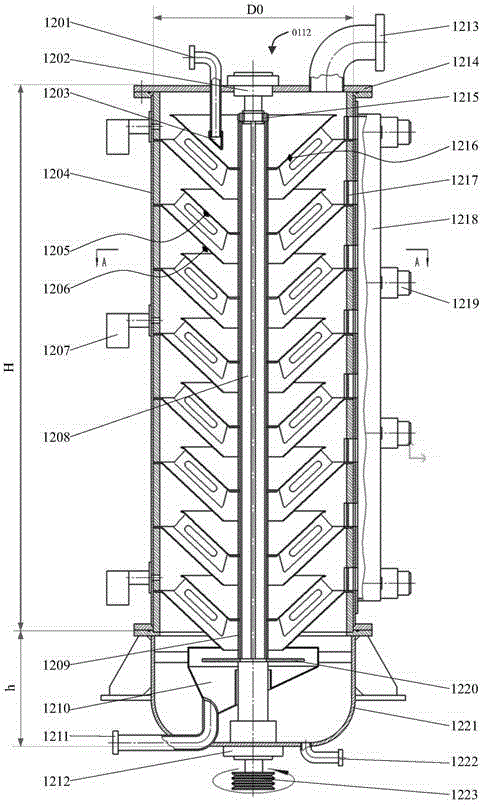

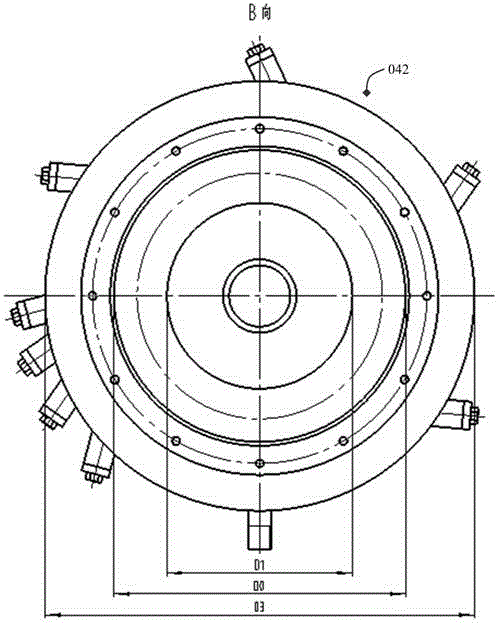

[0061] Such as figure 1 As shown, the present invention provides a method for extracting aromatic plant essential oils and aromas through water jet crushing and centrifugal membrane decompression and low temperature distillation. Plunger pump 0103, water jet mill for ultra-fine crushing of plants 0104, pulverized slurry delivery pump 0105, pulverized slurry separator 0106, flow control valve 0107, centrifugal separator 0108, filter dehydration device 0109, evaporation slurry pre Heater 0110, concentrated slurry cooler 0111, multi-layer disc centrifugal and gravity film-forming microwave evaporation device 0112, condenser 0113, separator 0114, vacuum unit 0115, chiller unit 0116, hot air source 0117.

[0062] The proces...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap