Pole piece surface treatment method, pole piece surface treatment device and piece manufacturing machine with pole piece surface treatment device

A surface treatment device and surface treatment technology, applied in battery electrodes, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as short circuit, production efficiency reduction, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

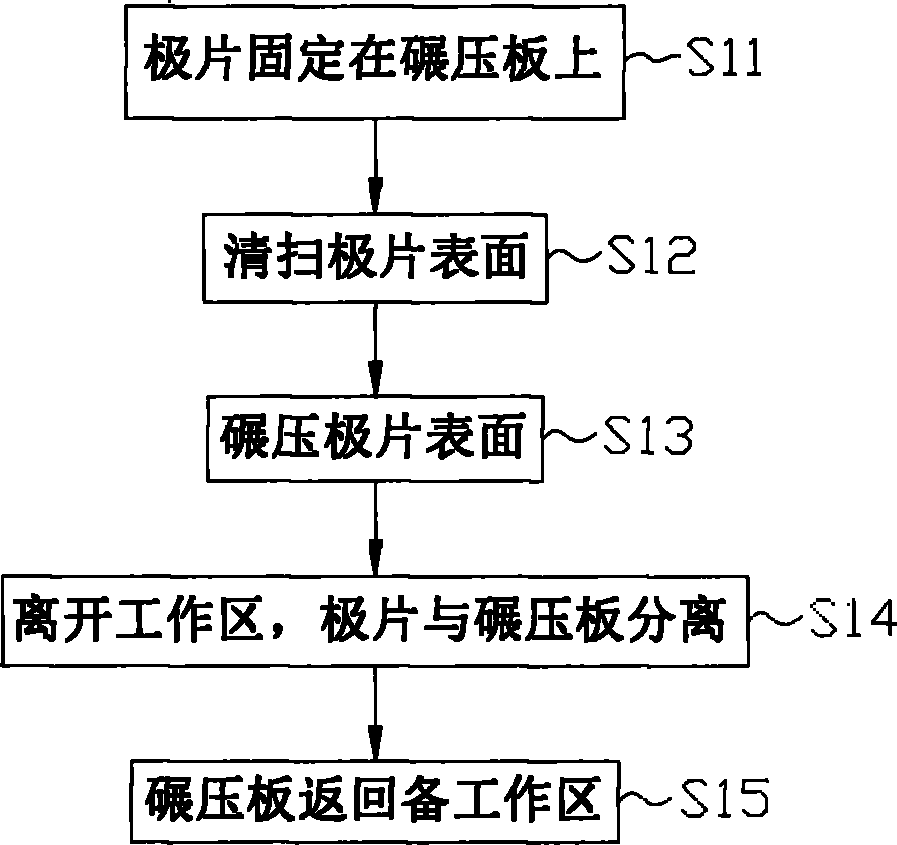

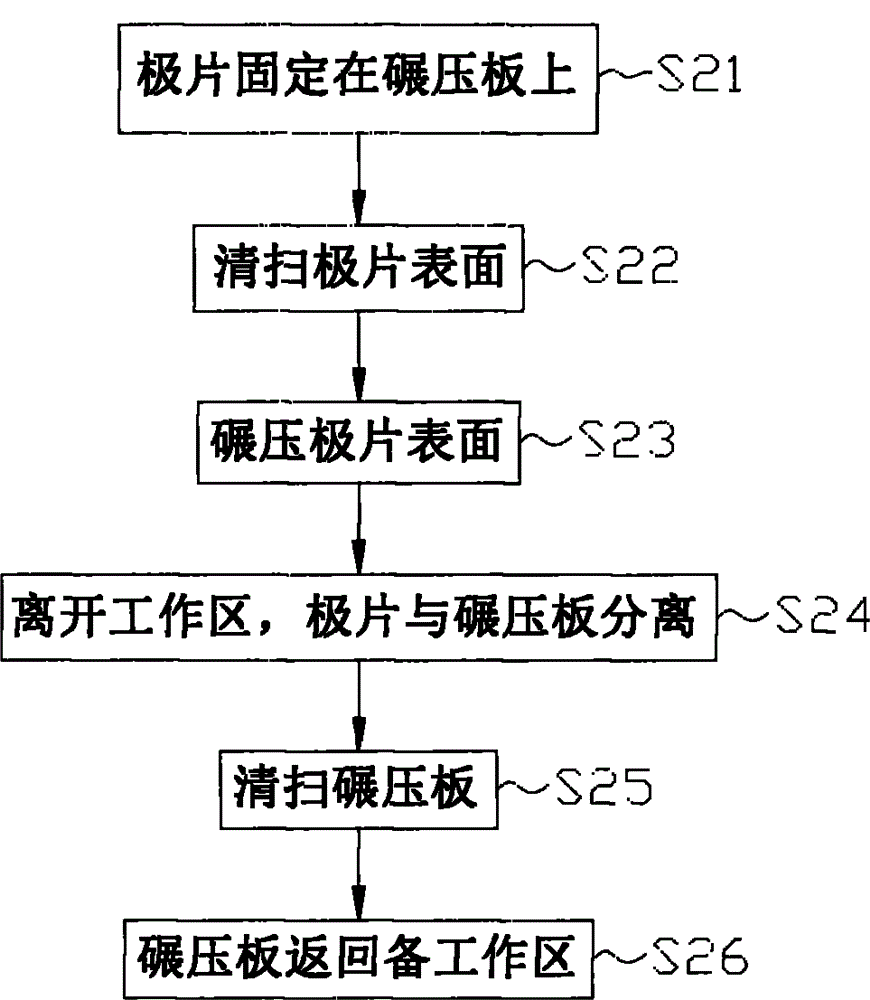

Method used

Image

Examples

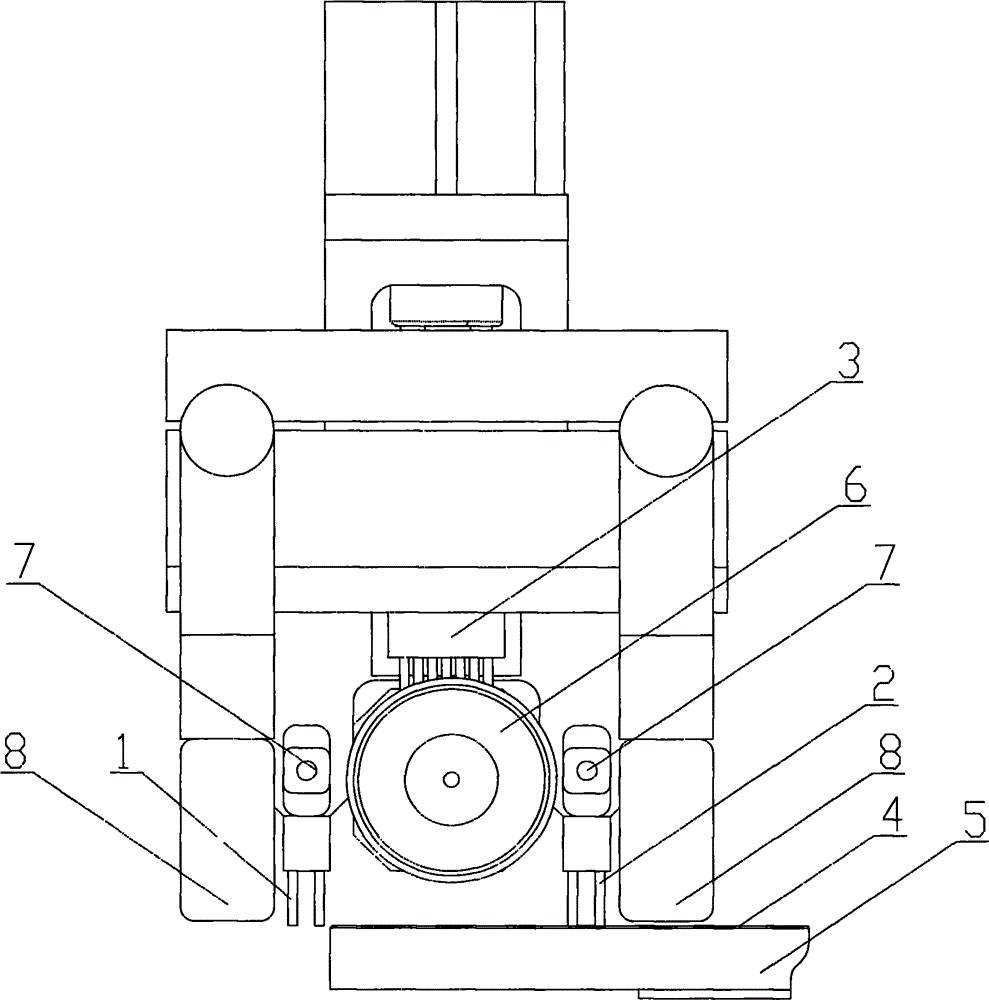

Embodiment Construction

[0031] The core of the present invention is to provide a method for treating the surface of the pole piece, which can reduce the height of burrs, reduce the amount of dust on the surface of the pole piece, improve the surface quality of the pole piece, and ensure that the diaphragm will not be punctured when the pole piece is used to produce batteries. Another core of the present invention is to provide a pole piece surface treatment device and a tablet making machine including the above processing device. The pole pieces produced by the tablet making machine are of high quality and good quality.

[0032] The inside and outside involved in this article are defined based on the working area of the clean pole piece. The space where the center of the work area is located is the inside, and the space away from the space is outside; The direction of motion is defined on the basis, the position where the pole piece passes first is the front, and the position where the pole piece pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com