Waste treatment device for laser cutting

A technology of waste treatment and laser cutting, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of burning the lens, damaging the optical system, and affecting the processing quality of the workpiece, so as to improve the processing quality and precision and protect the optics. The effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification. The "up" and "down" referred to in this embodiment are consistent with the up and down directions of the drawings themselves; the white hollow arrows in the drawings represent the direction of waste material flow.

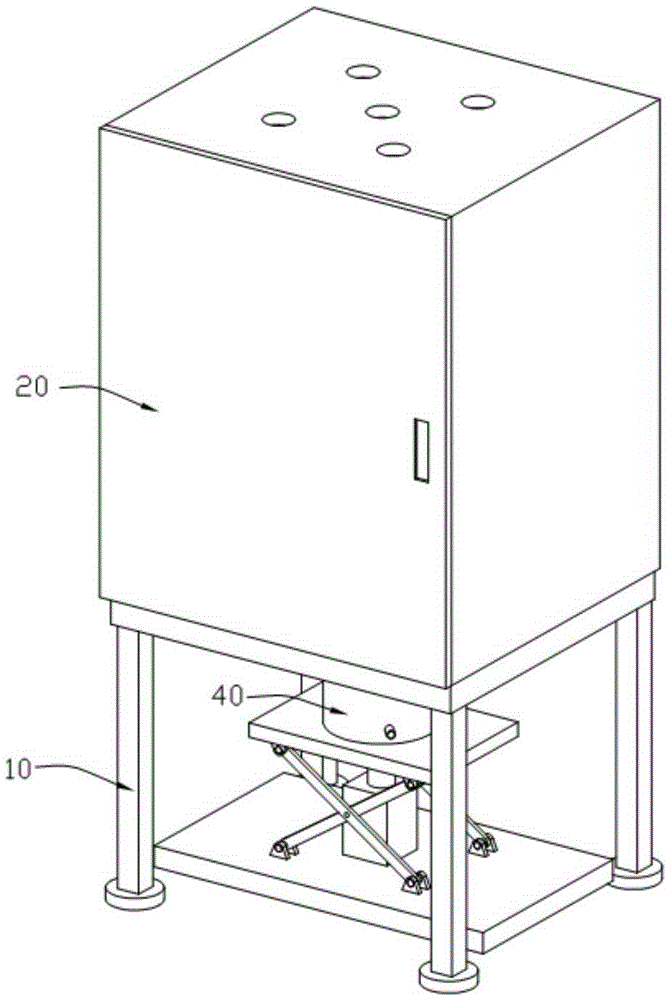

