Preparation method and application of SnS2-attached textile

A technology of textile and impregnation method, which is applied in the field of materials science, can solve the problems that affect the beauty of textiles and people's emotions, and achieve good self-cleaning effect, enhanced self-cleaning effect, and non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Concrete preparation method of the present invention comprises:

[0028] Step 1: SnCl with a molar mass of 1:2 4 and Na 2 S is dispersed in [Bpy][BF 4 ] In the ionic liquid, in order to ensure uniform dispersion, the mixture needs to be ultrasonically treated for 5-10 minutes;

[0029] Step 2: Add 3×3cm uniform textiles to the above mixture, and ultrasonically treat it for 30-60 minutes;

[0030] Step 3: washing the above silk textiles with deionized water and absolute ethanol for 4 to 6 times, and drying at 60° C. for 2 to 4 hours to obtain the final product.

[0031] N-butylpyridine tetrafluoroborate ionic liquid of the present invention (abbreviated as [Bpy] [BF 4 ]) with a purity of 0.99, purchased from Shanghai Chengjie Chemical Co., Ltd.

[0032] In order to test the attached SnS prepared by the method of the present invention 2 To study the photodegradation effect of textiles under ultraviolet light irradiation, the photocatalytic degradation test was carri...

Embodiment 1

[0035] Step 1: Add 0.01molSnCl 4 and 0.02molNa 2 S was dispersed in 20 mL of [Bpy][BF with a purity of 0.99 4 ] In the ionic liquid, in order to ensure uniform dispersion, the mixture needs to be ultrasonically treated for 5-10 minutes.

[0036] Step 2: Add 3×3 cm silk textiles evenly dipped in red wine to the above mixture, and ultrasonically treat it for 60 minutes.

[0037] Step 3: washing the above silk textiles with deionized water and absolute ethanol for 4 to 6 times, and drying at 60° C. for 2 to 4 hours to obtain the final product.

