Composite bacterial liquid and preparation method thereof

A technology of compound bacterial liquid and mixed bacterial strains, which is applied in the preparation of compound bacterial liquid, the preparation method of compound bacterial liquid and the field of compound bacterial liquid, which can solve the problems of relatively little research on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

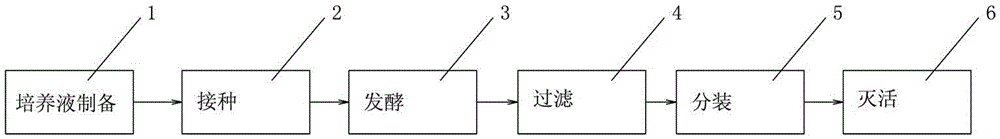

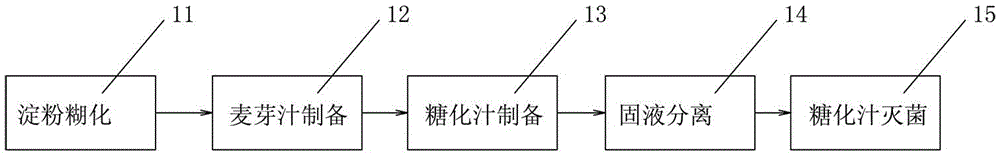

[0033] See figure 1 and figure 2 , the invention provides a method for preparing a composite bacterial solution, comprising the following steps,

[0034] (1), preparation of culture medium, take 20-30 parts by weight of malt powder, 60-80 parts of starch, and process as follows;

[0035] (11) Starch gelatinization, put the starch and water into the gelatinization pot according to the ratio of 1:2-3 parts by weight, raise the temperature to 90-100 degrees Celsius, keep stirring until the starch becomes a paste, and then use Water at 20-25 degrees Celsius adjusts the temperature of the gelatinized slurry to 68-73 degrees Celsius;

[0036] (12) Put the malt powder into the saccharification pot, move the slurry prepared in step (11) into the saccharification pot, fully mix the malt powder and the slurry while stirring, then let it stand, and Keep the temperature in the range of 64-66 degrees Celsius for 4-6 hours until the starch is completely saccharified; during the sacchari...

Embodiment 1

[0062] (1), preparation of culture medium, take 20 parts by weight of malt powder, 60 parts of starch, and process as follows;

[0063] (11) Starch gelatinization, put the starch and water into the gelatinization pot according to the ratio of 1:2-3 parts by weight, raise the temperature to 90-100 degrees Celsius, keep stirring until the starch becomes a paste, and then use Water at 20-25 degrees Celsius adjusts the temperature of the gelatinized slurry to 68-73 degrees Celsius;

[0064] (12) Put the malt powder into the saccharification pot, move the slurry prepared in step (11) into the saccharification pot, fully mix the malt powder and the slurry while stirring, then let it stand, and Keep the temperature in the range of 64-66 degrees Celsius for 4-6 hours until the starch is completely saccharified; during the saccharification process, iodine can be used for detection. If there is no reaction between iodine and starch in the iodine test, it means that the saccharification ...

Embodiment 2

[0075] (1), the preparation of culture medium, take 25 parts by weight of malt powder, 65 parts of starch, process according to the following method;

[0076] (11) Starch gelatinization, put the starch and water into the gelatinization pot according to the ratio of 1:2-3 parts by weight, raise the temperature to 90-100 degrees Celsius, keep stirring until the starch becomes a paste, and then use Water at 20-25 degrees Celsius adjusts the temperature of the gelatinized slurry to 68-73 degrees Celsius;

[0077] (12) Put the malt powder into the saccharification pot, move the slurry prepared in step (11) into the saccharification pot, fully mix the malt powder and the slurry while stirring, then let it stand, and Keep the temperature in the range of 64-66 degrees Celsius for 4-6 hours until the starch is completely saccharified; during the saccharification process, iodine can be used for detection. If there is no reaction between iodine and starch in the iodine test, it means tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com