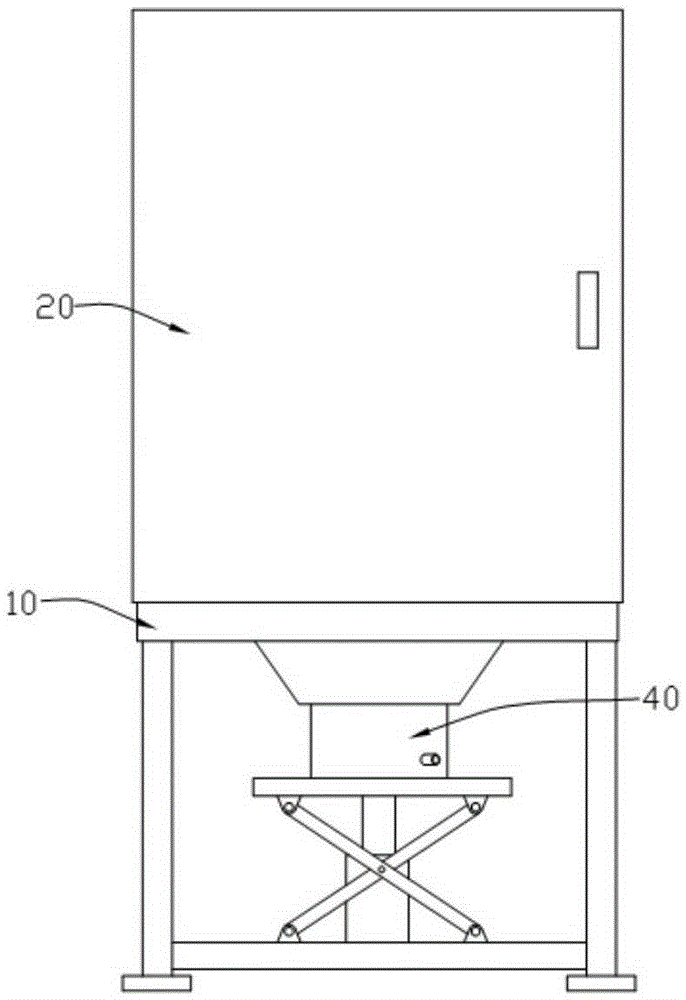

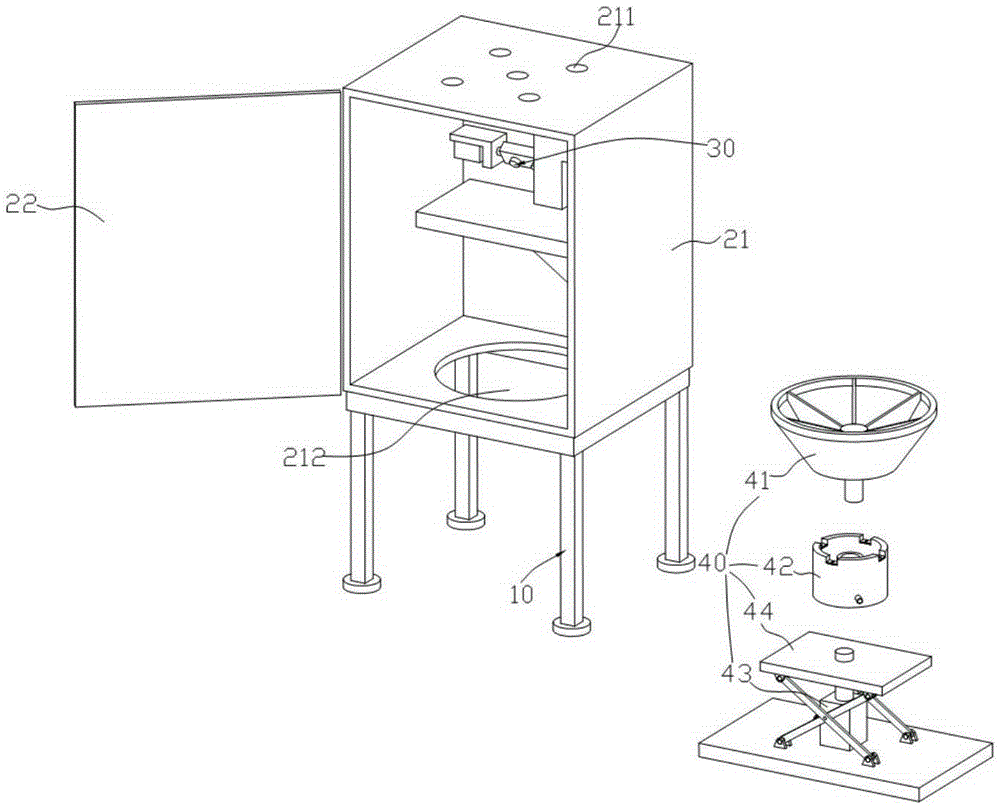

[0025] See Figure 1 to Figure 4 As shown, a laser-cut waste material processing device includes: a support frame 10; a casing 20 installed on the support frame 10, which includes a main casing 21, hinged on the main casing 21 and connected to the main casing 21. The main housing 21 is jointly surrounded by a protective door 22 forming an airtight chamber, a workbench 23 and a laser 24 installed in the main housing 21, and the workbench 23 is located in the middle of the main housing 21. The laser 24 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com