Composite phase change material heat sink of metal fiber porous skeleton and manufacturing method thereof

A composite phase change material and metal fiber technology, which is applied in the direction of electrical components, circuits, electric solid devices, etc., can solve the problem of affecting the temperature control performance of phase change heat sinks, uniformly utilize the energy storage capacity of phase change materials, and have low thermal conductivity and other problems, to achieve the effects of large latent heat of phase change, ensuring thermal control performance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation method of the present invention is not limited thereto.

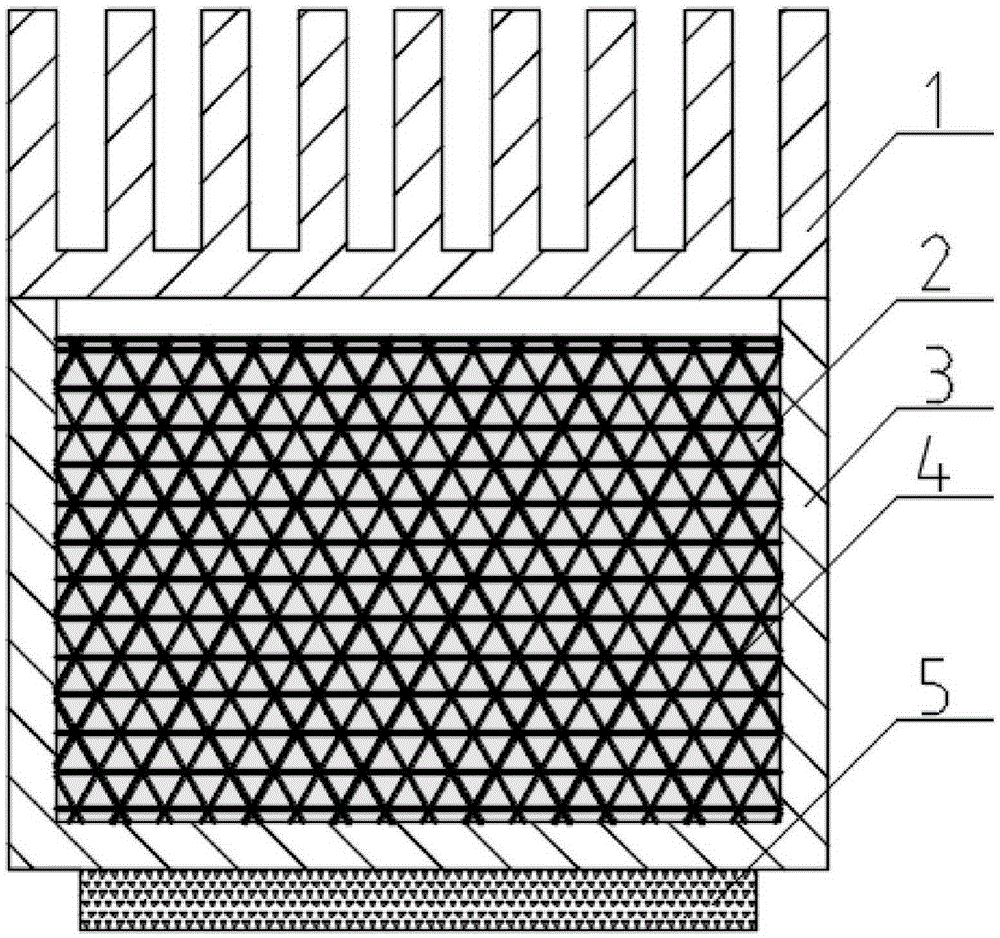

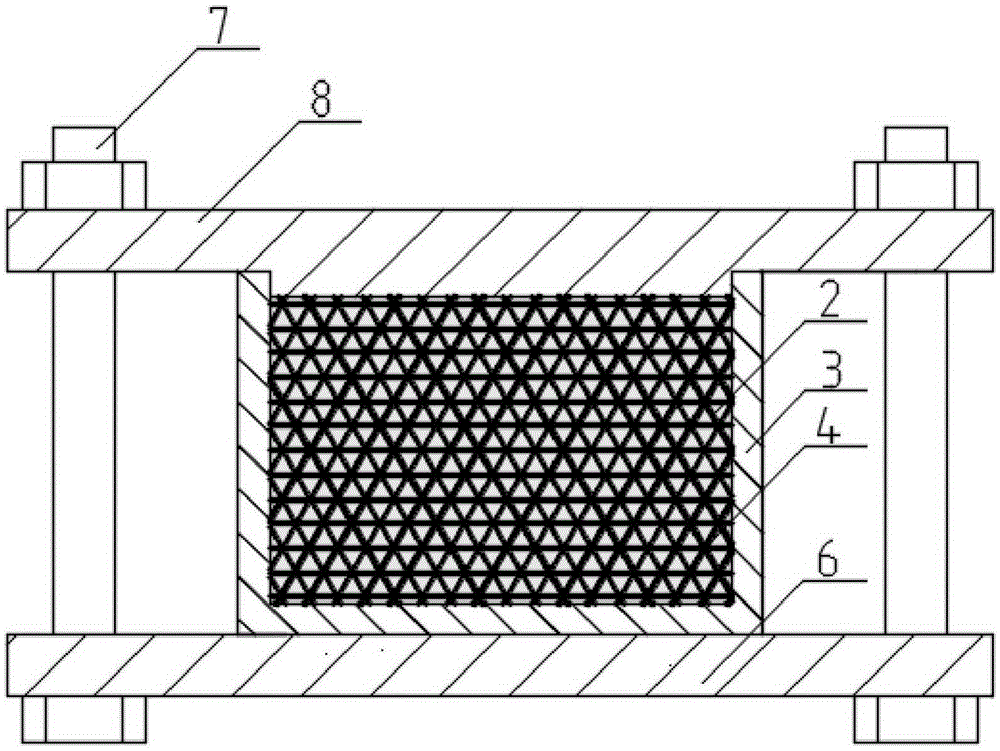

[0030] Such as figure 1 As shown, a metal fiber porous framework composite phase change material heat sink includes a metal fiber porous framework 4, a phase change material 2, a heat sink base 3, and a heat dissipation fin 1. The heat sink base 3 is provided with a cavity and a top The surface is provided with openings; the metal fiber porous framework 4 is sintered from metal fibers filled in the cavity of the heat sink base 3, and its porosity ranges from 75% to 98%, and is sintered into a whole with the heat sink base 3 The diameter of the metal fiber used for sintering is in the range of 50~400um, and the length is 15-30mm; the phase change material 2 is filled in the pores of the porous metal fiber framework 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com