Steel structure numerical control assembly center

A technology of steel structure and steel structure frame, which is applied in the direction of auxiliary equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as inability to adjust at will, defects in the quality of produced products, and the adjustment of tooling error is not very large, etc. Achieve good economic and social benefits, reduce necessary work and work difficulty, and improve the effect of equipment operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

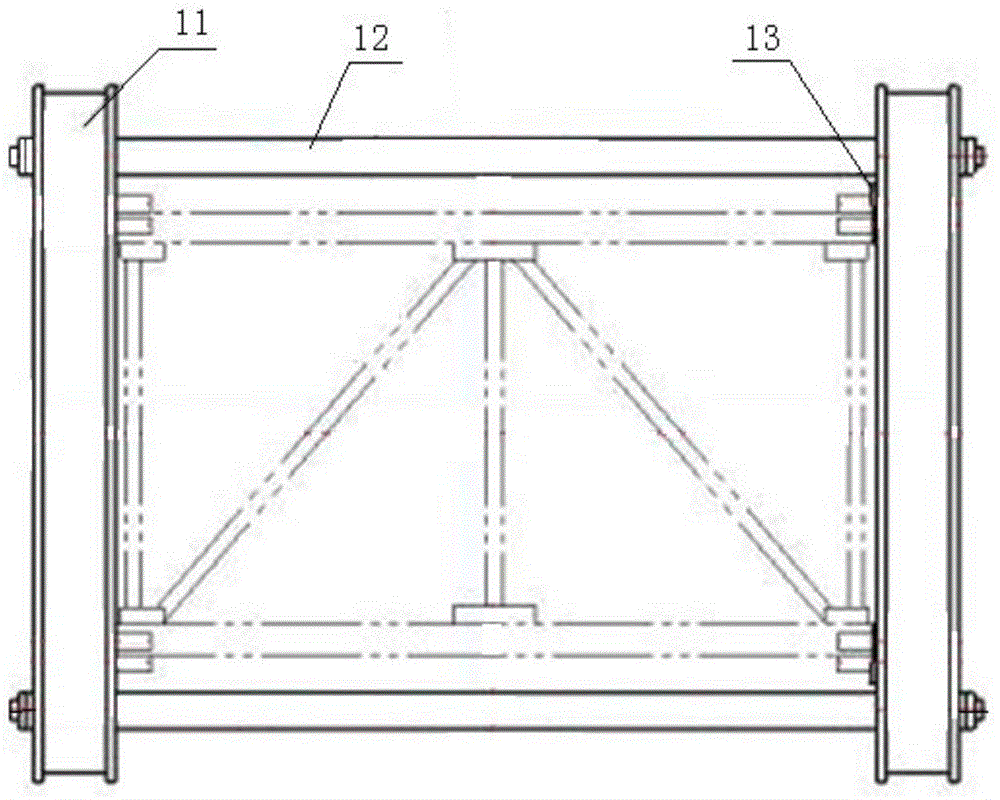

[0061] Embodiment one, such as Figure 5 , Image 6 As shown, when the present invention is in use, at first several sections of steel structure frames 16 are placed under the reinforced foundation, and they are spliced into elongated frames, pads are placed on the bottom of the frame to adjust pads 17, and then the steel frame is fixed by anchor bolts. The structural frame 16 is secured to the ground. The fixing device 18 is fastened on the steel structure frame 16 with the T-shaped fixed seat 25 as a positioning reference, and the two sides of the T-shaped fixed seat 25 are respectively equipped with a rack 27 and a magnetic scale 26, and the rack 27 and the gear on the mobile device 19 Group 30, servo motor 31 and reducer 32 are combined into a set of control system. The moving device 19 can move arbitrarily on the slide rail 29 through the slider 28 and the control system. The moving distance can be determined by the sensor 262 on the magnetic scale 26. The moving dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com