Coal gasification black/gray water system treatment method capable of lowering hardness, saving water and reducing sewage discharge

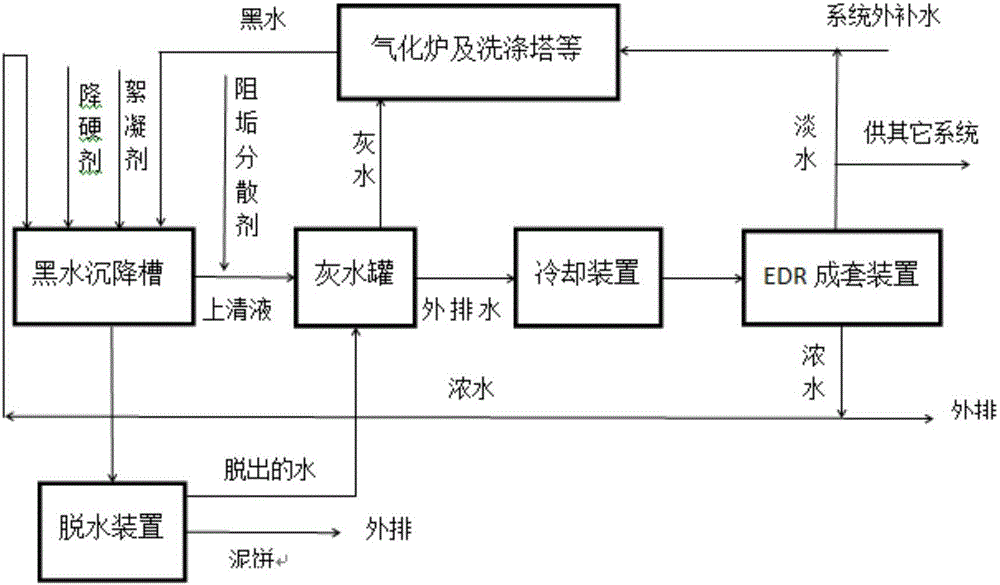

A treatment method and coal gasification technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The problem of large amount of water replenishment can achieve the effect of improving the utilization rate of water circulation, alleviating serious scaling and reducing the failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] For the coal gasification system of a chemical plant, the working condition of black gray water is: Ca in gray water 2+ About 1000mg / L, HCO 3 - About 30mmol / L; the system discharges gray water from the gray water tank to about 720,000m 3 / year, the amount of fresh water replenishment is about 864000m 3 / year. The long-term operation of gray water under high-hardness and high-alkali conditions has caused serious deposits and fouling in key parts of the system such as lock bucket flushing water pipelines, chilled water pipelines, scrubber trays, and waste water heat exchangers, seriously affecting the long-term cycle of the coal gasification system Continuous and stable operation makes the company bear huge economic and environmental pressure. Aiming at the problems encountered in the above-mentioned production, adopting the treatment method of reducing hardness, saving water and reducing pollution in the coal gasification system of the present invention, the gray wat...

Embodiment 2

[0024] For the coal gasification system of a chemical plant, the working condition of black gray water is: Ca in gray water 2+ About 600mg / L, HCO 3 - About 15mmol / L; the system discharges gray water from the gray water tank to about 633600m 3 / year, the amount of fresh water replenishment is about 792000m 3 / year. The long-term operation of gray water under high-hardness and high-alkali conditions has caused serious deposits and fouling in key parts of the system such as lock bucket flushing water pipelines, chilled water pipelines, scrubber trays, and waste water heat exchangers, seriously affecting the long-term cycle of the coal gasification system Continuous and stable operation makes the company bear huge economic and environmental pressure. Aiming at the problems encountered in the above-mentioned production, adopting the processing method of reducing hardness, saving water and reducing pollution in the coal gasification system of the present invention, the gray wate...

Embodiment 3

[0027] For the coal gasification system of a chemical plant, the working condition of black gray water is: Ca in gray water 2+ About 400mg / L, HCO 3 - About 7mmol / L; the system discharges gray water from the gray water tank to about 554400m 3 / year, the amount of fresh water replenishment is about 673200m 3 / year. The long-term operation of gray water under high-hardness and high-alkali conditions has caused serious deposits and fouling in key parts of the system such as lock bucket flushing water pipelines, chilled water pipelines, scrubber trays, and waste water heat exchangers, seriously affecting the long-term cycle of the coal gasification system Continuous and stable operation makes the company bear huge economic and environmental pressure. Aiming at the problems encountered in the above-mentioned production, adopting the processing method of reducing hardness, saving water and reducing pollution in the coal gasification system of the present invention, the gray water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com