A kind of oil-resistant flame-retardant rubber shoe material

A technology for flame retardant rubber and shoe materials, applied in the field of rubber shoe materials, can solve the problems of complex preparation process and lack of flame retardant performance, and achieve the effects of reducing production cost, excellent anti-scorch effect, and preventing early vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

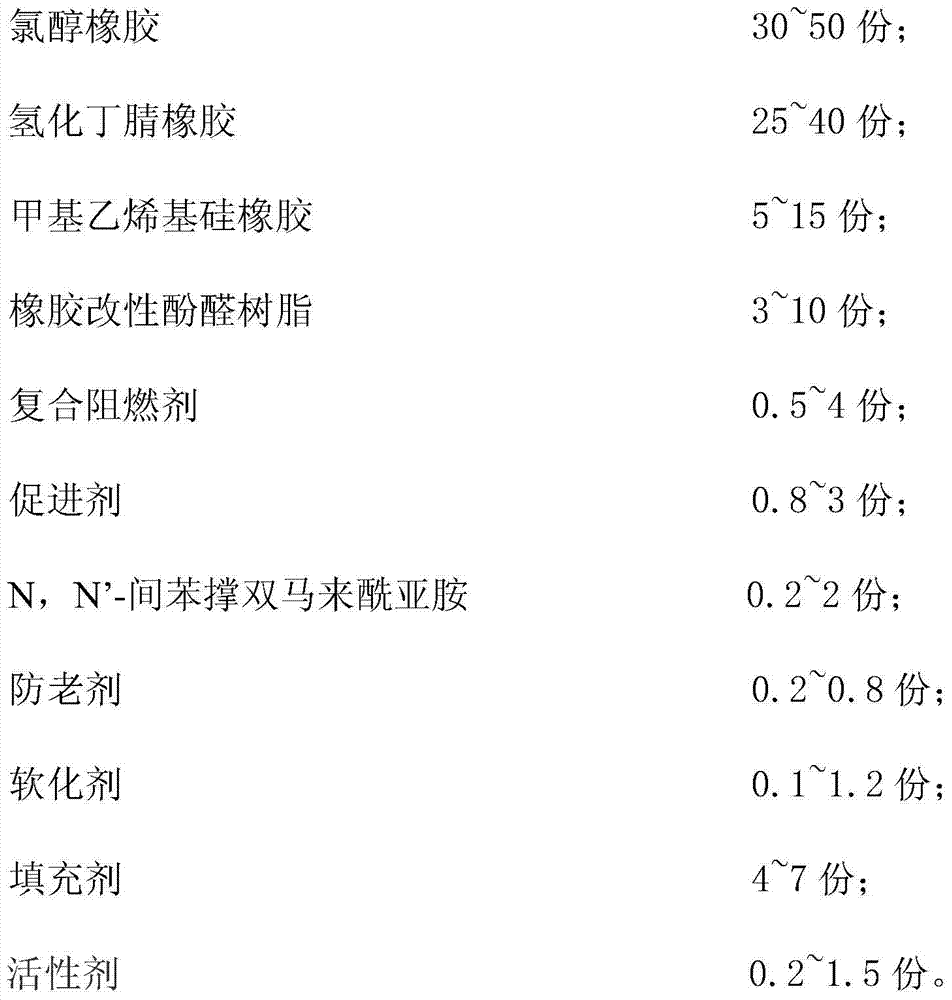

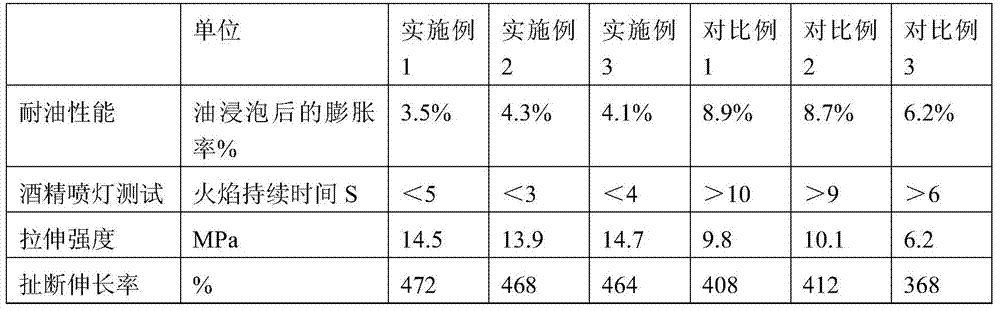

[0023] An oil-resistant and flame-retardant rubber shoe material, comprising the following components in parts by weight: 30 parts of chlorohydrin rubber; 25 parts of hydrogenated nitrile rubber; 5 parts of methyl vinyl silicone rubber; 3 parts of rubber-modified phenolic resin; 0.5 parts of accelerator; 0.8 parts of accelerator; 0.2 parts of N, N'-m-phenylene bismaleimide; 0.2 parts of anti-aging agent; 0.1 parts of softener; 4 parts of filler; 0.2 parts of active agent.

[0024] The composite flame retardant is crystalline type II ammonium polyphosphate, magnesium hydroxide and chlorinated paraffin in a weight ratio of 1:1:3.

Embodiment 2

[0026] An oil-resistant and flame-retardant rubber shoe material, comprising the following components in parts by weight: 40 parts of chlorohydrin rubber; 35 parts of hydrogenated nitrile rubber; 10 parts of methyl vinyl silicone rubber; 7 parts of rubber-modified phenolic resin; 2 parts of accelerator; 2 parts of accelerator; 1 part of N, N'-m-phenylene bismaleimide; 0.5 part of anti-aging agent; 1 part of softener; 5 parts of filler; 0.5 part of active agent.

[0027] The composite flame retardant is crystalline type II ammonium polyphosphate, magnesium hydroxide and chlorinated paraffin in a weight ratio of 1:1:3.

Embodiment 3

[0029] An oil-resistant and flame-retardant rubber shoe material, comprising the following components in parts by weight: 50 parts of chlorohydrin rubber; 40 parts of hydrogenated nitrile rubber; 15 parts of methyl vinyl silicone rubber; 10 parts of rubber modified phenolic resin; 4 parts of agent; 0.8-3 parts of accelerator; 2 parts of N, N'-m-phenylene bismaleimide; 0.8 parts of anti-aging agent; 1.2 parts of softener; 7 parts of filler; 1.5 parts of active agent.

[0030] The composite flame retardant is crystalline type II ammonium polyphosphate, magnesium hydroxide and chlorinated paraffin in a weight ratio of 1:1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com