Environment-friendly, thermal-insulation and heat-preservation wall body material

A technology of heat insulation and wall materials, which is applied to walls, building components, fire protection, etc., and can solve problems such as functional incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

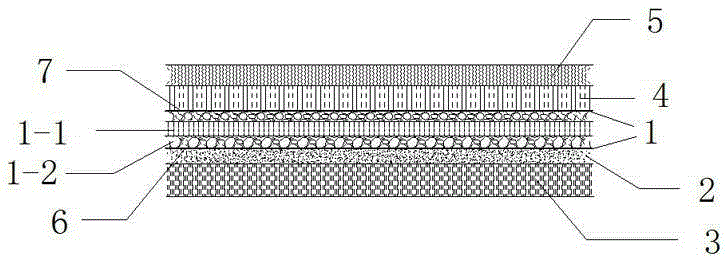

[0021] refer to figure 1 , an environmentally friendly heat insulation wall material, comprising a wall core layer 1, the inner side of the wall core layer sequentially includes a shock absorbing layer 2, a cement foam layer 3, and the outer side of the wall core layer sequentially includes a flame-retardant layer 4 and an outer layer Decorative layer 5.

[0022] The wall core layer 1 includes an inorganic keel 1-1 and a lightweight wood-plastic foam material 1-2 compounded with its exterior.

[0023] The inorganic keel 1-1 is a framework material formed by in-situ polymerization based on inorganic clay materials such as silicon, calcium, and magnesium, supplemented by silica gel materials. The preparation method is to add inorganic clay such as silicon, calcium and magnesium to the silica gel precursor, and then polymerize and cross-link the silica gel in situ to form a keel.

[0024] The lightweight wood-plastic foaming material 1-2 is made of thermoplastic polyethylene an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com