A kind of mg-zn-gd quasicrystal-reinforced az91 magnesium alloy and its preparation method

An AZ91 and magnesium alloy technology, applied in the field of AZ91 alloy and its preparation, can solve the problems of poor corrosion, low mechanical properties, coarse grains, etc., to increase the number of grains, elongation and corrosion resistance, crystal The effect of particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

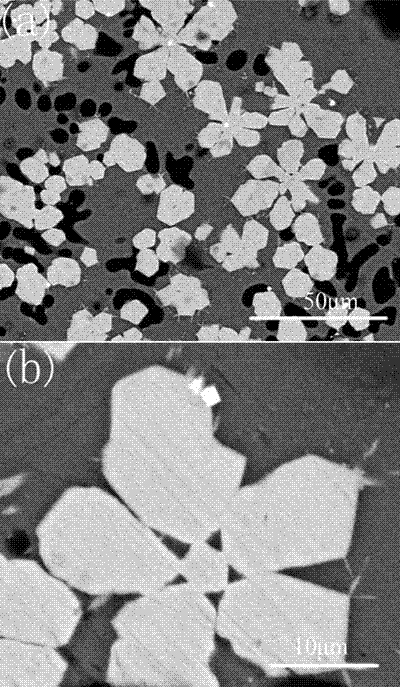

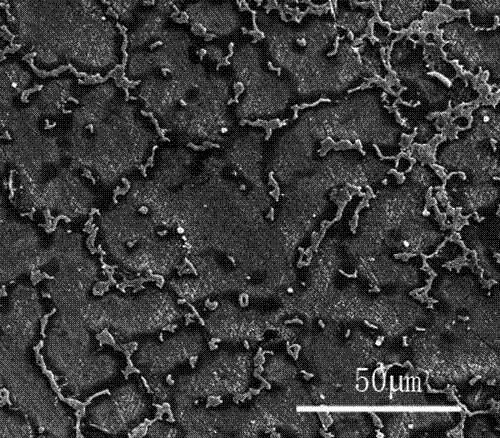

[0030] A Mg-Zn-Gd quasicrystalline phase reinforced AZ91 magnesium alloy is characterized in that it has the following mass percentages: Al8.82, Zn 1.90%, Gd 0.29%, and the balance is Mg.

[0031] Take the following steps to make:

[0032] 1) Preparation of Mg-Zn-Gd quasicrystalline master alloy:

[0033] Prepare magnesium ingots, zinc ingots and Mg-Gd intermediate alloys according to the ratio as raw materials, raise the furnace temperature to 680°C, put the magnesium ingots into the graphite crucible, and then put the graphite crucible into the SF 6 -CO 2 In the resistance furnace of mixed gas, add Mg-Gd intermediate alloy after the magnesium ingot is melted, and finally add zinc ingot after the Mg-Gd intermediate alloy is melted, keep warm for 15 minutes after the zinc is melted, then slowly shake the graphite crucible for 1 minute, and put it into the furnace Stand still for 2 minutes, pour into metal molds to obtain Mg-Zn-Gd quasicrystalline alloy with uniform compositi...

Embodiment 2

[0040] A Mg-Zn-Gd quasicrystalline phase reinforced AZ91 magnesium alloy is characterized in that it has the following mass percentages: Al 8.65%, Zn 2.76%, Gd 0.58%, and the balance is Mg.

[0041] Take the following steps to make:

[0042] 1) Preparation of Mg-Zn-Gd quasicrystalline master alloy:

[0043] Prepare magnesium ingots, zinc ingots and Mg-Gd intermediate alloys according to the ratio as raw materials, raise the furnace temperature to 700°C, put the magnesium ingots into the graphite crucible, and then put the graphite crucible into the SF 6- CO 2 In the mixed gas resistance furnace, after the magnesium ingot is melted, add the Mg-Gd master alloy, and finally add the zinc ingot after the Mg-Gd master alloy is melted. Stand in the middle for 2.25min, and pour it into a metal mold to obtain a Mg-Zn-Gd quasicrystal alloy with uniform composition;

[0044] 2) Preparation of AZ91 magnesium alloy:

[0045] Using 8.82% Al by mass, 0.89% Zn and 90.29% Mg as raw materials...

Embodiment 3

[0050] A Mg-Zn-Gd quasicrystalline phase reinforced AZ91 magnesium alloy is characterized in that it has the following mass percentages: Al 8.49%, Zn 3.59%, Gd 0.86%, and the balance is Mg.

[0051] Take the following steps to make:

[0052] 1) Preparation of Mg-Zn-Gd quasicrystalline master alloy:

[0053] Prepare magnesium ingots, zinc ingots and Mg-Gd intermediate alloys according to the ratio as raw materials, raise the furnace temperature to 720°C, put the magnesium ingots into the graphite crucible, and then put the graphite crucible into the SF 6 -CO 2 In the mixed gas resistance furnace, add Mg-Gd master alloy after the magnesium ingot is melted, and finally add zinc ingot after the Mg-Gd master alloy is melted, keep warm for 20 minutes after the zinc is melted, then slowly shake the graphite crucible for 1.5 minutes, put it into the Stand in the middle for 2.5min, pour into the metal mold, obtain the Mg-Zn-Gd quasicrystal alloy with uniform composition;

[0054] 2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com