Wire rod for manufacture of steel wire for pearlite structure bolt having tensile strength of 950-1600 mpa, steel wire for pearlite structure bolt having tensile strength of 950-1600 mpa, pearlite structure bolt, and methods for manufacturing same

A technology of tensile strength and manufacturing method, which is applied in the direction of bolts, manufacturing tools, nuts, etc., can solve the problems that have not been established and cannot fully improve the hydrogen embrittlement resistance, and achieve the effect of excellent hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

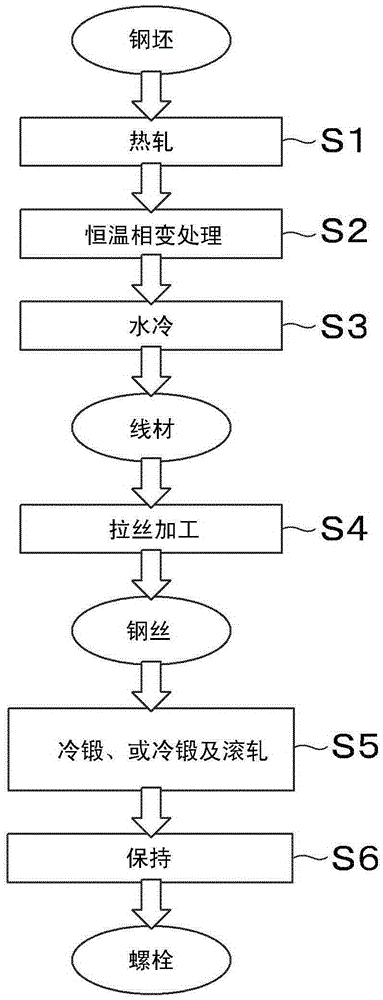

Method used

Image

Examples

Embodiment 1

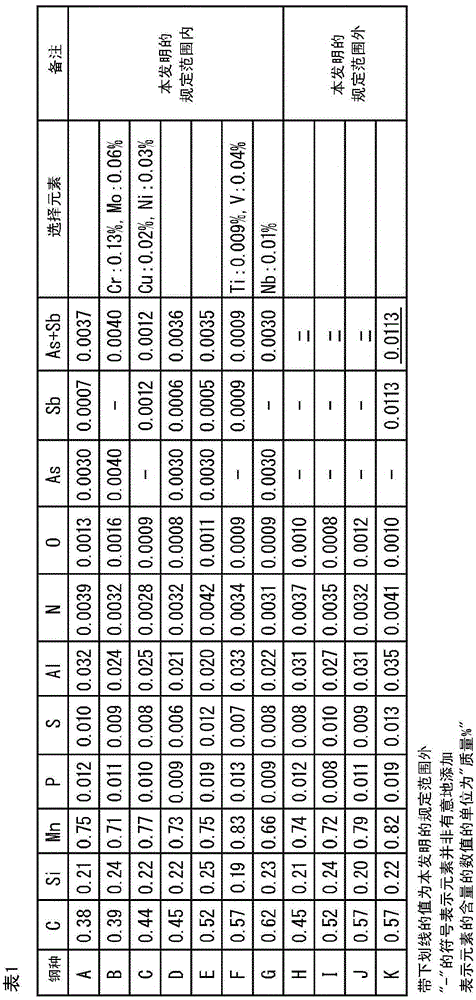

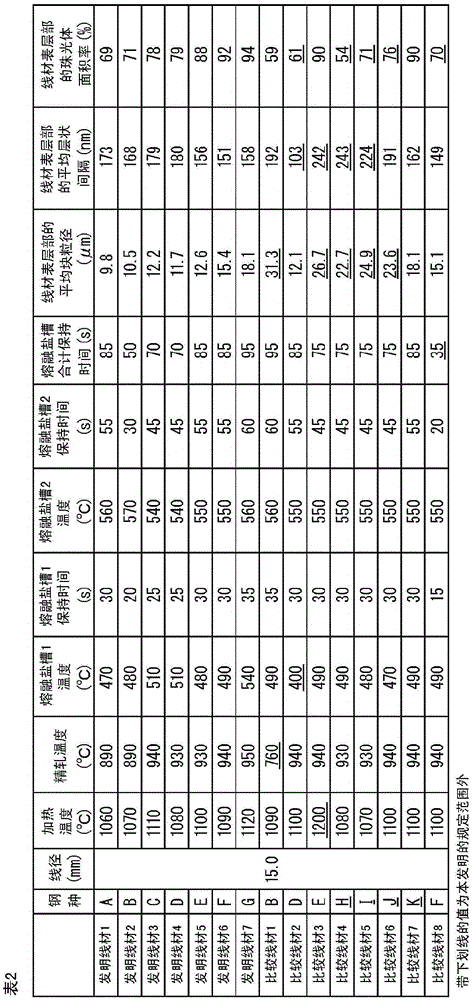

[0143] Steel slabs having the composition shown in Table 1 were heated and subjected to hot rolling to form wire rods, and the wire rods were subjected to constant temperature transformation treatment and subsequent cooling. At this time, the cooling start temperature of all the inventive wire rods and comparative wire rods was set to 450°C, and the cooling stop temperature was set to 280°C. The average block particle diameter, average lamellar interval, and pearlite area ratio of the surface layer portion (the region from the surface of the wire rod to a depth of 4.5 mm) of the obtained inventive wire rod and comparative wire rod were measured. The average block size of the pearlite block in the surface layer of the wire rod is measured by first measuring the average value of the circle-equivalent diameter of the pearlite block at a depth of 4.5 mm from the surface in the cross section of the wire rod at 45° intervals using an EBSD apparatus, Next, the measurement results at ...

Embodiment 2

[0149] Invention wires 1 to 7 and comparative wires 1 to 7 shown in Table 2 were subjected to wire drawing with a total reduction of area of 5 to 70% to produce steel wires, and the ultimate compressibility was measured. The results are shown in Table 3.

[0150]The ultimate compressibility is an index indicating cold workability. The measurement of ultimate compressibility is performed by the following procedure. A sample having a diameter D×height of 1.5D was produced by machining from the drawn steel wire. The end face of this sample was constrained and compressed using a die having concentric grooves. The maximum compressibility without cracks was taken as the ultimate compressibility of the sample.

[0151]

[0152] Comparative steel wires 1, 3, 4, 5, and 6 in which the average block diameter of the surface portion of the steel wire deviates from the range of the present invention, and comparative steel wires in which the average aspect ratio of pearlite block gra...

Embodiment 3

[0154] Inventive steel wires 1 to 7 and comparative steel wires 1 to 9 shown in Table 3 were processed into flanged bolts by cold forging. After processing, these bolts were maintained at 300 to 450° C. to manufacture bolts. The temperature holding time of all the bolts was set to 30 minutes. Table 4 shows the results of measuring the tensile strength, yield stress ratio, and hydrogen embrittlement resistance of the shaft portion of the bolt.

[0155] The evaluation of hydrogen embrittlement resistance was performed by the following procedure. First, 0.5 ppm of diffusible hydrogen was contained in the sample by electrolyzing the sample with hydrogen. Next, in order to prevent hydrogen from being released from the sample into the atmosphere during the test, the sample was plated with Cd. Thereafter, a load of 90% of the maximum tensile load of the sample was applied to the sample in the air. A sample that did not break after 100 hours was judged to be a sample with good hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com