A Quantum Dot-Doped Fiber Optic Taper for Fluorescence Enhancement and Mixing

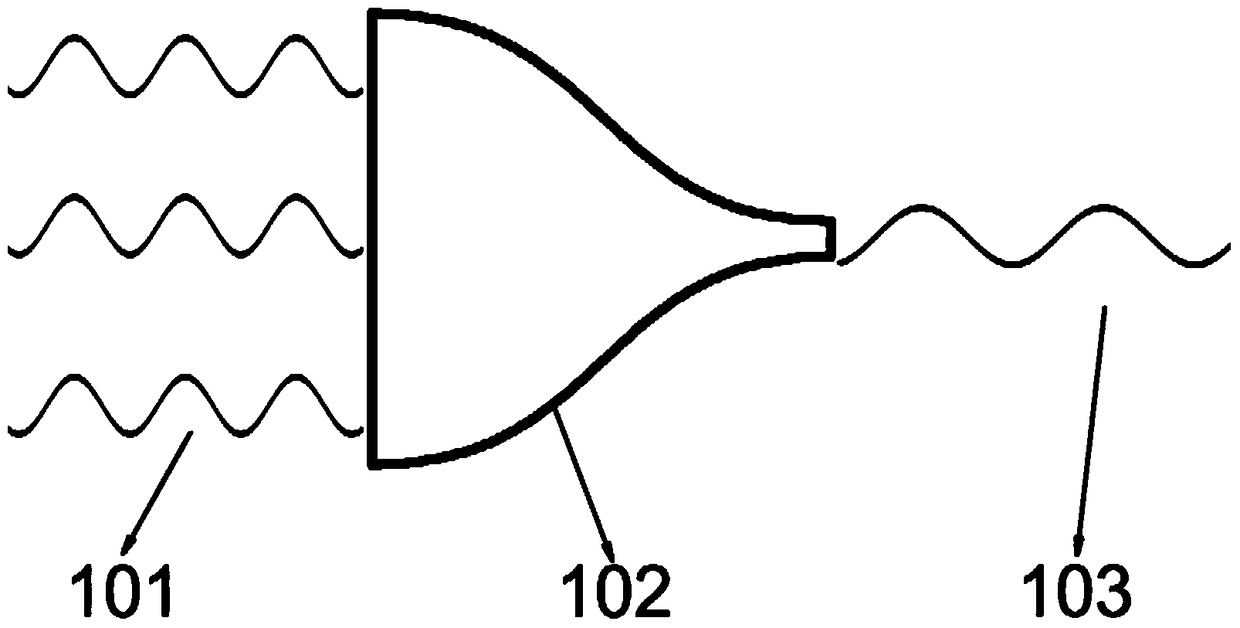

A fiber-doped and fluorescence-enhanced technology, which is applied to light guides doped with fluorescent agents, fiber optic light guides, light guides, etc., can solve the problem of low fluorescence efficiency of a single quantum dot-doped fiber, complex monochromatic light source technology, and high cost. problem, to achieve the effect of small output spot area, high output optical power density, and simple installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a quantum dot-doped fiber optic cone for fluorescence enhancement:

