Compound i and compound ii and their preparation methods and applications

A compound and reaction technology, applied in the field of compound I and compound II and their preparation, can solve problems such as poor therapeutic effect and adverse reactions, and achieve the effect of slowing down growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

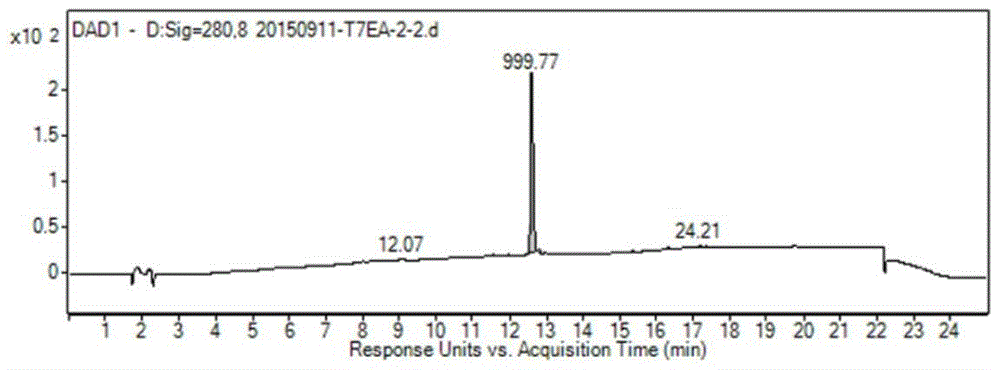

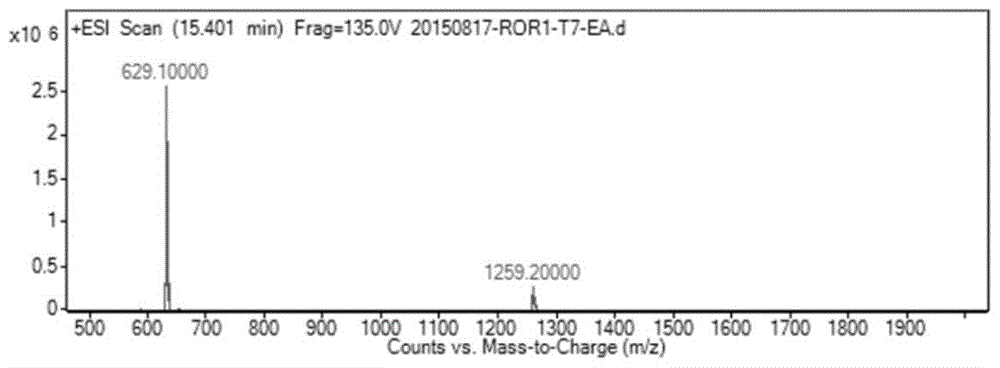

[0048] Weigh 344mg (1mmol) T7 and 341mg (1.125mmol) EA and dissolve in 8mL DMF, add HBTU (427mg, 1.125mmol), triethylamine (416μL, 3mmol) and a catalytic amount of DMAP, and stir the reaction at room temperature for 12 hours. The reaction solution was poured into 100 mL of water, filtered with suction, and the filter residue was washed with water and dried to obtain a crude product. After separation by column chromatography (DCM:MeOH=20:1), 475 mg of T7-EA was obtained as a white solid with a yield of 75.5%. Purity: 95.08%, ESI-MS: m / z=629.1[M+H] + .(Such as Figure 1-2 shown)

preparation Embodiment 2

[0050] Weigh 172mg (0.5mmol) of T7 and 189.4mg (0.625mmol) of EA and dissolve in 6mL of a mixed solvent of benzene and toluene with a volume ratio of 2:1, add HBTU (237.2mg, 0.625mmol), triethylamine (312μL , 2.25mmol) and a catalytic amount of DMAP, stirred at room temperature for 24 hours. The reaction solution was poured into 100 mL of water, filtered with suction, and the filter residue was washed with water and dried to obtain a crude product. After separation by column chromatography (DCM:MeOH=20:1), 236.8 mg of T7-EA was obtained as a white solid, with a yield of 73.2%.

preparation Embodiment 3

[0052] Weigh 516mg (1.5mmol) of T7 and 568.3mg (1.875mmol) of EA and dissolve in 15mL of tetrahydrofuran, add HBTU (711.7mg, 1.875mmol), triethylamine (520μL, 3.75mmol) and a catalytic amount of DMAP, and stir at room temperature React for 18 hours. The reaction solution was poured into 200 mL of water, filtered with suction, and the filter residue was washed with water and dried to obtain a crude product. After separation by column chromatography (DCM:MeOH=20:1), 752 mg of T7-EA was obtained as a white solid, with a yield of 77.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com