Solar crystalline silicon cell rework sheet processing technology

A technology of crystalline silicon cells and processing technology, applied in circuits, electrical components, sustainable manufacturing/processing, etc., to achieve the effect of reducing the proportion of defective wafers, flexible processing, and avoiding flower crystals and dark lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A solar crystalline silicon cell rework sheet processing process of the present invention, the solar crystalline silicon cell rework sheet is taken from the oxidizable rework sheet in Table 1.

[0030] Table 1 Classification of reworked sheets before rework processing

[0031] Oxidizable rework sheet Quantity (pieces) Textured rework sheet Quantity (pieces) Unclean 233 Abnormal wet sheet 156 Coating failure film 2108 Little white dot 384 The refractive index and film thickness exceed the standard 124 Handprint film after coating 234 Abnormal square resistance 553 Extensive dirt 105 - burnt 106 - Weight loss or suede abnormalities 30 - oil patch 167

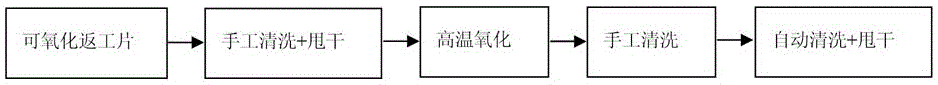

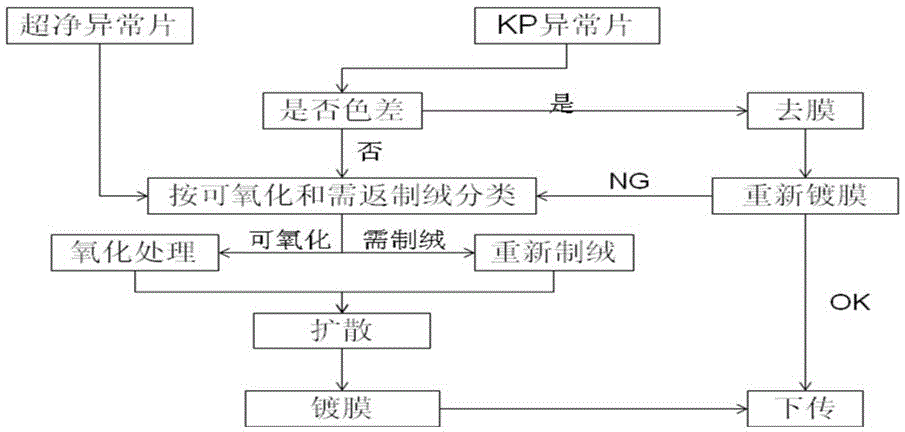

[0032] Such as figure 1 As shown, the solar crystalline silicon cell rework sheet processing technology of the present invention comprises the following steps:

[0033] (1) Manual cleaning + spin-drying: put the oxidizable rework sheet in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com