Packaged treatment method capable of reducing hardness of grey water and reducing volume of grey water discharged out by system

A complete set of treatment and gray water technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of large amount of drainage and replenishment water in the coal gasification system, which affects the long cycle of the coal gasification system Continuous and stable operation and other issues to achieve the effect of alleviating severe scaling, improving water cycle utilization rate, and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with example and accompanying drawing, the present invention is further described.

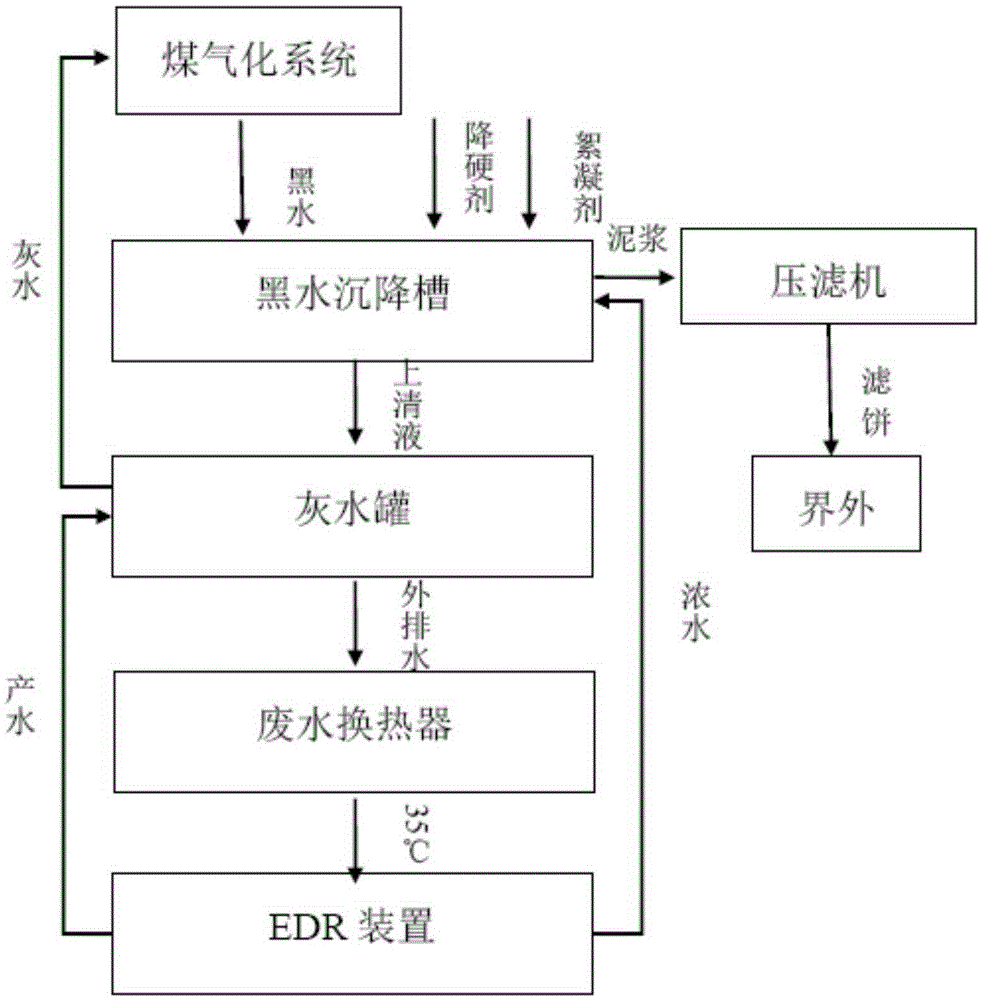

[0015] see figure 1 , a complete set of treatment process to reduce the hardness of gray water in the coal gasification system and significantly reduce the amount of gray water discharged from the system. Enter the EDR unit. When gray water flows through the EDR device, due to the directional migration of ions, two parts are formed: product water with very low ion content and concentrated water with high ion concentration. Among them, the produced water is returned to the gray water tank and reused in the coal gasification system, thereby reducing the concentration of various scaling ions in the water of the coal gasification system; the concentrated water enters the settling tank, and calcium salts, magnesium salts, etc. are produced under the action of the hardening agent The sediment is flocculated and settled to the bottom of the settling tank together with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com