an attached sns 2 Preparation method of non-woven fabric and its application

A non-woven, dipping technology, applied in the field of materials science, can solve the problems of particle agglomeration, inability to generate, poor non-woven photolysis reaction, etc., to achieve good stability, low toxicity, and enhanced self-cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Add 0.01mol SnCl 4 and 0.02mol Na 2 S was dispersed in 20 mL of [3-MBP][BF with a purity of 0.99 4 ] In the ionic liquid, in order to ensure uniform dispersion, the mixture needs to be ultrasonically treated for 5-10 minutes;

[0034] Step 2: Add 3×3cm uniform non-woven fabric to the above mixture, ultrasonic treatment for 60 minutes, ultrasonic power is 300W;

[0035] Step 3: The above-mentioned non-woven fabric is washed 4-6 times with deionized water and absolute ethanol, and dried at 60° C. for 2-4 hours to obtain the final product.

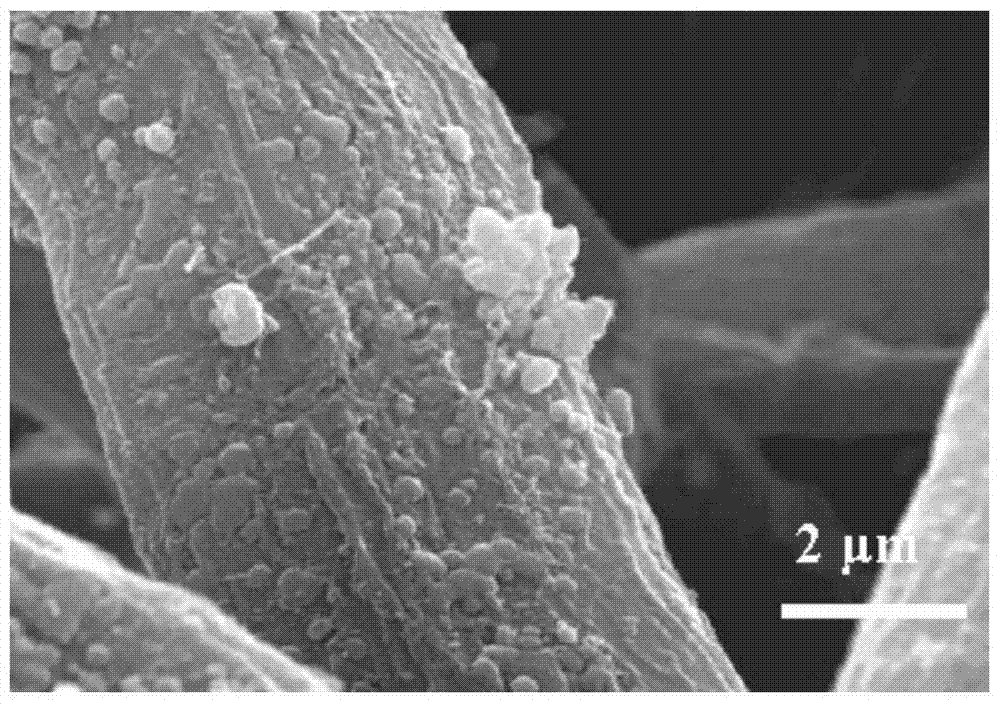

[0036] Attached SnS prepared as above 2 Non-woven SEM such as figure 1 As shown, it can be seen from the figure that the SnS on the non-woven fabric 2 The particles are extremely fine and clear in shape, well separated and evenly attached to the fiber, SnS 2 The particle size of the particles is 30nm-50nm.

[0037] In order to test the attached SnS prepared in this example 2 For the self-cleaning effect of non-woven fabri...

Embodiment 2

[0040] The difference between this example and Example 1 is that the ionic liquid is 1-ethyl-3-methylimidazolium hexafluorophosphate ionic liquid with a purity of 0.99.

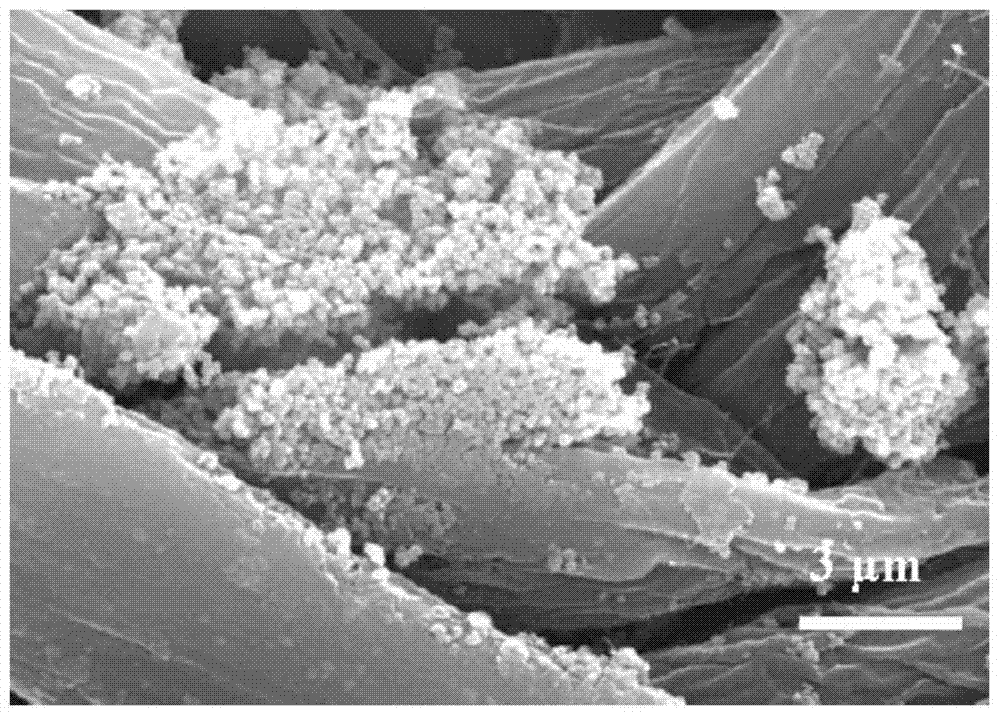

[0041] Attached SnS prepared as above 2 Non-woven SEM such as figure 2 As shown, it can be seen from the figure that the SnS on the non-woven fabric 2 The distribution of particles is uneven, and most of them are concentrated in a certain position on the non-woven fabric, appearing in a pile, and the particle agglomeration phenomenon is serious.

[0042] In order to test the attached SnS prepared in this example 2 For the self-cleaning effect of non-woven fabrics after dipping in red wine, SnS will be attached 2 The non-woven fabric is tested according to the photocatalytic degradation test method.

[0043] The result is: after 30 minutes of ultraviolet irradiation, the colorimetric result is grade 6, and the self-cleaning effect is not good.

Embodiment 3

[0045] The difference between this embodiment and the first embodiment is that the solvent of this embodiment is deionized water.

[0046] In order to test the attached SnS prepared by the method of the present invention 2 The self-cleaning effect of non-woven fabrics on red wine after dipping, will be attached to SnS 2 The non-woven fabric is tested according to the photocatalytic degradation test method.

[0047] The result is: after 30 minutes of ultraviolet irradiation, the colorimetric result is grade 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com