Bonding wire cathode passivation protecting treatment technology

A technology of protection treatment and bonding wire, which is applied in the field of cathodic passivation protection of bonding wires, can solve the problems of silver bonding wires such as reduced conductivity, reduced light reflection, and large surface roughness, without affecting the surface shape. Good appearance and appearance, maintain brightness, and good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

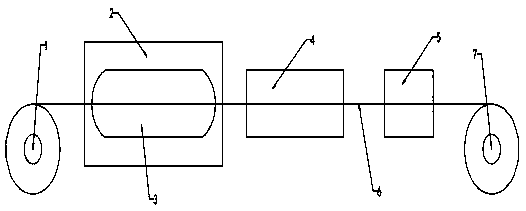

[0026] see figure 1 , in Embodiment 1 of the present invention, a cathodic passivation protection treatment process for bonding wires, comprising the following steps: drawing the bonding wire raw material core as a raw wire, and annealing the drawn bonding wire precursor 6 1. Use trivalent chromium cathode passivation solution to passivate the bonded wire precursor 6 after annealing, and use deionized water in the cleaning box 4 for the bonded wire precursor 6 passivated by trivalent chromium cathode passivation solution Cleaning, drying the cleaned bonding wire precursor 6 in the drying box 5 and rewinding and packaging the dried bonding wire precursor 6 through the take-up wheel 7 .

[0027] Further, the specific implementation method of drawing the raw material core of the bonding wire is: rough drawing and fine drawing of the raw material core of the bonding wire with a diameter of 2000 μm to 2500 μm, and draw it to a diameter of 25 μm.

[0028] Further, the specific impl...

Embodiment 2

[0032] see figure 1 , in embodiment 2 of the present invention, a kind of cathodic passivation protection treatment process of bonding wire, it comprises the following steps: carry out raw wire drawing to bonding wire raw material core, anneal to the bonded wire raw wire 6 after drawing 1. Use trivalent chromium cathode passivation solution to passivate the bonded wire precursor 6 after annealing, and use deionized water in the cleaning box 4 for the bonded wire precursor 6 passivated by trivalent chromium cathode passivation solution Cleaning, drying the cleaned bonded wire precursor 6 in the drying box 5 and rewinding and packaging the dried bonded wire precursor 6 through the take-up wheel 7 .

[0033] Further, the specific implementation method of drawing the raw material core of the bonding wire is: rough drawing and fine drawing of the raw material core of the bonding wire with a diameter of 2000 μm to 2500 μm, and draw it to a diameter of 25 μm.

[0034] Further, the s...

Embodiment 3

[0038] see figure 1, in embodiment 3 of the present invention, a kind of cathodic passivation protection treatment process of bonding wire, it comprises the following steps: carry out raw wire drawing to bonding wire raw material core, carry out annealing to the bonded wire raw wire 6 after drawing 1. Use trivalent chromium cathode passivation solution to passivate the bonded wire precursor 6 after annealing, and use deionized water in the cleaning box 4 for the bonded wire precursor 6 passivated by trivalent chromium cathode passivation solution Cleaning, drying the cleaned bonding wire precursor 6 in the drying box 5 and rewinding and packaging the dried bonding wire precursor 6 through the take-up wheel 7 .

[0039] Further, the specific implementation method of drawing the raw material core of the bonding wire is: rough drawing and fine drawing of the raw material core of the bonding wire with a diameter of 2000 μm to 2500 μm, and draw it to a diameter of 20 μm.

[0040] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com