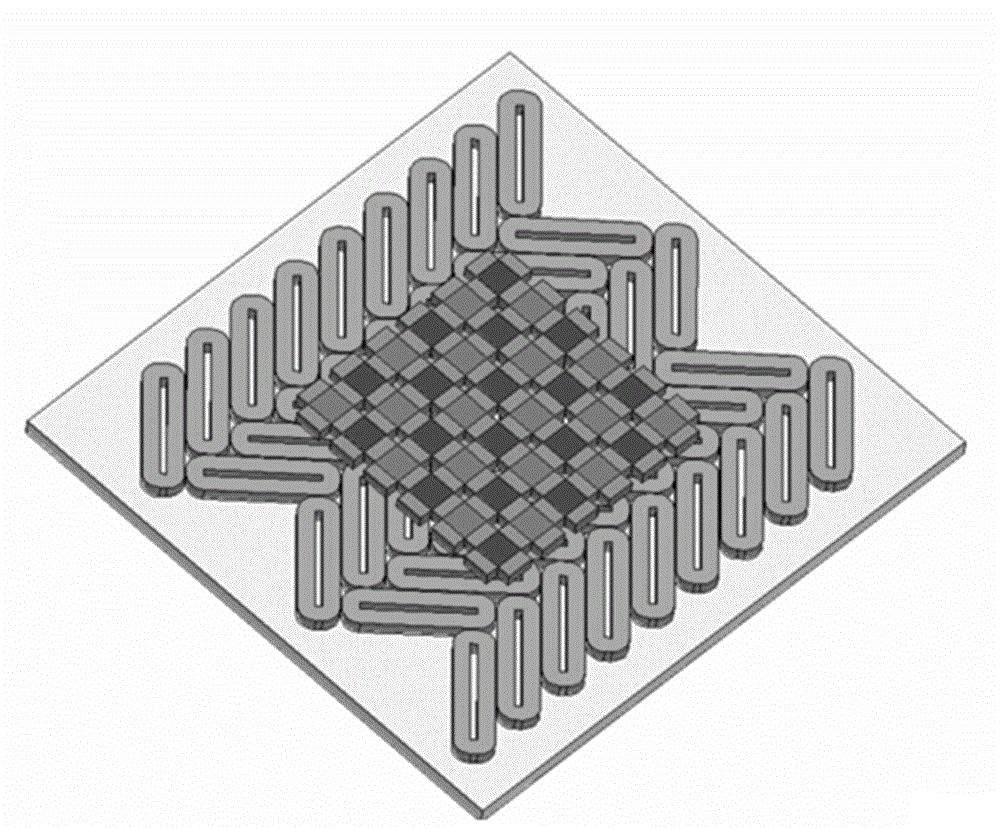

Method for improving control accuracy of coil current driver of magnetic suspension planar motor

A planar motor and coil current technology, applied in the direction of magnetic attraction or thrust holding device, electrical components, etc., can solve problems such as difficult to find servo gain, unable to effectively reduce the internal temperature of the coil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

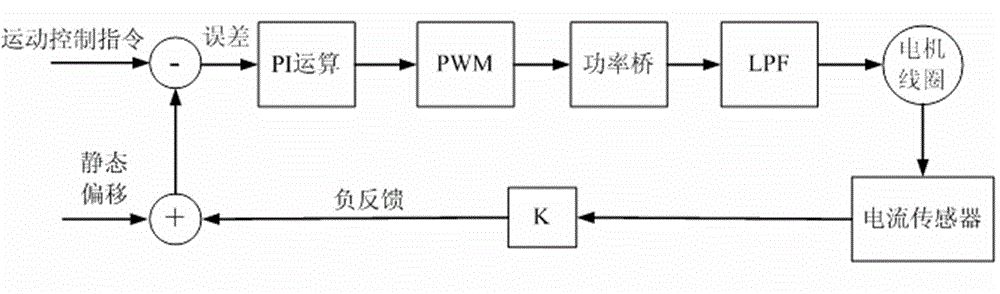

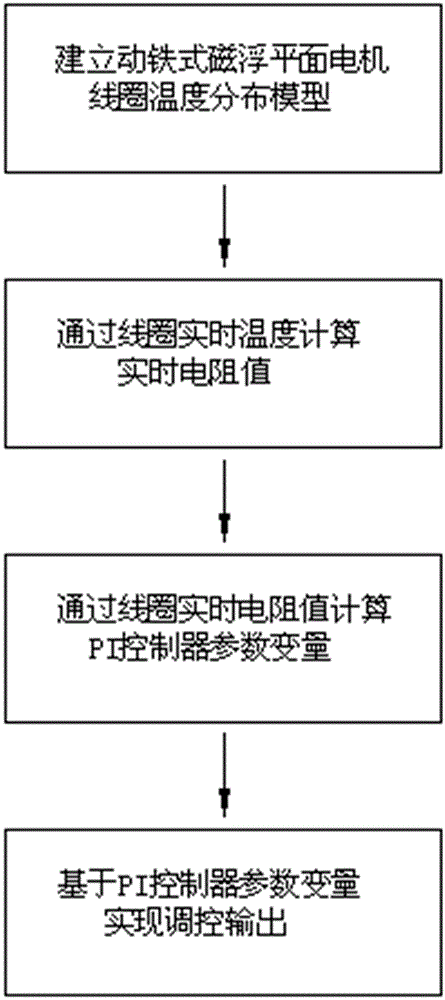

[0024] Such as figure 1 The present invention shows a method for improving the control accuracy of the coil current driver of the maglev planar motor. According to the temperature distribution model of the maglev planar motor coil in the working process, a real-time adjustment of control parameters is provided for the moving iron type maglev planar motor coil current driver, including the following step:

[0025] a. According to the temperature distribution model of each coil of the moving iron maglev planar motor line during the working process, use the formula

[0026] T n , m t = T n , m t - Δt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com