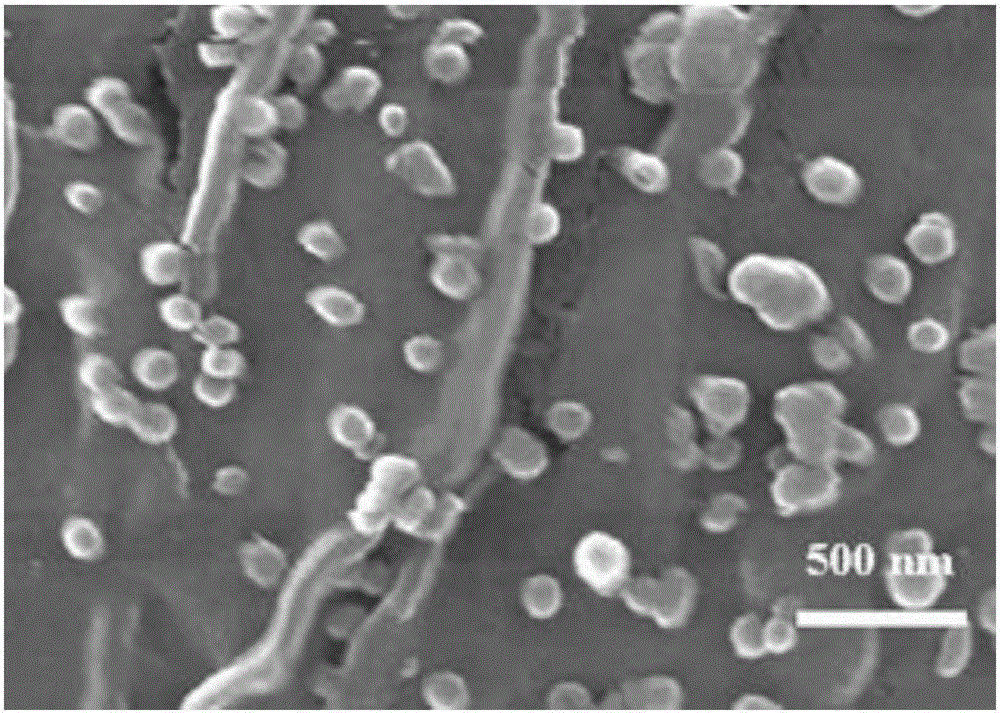

[0038] Self-cleaning SnS prepared as above 2 Silk textile SEM such as figure 1 As shown, it can be seen from the figure that the SnS on silk textiles 2 The particles are extremely fine and clear in shape, well separated and evenly attached to the fibers. SnS 2 The particle size of the particles is 4nm-24nm.

[0039] In order to test the attached SnS prepared in this example 2 To study the photodegradation effect of silk textiles ...

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is that the solvent of this embodiment is deionized water.

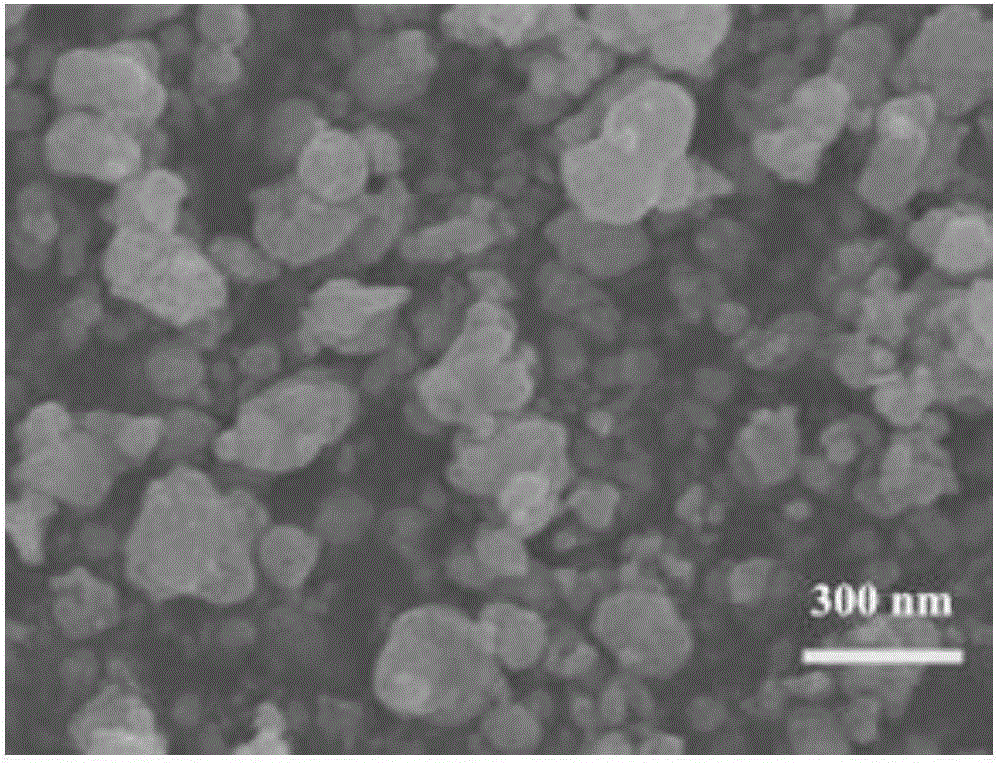

[0043] The self-cleaning SnS prepared in this example 2 Silk textile SEM such as figure 2 As shown, it can be seen from the figure that when no ionic liquid is used as a solvent, SnS 2 Particle agglomeration is serious.

[0044] In order to test the attached SnS prepared in this example 2 To study the photodegradation effect of silk textiles under ultraviolet light irradiation, the photocatalytic degradation test was carried out. After 30 minutes of ultraviolet irradiation, the colorimetric result was grade 7. show [Bpy][BF 4 ] Ionic liquid is the preparation of SnS 2 The best solvent for silk textiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com