Sand-covered casting device and casting process for iron mold of brake disc friction ring for high-speed railway

A sand-covered iron mold and casting process technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of poor surface quality of brake discs, slag inclusions on the upper surface, and high production costs, so as to meet market demand, Effect of small amount of turning and improvement of friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

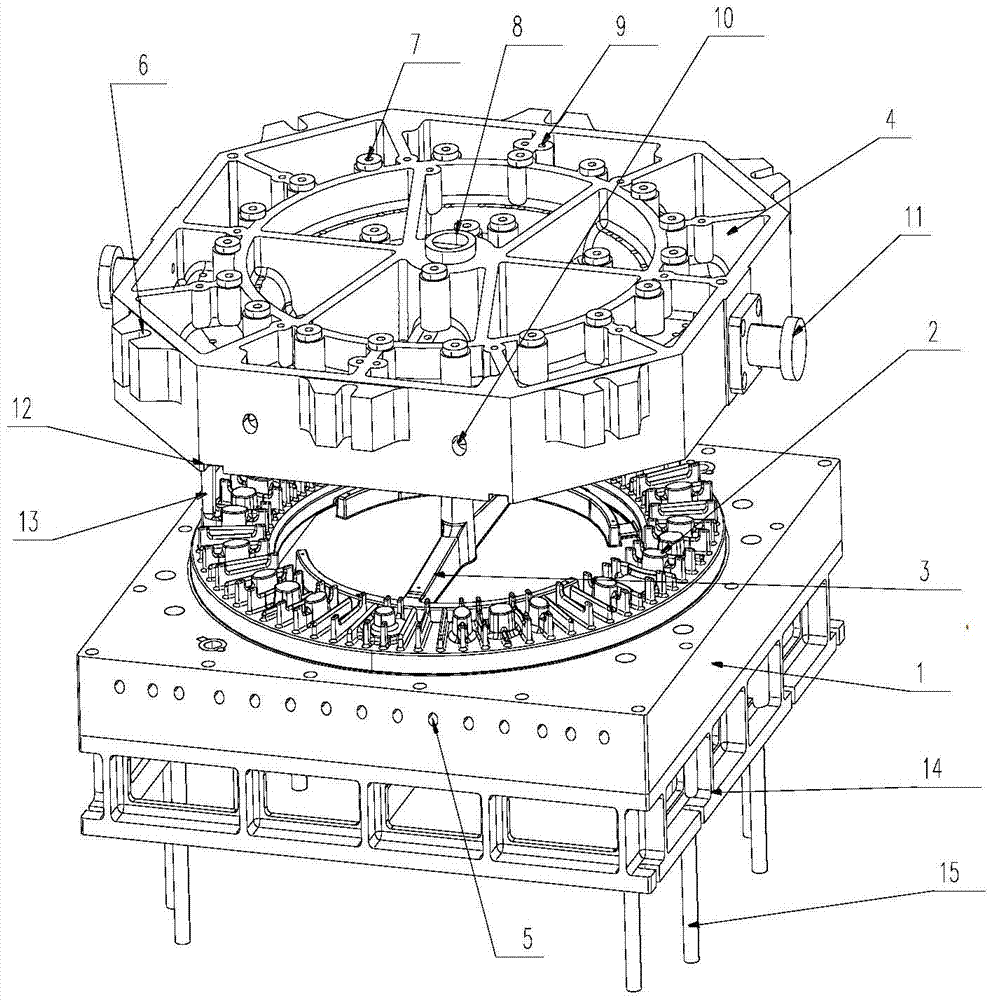

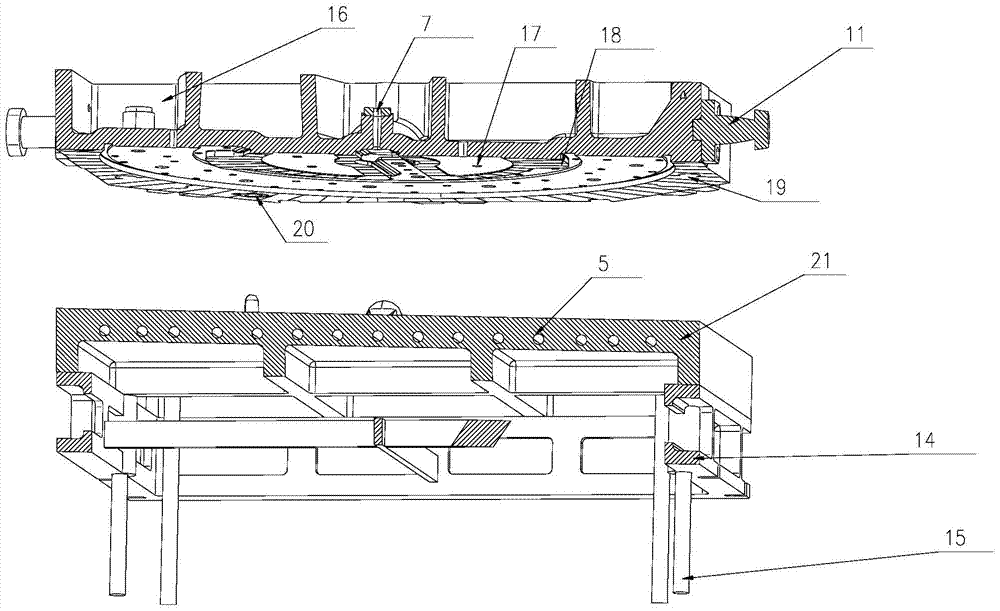

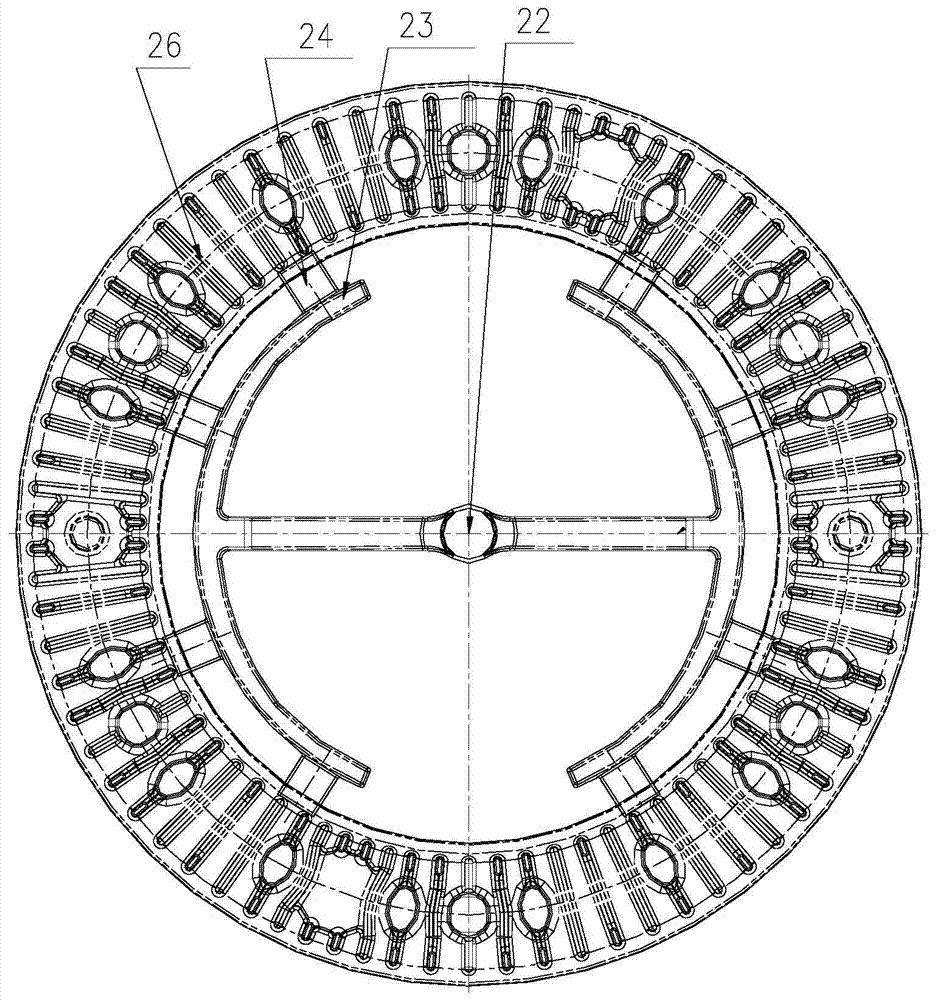

[0056] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0057] An iron mold sand-covered casting device for brake disc friction rings for high-speed rail, including an upper mold molding device and a lower mold molding device. The casting device works in the state where the temperature gradient of cold and hot changes greatly for a long time, which is prone to defects such as deformation and cracks, and even leads to scrapping. The arrangement structure of the sand box box ribs is as follows: the sand box is made of QT500-7 material, with a uniform wall thickness of 30mm to avoid thick and large heat storage areas. The inner stress of the sand box with this structure is small, the deformation is small, and the temperature field is evenly distributed. . The cast sand box should be subjected to area stress treatment, after rough machining, it must be subjected to failure treatment or vibration area stress tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com