Ultra-light flexible crystalline silicon solar cell module and preparation method thereof

A technology of solar cell components and solar cells, which is applied in the field of solar cells, can solve problems such as inability to bend, component failure, and incapability of large-scale industrialization, and achieve the effects of reducing the use of adhesive materials, reducing the weight of components, and avoiding cracks in cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

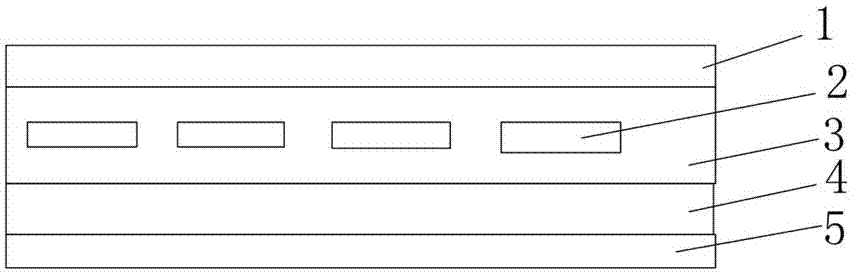

[0030] An ultra-light and flexible crystalline silicon solar cell module, such as figure 1 As shown, including front film 1, solar cell 2, support material 4, encapsulation glue 3 and back film 5, front film 1, solar cell 2, support material 4, encapsulation glue 3 and back film 5 according to front film 1, encapsulation glue 3. The solar cell 2, encapsulant 3, support material 4 and rear film 5 are arranged in sequence and subjected to vacuum hot pressing to form an ultra-light flexible crystalline silicon solar cell module.

[0031] In this embodiment, the encapsulation adhesive 3 is a hot melt adhesive with a surface density of 30g / m 2 .

[0032] In this embodiment, the hot melt adhesive 3 is polyolefin with a thickness of 60 μm.

[0033] In this embodiment, the back film 5 is a 25 μm white PET film.

[0034] In this embodiment, the front film 1 is a corona-treated ETFE film with a thickness of 25 μm.

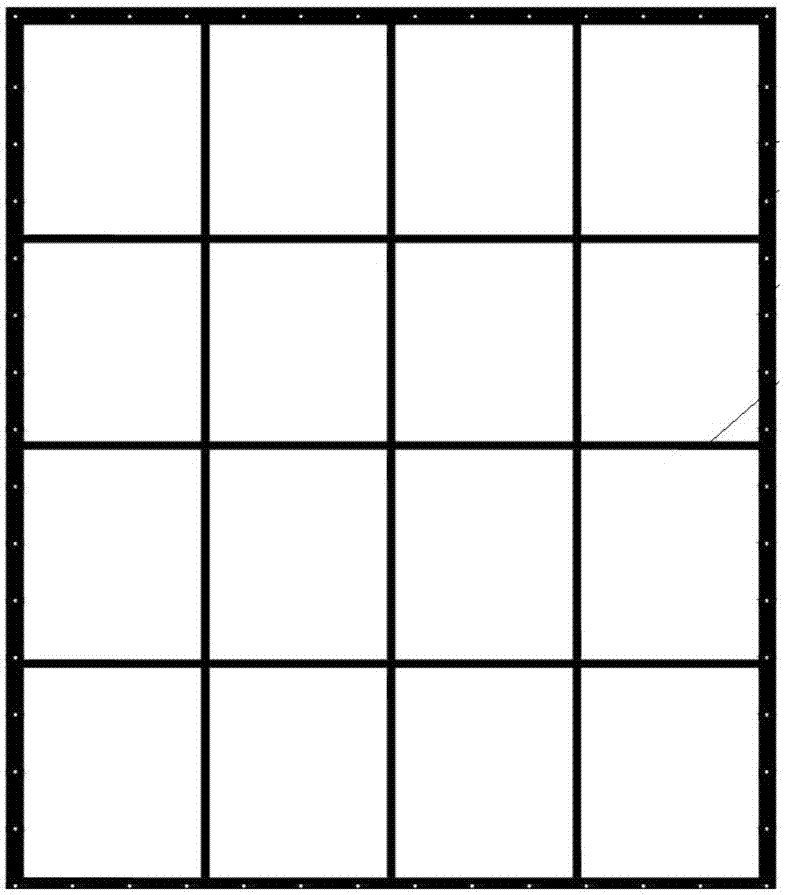

[0035] In this embodiment, the support material 4 is a grid-shaped ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com