Nodular cast iron fiber well lid and preparation method thereof

A technology of nodular cast iron and steel fiber, applied in artificial islands, underwater structures, buildings, etc., can solve problems such as uneven mixing of steel fiber and mortar, decrease in strength and durability, and achieve improved interface structure and section bonding, The effect of improving density and hardness and improving the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preparation steps of the present invention:

[0035]The cover plate is prepared by pouring mold method and adding steel fiber concrete three times, including the following steps:

[0036] (1) Dry mix cement, gravel and sand in the mixer and mix them with the solution prepared by water and water reducer to continue stirring to prepare mortar, reserve 1 / 3 of the mortar, add steel fiber to the remaining mortar in the mixer and mix evenly Preparation of steel fiber reinforced concrete;

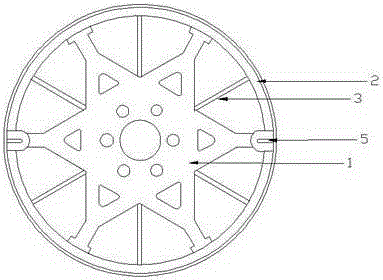

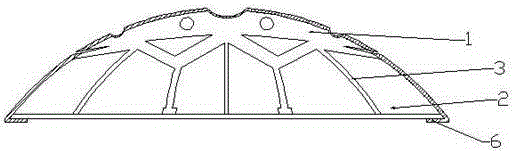

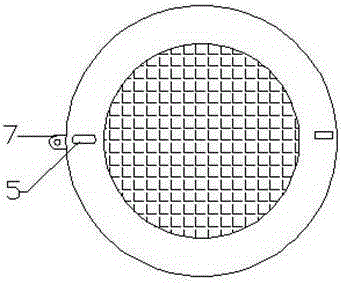

[0037] (2) Place the mold on the vibrating platen at the upper end of the vibrating machine, add half of the mortar to the mold and level it out, add a small amount of steel fiber concrete, and then put the ductile iron integrated manhole cover skeleton;

[0038] (3) Add half of the steel fiber concrete to the mold for the second time and vibrate for 5 minutes to 10 minutes;

[0039] (4) Then add all the remaining steel fiber concrete into the mold and vibrate for 5 minutes to 10 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com