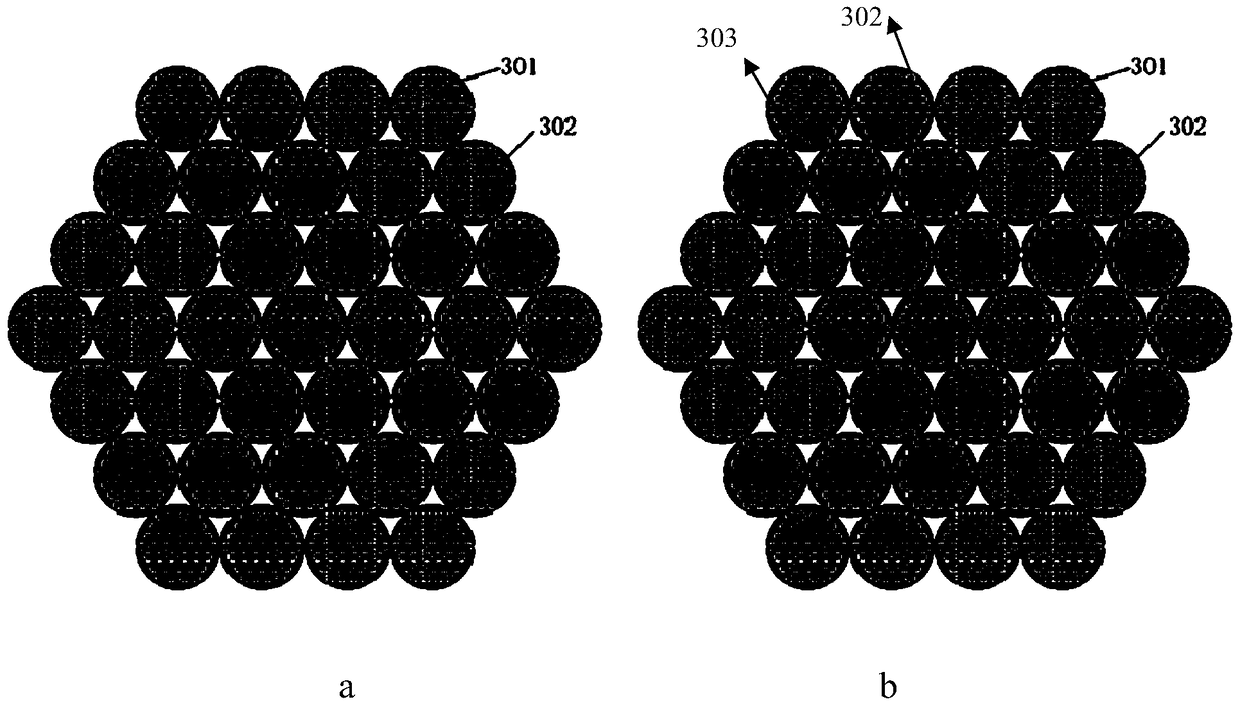

[0030] (1) Preparation of optical fiber monofilament: Weigh 70g of the raw material of quantum dot-doped optical fiber (SiO 2 :B 2 o 3 :Al 2 o 3 : CaCO 3 : Na 2 CO 3: the molar ratio of ZnS is 60:16:4:10:10:1), mix evenly, then put it in a crucible and keep it warm at 1350°C for 1 hour in a glass melting furnace to obtain molten glass; pour the molten glass Quench on a steel plate with a preheating temperature of 400°C, and after cooling to room temperature, cut and polish the glass to obtain a glass rod with a diameter of 2mm, which is the core of the quantum dot-doped glass optical fiber; then insert the core into the quartz material In the prepared cladding tube, the optical fiber is drawn with a fiber drawing machine. The drawing condition is that the temperature is 800°C and the drawing speed is 100r / min to obtain a quantum dot-doped optical fiber monofilament with a ...

Embodiment 2

[0034] A method for preparing a quantum dot-doped fiber optic cone for fluorescence mixing:

