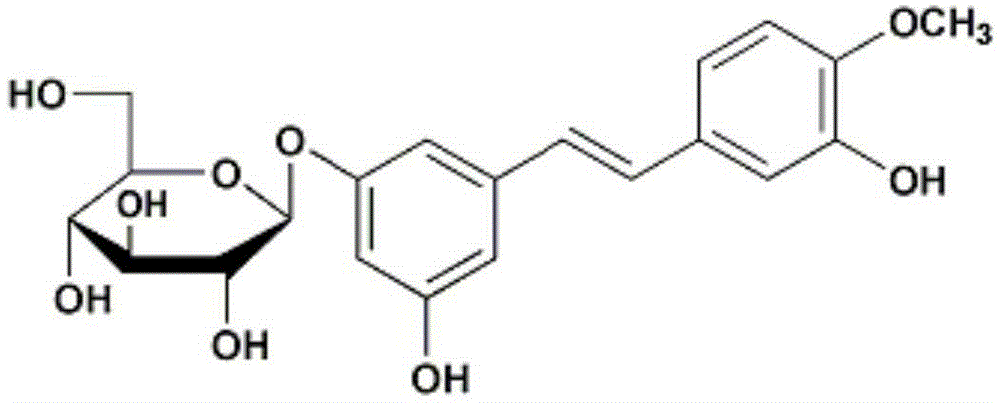

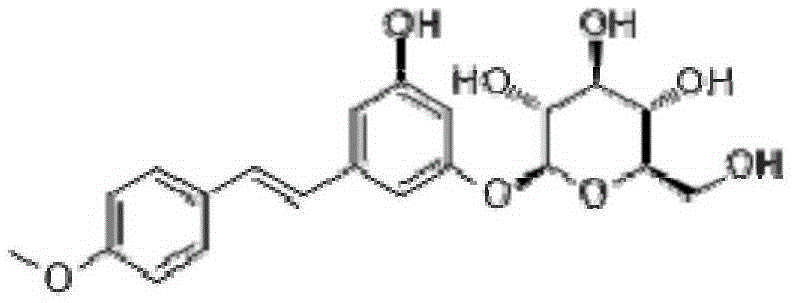

Industrial production technology for separating rhaponiticin and deoxidized rhaponiticin simultaneously

A technology of deoxyreveredin and rhubarb, which is applied in the field of medicine, can solve the problems of not being able to meet the needs of new drug research and production, not getting deoxyreverin, and prone to safety accidents, so as to ensure health and safety, The effect of low cost and non-toxic solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

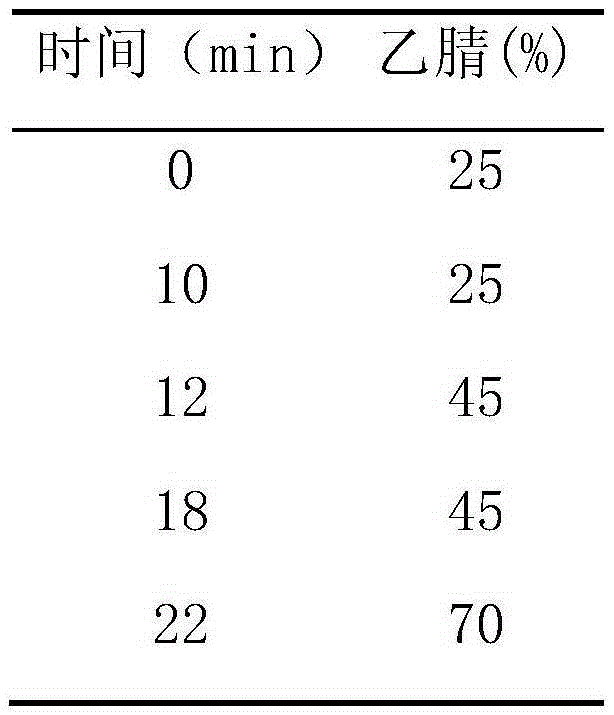

Embodiment 1

[0070] Crush 200 kg of Hetao rhubarb into 40 meshes, add 1,600 kg of 75% alcohol, stir and extract at room temperature for 2 hours, extract once more according to the above method, combine the extracts, concentrate under reduced pressure below 60°C until alcohol-free, add 1,000 kg of water And filtered, adsorbed on the treated polyamide chromatography column, washed with water to remove large polar impurities, then eluted with 30% alcohol for twice the column volume, and then eluted with 50% alcohol until the target molecule was completely eluted, First collect the eluate of ethanol, then collect the eluate of deoxyreveridin, concentrate under reduced pressure below 60°C until just crystallization, cool to room temperature and separate by centrifuge, dry in a hot air oven below 50°C, 15.6 kg of crude product of rhubarb was obtained, with a content of 94.8%, and 3.1 kg of crude product of deoxyrhein, with a content of 96.2%. Put the two kinds of crude products into the reaction...

Embodiment 2

[0072] Crush 200 kg of rhubarb into 80 meshes, add 1800 kg of 60% alcohol, stir and reflux for extraction for 1.5 hours, extract once more according to the above method, combine the extracts, concentrate under reduced pressure below 60°C until there is no alcohol smell, add 1000 kg of water And filtered, adsorbed on the treated polyamide chromatography column, washed with water to remove large polar impurities, then eluted with 20% alcohol for three times the column volume, and then eluted with 60% alcohol until the target molecule was completely eluted, First collect the eluate of ethanol, then collect the eluate of deoxyreveridin, concentrate under reduced pressure below 60°C until just crystallization, cool to room temperature and separate by centrifuge, dry in a hot air oven below 50°C, 14.8 kg of the crude product of rhubarb was obtained, with a content of 95.2%, and 3.8 kg of crude product of deoxyrhubarb, with a content of 95.8%. Put the two crude products into the reac...

Embodiment 3

[0074] Crush 200 kg of Rhubarb Rhubarb into 60 meshes, add 2000 kg of 50% alcohol, stir and reflux for extraction for 1 hour, extract once more according to the above method, combine the extracts, concentrate under reduced pressure below 60°C until alcohol-free, add 1000 kg of water and filtered, adsorbed on the treated polyamide chromatography column, washed with water to remove large polar impurities, then eluted with 40% alcohol for 1.5 times the column volume, and then eluted with 55% alcohol until the target molecule was completely eluted Next, first collect the eluate of ethanol, then collect the eluate of deoxyreverin, respectively concentrate under reduced pressure below 60°C until just crystallization, cool to room temperature and centrifuge to separate, store in a hot air oven below 50°C After drying, 15.3 kg of the crude product of rhubarb was obtained, with a content of 94.1%, and 6.3 kg of crude product of deoxyrhein, with a content of 96.6%. Put the two kinds of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com