High-power all-fiber laser based on multi-core fiber

A multi-core optical fiber and laser technology, applied to the structure/shape of optical resonators, the structure/shape of active media, etc., can solve the problem of low pump coupling absorption efficiency, the laser system is not an all-fiber structure, and cannot guarantee the stability of the laser system issues such as safety and reliability, and achieve the effect of avoiding fiber burnout and ensuring beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

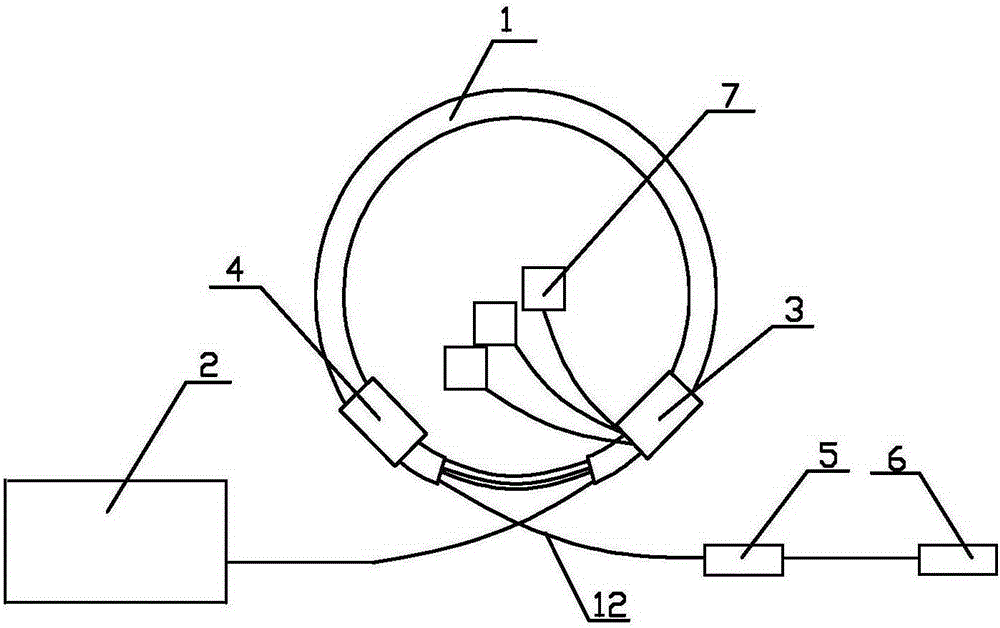

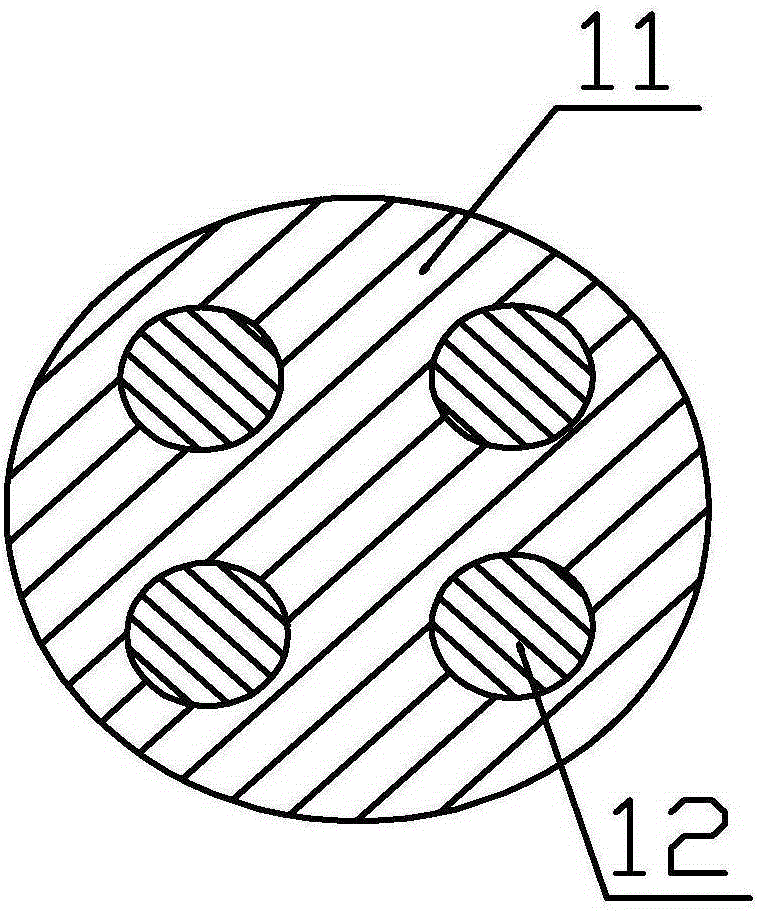

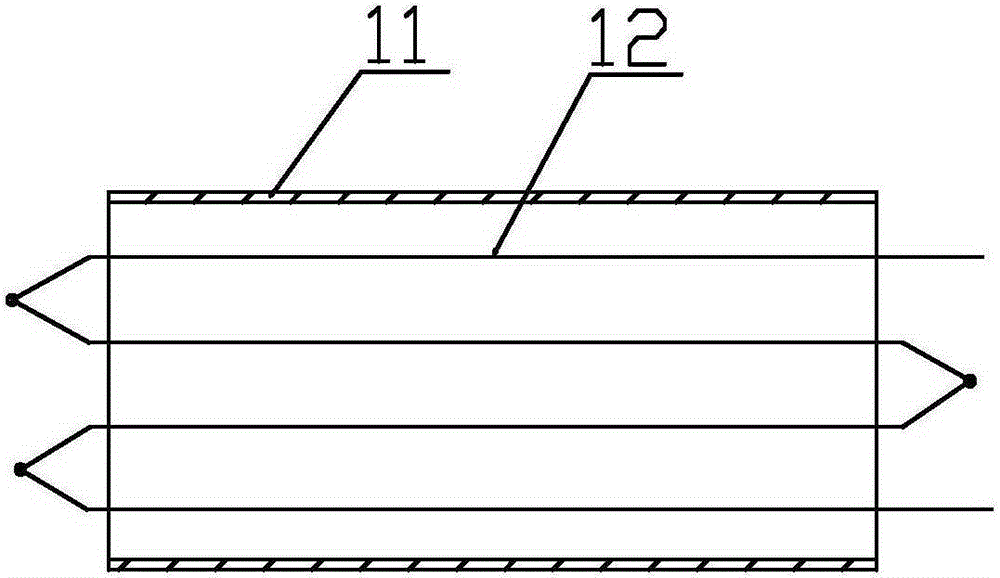

[0028] Such as figure 1 As shown, a high-power all-fiber laser based on a multi-core fiber includes a seed source 2, a pump combiner 3, an end cap 6, a pump source 7, a multi-core fiber 1, a cladding power stripper-4 and Cladding power stripper two 5, described multi-core optical fiber 1 comprises stripping the cladding 11 of two ends and inner multiple fiber cores 12, the end points of multiple fiber cores 12 are mutually fused into a single fiber core, described The part of the single fiber core located outside the cladding layer 11 has two endpoints, the two endpoints are respectively the input end and the output end, and the input end is fused with the seed source 2, and the signal light sent by the seed source 2 is sent by the input end After entering the multi-core optical fiber 1, the output end is fused with the end cap 6, the signal light is amplified by the multi-core optical fiber 1, and then output from the output end, the cladding 11 of the multi-core optical fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com