Processing technology of integrated cylinder of gas-liquid separator

A gas-liquid separator and processing technology, applied in refrigeration and liquefaction, lighting and heating equipment, refrigeration components, etc., can solve problems such as failure to meet strength requirements, cumbersome processes, energy waste, etc., and achieve accurate molding and operation. Simple and convenient, the effect of reducing the amount of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

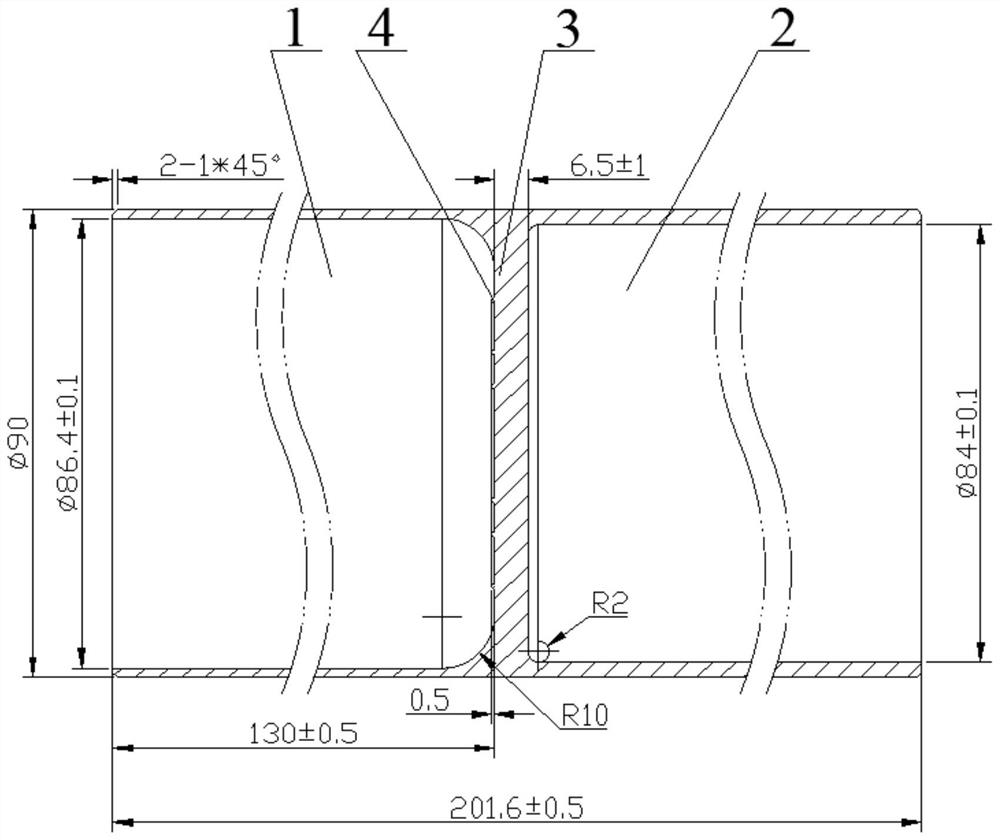

[0034] The present invention is further described below in conjunction with embodiment: as figure 1 as shown,

[0035] A processing technology for an integrated cylinder body of a gas-liquid separator, comprising the following steps:

[0036] Step 1. The aluminum alloy profile is cut into a fixed length by a blanking saw for later use; one end of the aluminum alloy profile is a low-voltage end, and the other end is a high-voltage end. The diameter of the aluminum alloy profile is 90 mm, and the length is 201.6 ± 0.5 mm; The model of the alloy profile is 6061;

[0037] Step 2. Carry out lathe positioning on the low-voltage end of the aluminum alloy profile through the CNC lathe;

[0038] Step 3. Carry out lathe positioning on the high-voltage end of the aluminum alloy profile through the CNC lathe;

[0039] Step 4. Clean the aluminum alloy profiles that have been nested at both ends;

[0040] Step 5. The cleaned aluminum alloy profile is subjected to surface pore treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com