A battery system and its assembly method

A battery system and assembly method technology, applied in secondary batteries, chemical instruments and methods, circuits, etc., can solve the problems of high battery operating temperature, hidden safety hazards, and increased hazard, achieve thermally induced flexibility, and improve use safety. , the effect of reducing the contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

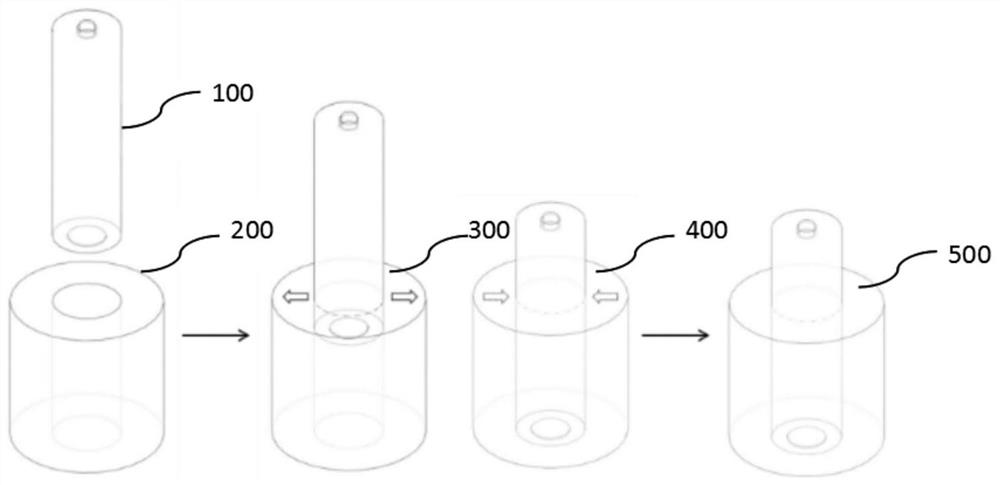

[0046] Example 1: Assembly of the battery system

[0047] A battery system includes a composite phase change material and a battery; the composite phase change material, by mass fraction, comprises 76% of paraffin wax, 19% of olefin block copolymer and 5% of expanded graphite; Interference fit; the battery is a cylindrical battery, the battery type is 18650.

[0048] The assembling method of the above battery system includes the following steps:

[0049] (1) Preparation of composite phase change material: heating paraffin and olefin block copolymer to 160°C and mixing, then gradually adding expanded graphite, stirring for 30 minutes to obtain a molten mixture, and then placing the molten mixture in a stainless steel mold (cylindrical) for molding, the molding pressure is 1kN / m 2 , the molding time is 10 minutes, cooled to room temperature (for example, 20 ° C), continued molding for 10 minutes, and then stripped to obtain a cylindrical composite phase change material;

[00...

Embodiment 2

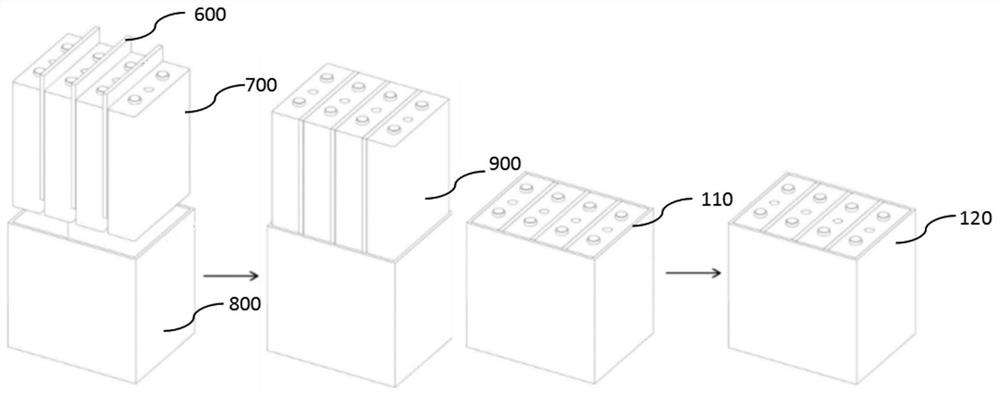

[0053] Example 2: Assembly of the battery system

[0054] A battery system includes a composite phase change material and a battery; the composite phase change material, by mass fraction, comprises 88% of paraffin, 10% of an olefin block copolymer and 2% of expanded graphite; the composite phase change material and the battery are used between Interference fit; cells are square cells.

[0055] The assembling method of the above battery system includes the following steps:

[0056] (1) Preparation of composite phase change material: heating paraffin and olefin block copolymer to 158°C and mixing, then gradually adding expanded graphite, stirring for 30 minutes to obtain a molten mixture, and then placing the molten mixture in a stainless steel mold (sheet) for molding, and the molding pressure is 1 kN / m 2 , the molding time is 10 minutes, cool to room temperature (for example, 20 ° C), continue molding for 10 minutes, and then release the film to obtain a sheet-like composite...

Embodiment 3

[0059] Example 3: Assembly of the battery system

[0060] Compared with Example 2, the only difference in Example 3 is that a plurality of battery cells are assembled into a plurality of through holes of a block-shaped composite phase change material at the same time, and a certain gap is left between the plurality of battery cells. The voids are filled by the composite phase change material, and the battery and the composite phase change material in each battery cell can also obtain a pressing force to maintain a close fit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com