High-pumping-speed horizontal type oil pressure boosting pump

A horizontal oil and booster pump technology, applied in the field of oil booster pumps, can solve problems such as difficult processing, achieve good cooling effect, reduce electricity costs, and achieve high ultimate vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

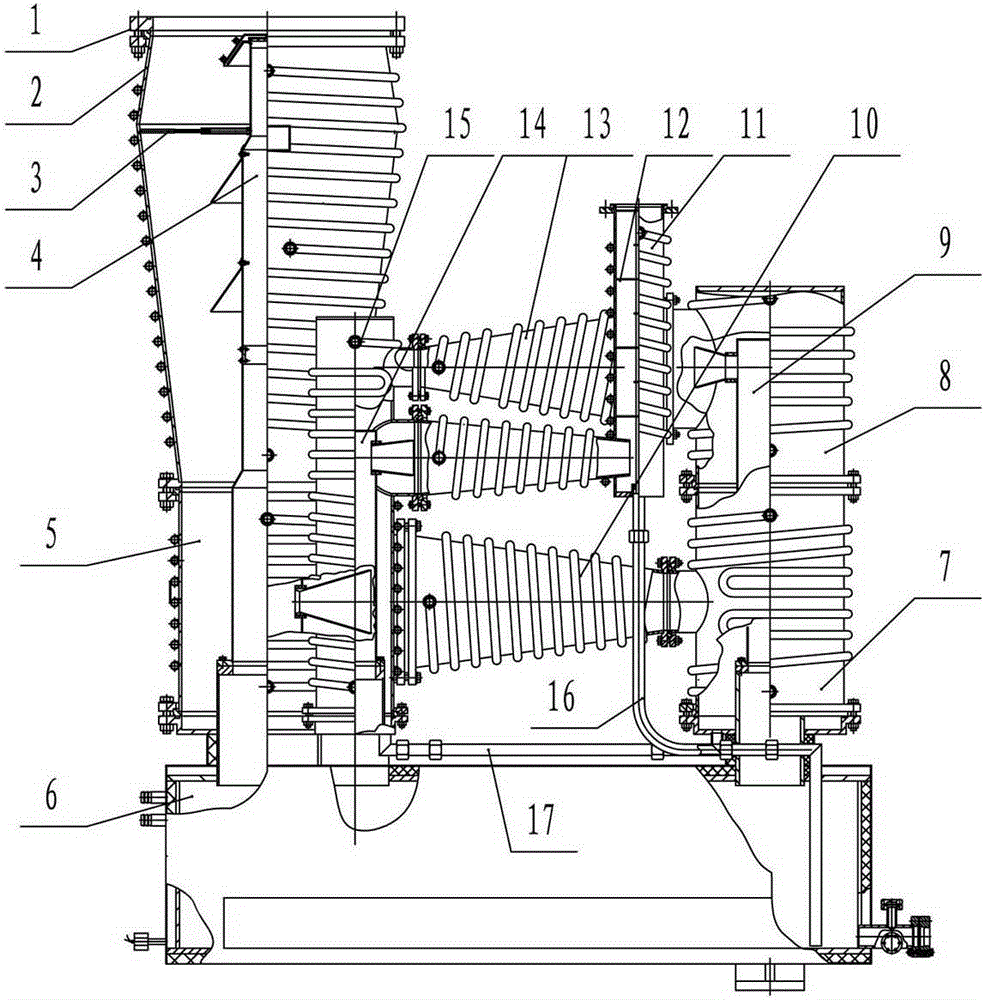

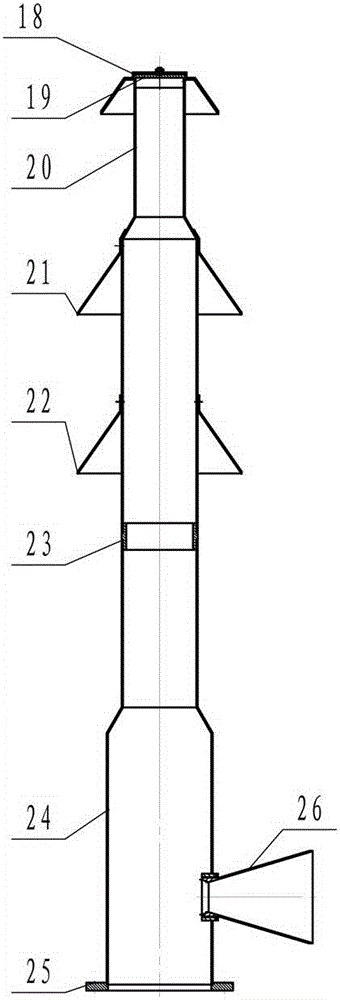

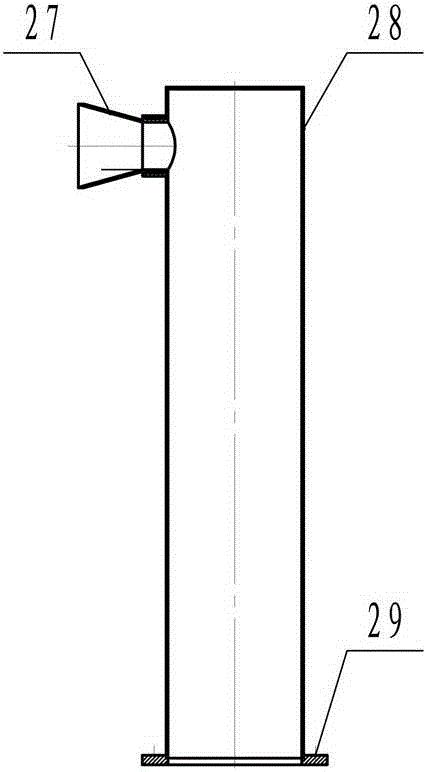

[0030] Such as figure 1 , Figure 8 , Figure 9 , Figure 10 , Figure 11As shown, the structure of the present invention's horizontal large pumping speed horizontal oil booster pump is as follows: an intermediate body 5, a fourth-stage lower injection body 7 and a fifth-stage injection body 15 are respectively installed on the boiler body 6, and the flange of the intermediate body 5 The main pump body 2 is arranged on the top, the oil deflecting cap 1 is arranged on the upper end of the main pump body 2, the fourth-stage upper injection body 8 is arranged on the upper end of the fourth-stage lower injection body 7, the intermediate body 5 and the lower part of the fourth-stage lower injection body 7 pass through the third-stage The diffuser channel 10 communicates, the upper part of the fifth-stage injector 15 communicates with the upper part of the fourth-stage upper injector 8 through the fourth-stage diffuser channel 13, and the middle part of the fifth-stage injector 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com