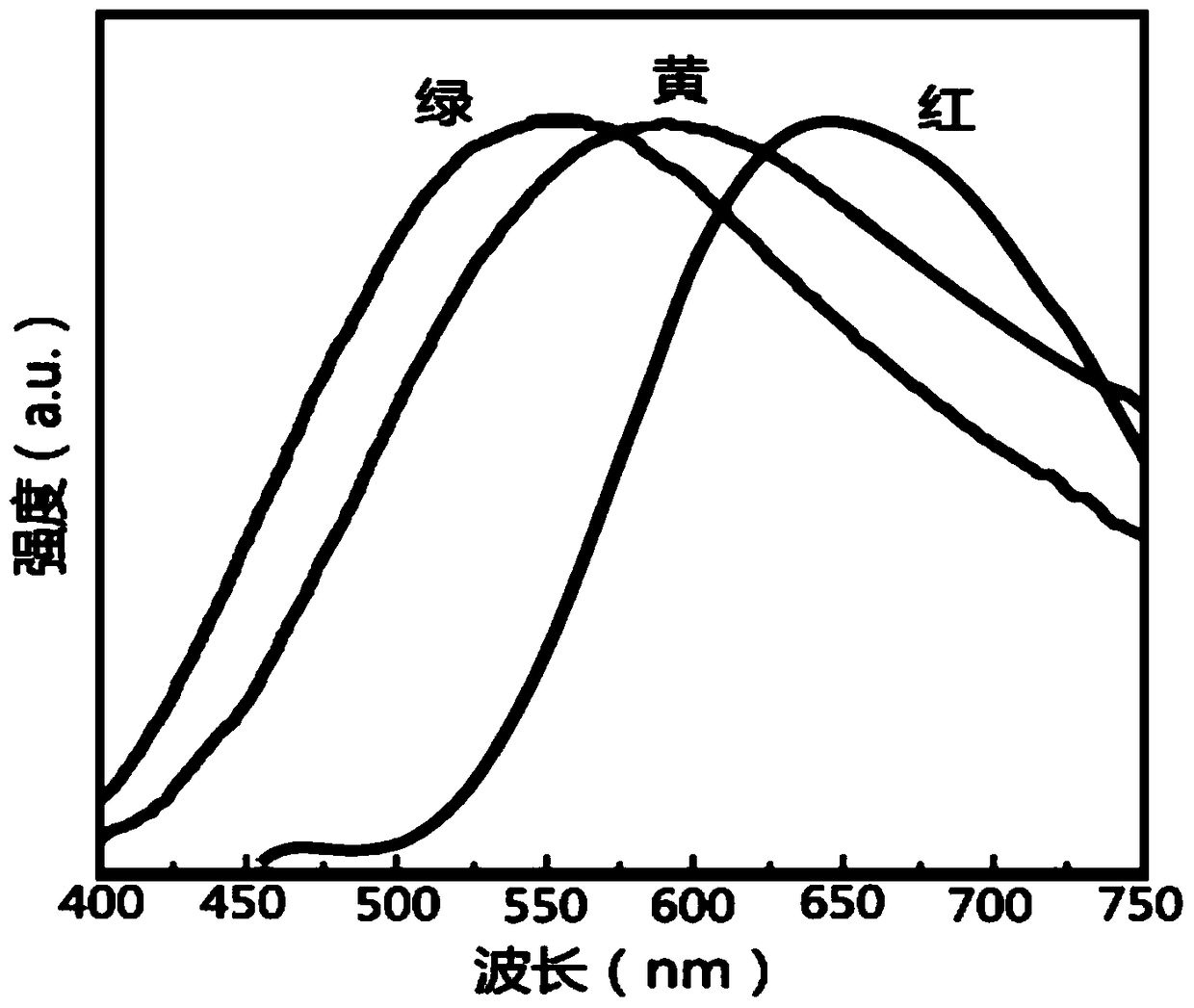

[0035] (1) Preparation of fiber monofilaments capable of exciting red fluorescence and green fluorescence fibers: Weigh 70 g of quantum dot-doped optical fiber raw materials (SiO 2 :B 2 o 3 :Al 2 o 3 : CaCO 3 : Na 2 CO 3 : The molar ratio of ZnS is 60:16:4:10:10:1) and the raw material (SiO 2 :B 2 o 3 :Al 2 o 3 : CaCO 3 : Na 2 CO 3 : The molar ratio of ZnS:PbO is 60:16:4:10:10:1:0.8), respectively mixed evenly, and then placed in two crucibles and kept at 1350°C for 1 hour in a glass melting furnace to obtain glass melting pour the molten glass on a steel plate with a preheating temperature of 400°C and quench it. After cooling to room temperature, the glass is cut and polished to obtain a glass rod with a diameter of 1 mm, which is the core of a quantum dot-doped glass optical fiber. ; Insert the fiber core into the cladding tube made of quartz material, and then draw ...

Embodiment 3

[0039] A method for preparing a quantum dot-doped fiber optic cone for fluorescence enhancement:

[0040] (1) Preparation of optical fiber monofilament: Weigh 70g of the raw material of quantum dot-doped optical fiber (SiO 2 :B 2 o 3 :Al 2 o 3 : CaCO 3 : Na 2 CO 3 : the molar ratio of PbS is 60:16:4:10:10:0.5), mix evenly, then place it in a crucible and keep it warm at 1350°C for 1 hour in a glass melting furnace to obtain a glass melt; pour the glass melt Quench on a steel plate with a preheating temperature of 400°C, and after cooling to room temperature, cut and polish the glass to obtain a glass rod with a diameter of 1.6mm, which is the core of the quantum dot-doped glass optical fiber; then insert the core into the quartz In the cladding tube prepared by the material, the optical fiber is drawn by a fiber drawing machine, the drawing condition is 800°C, the drawing speed is 100r / min, and a quantum dot-doped optical fiber monofilament with a diameter of 100 μm is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com