Patents

Literature

35results about How to "Increase the number of grains" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

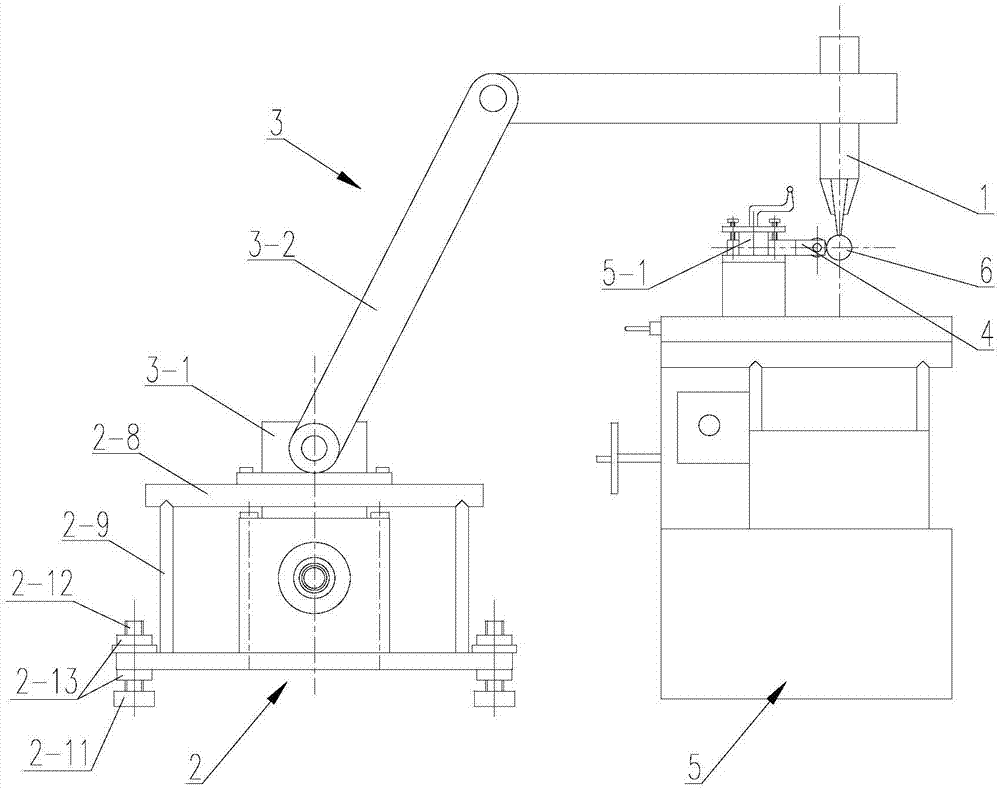

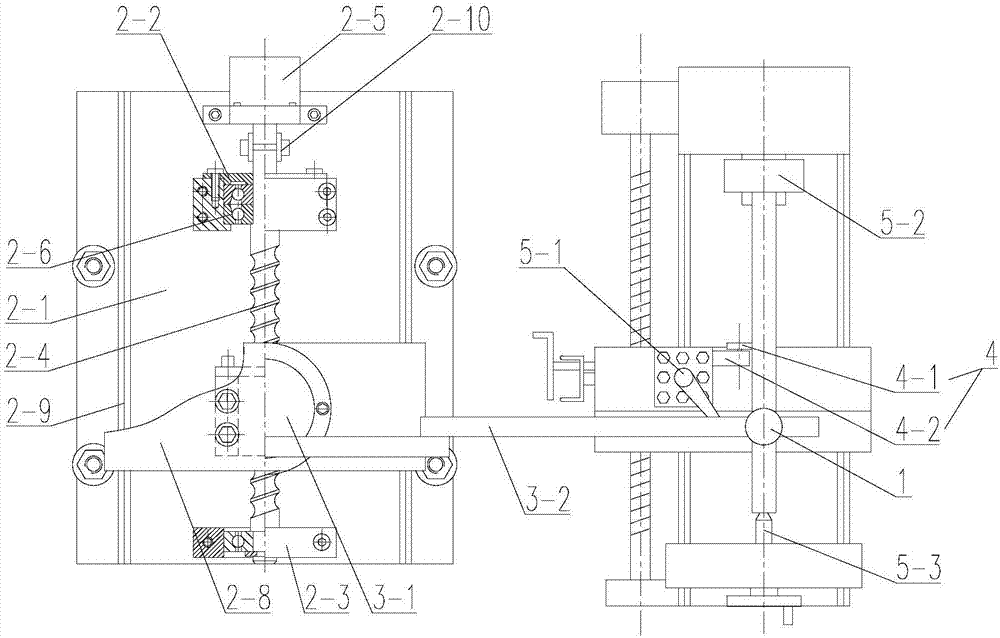

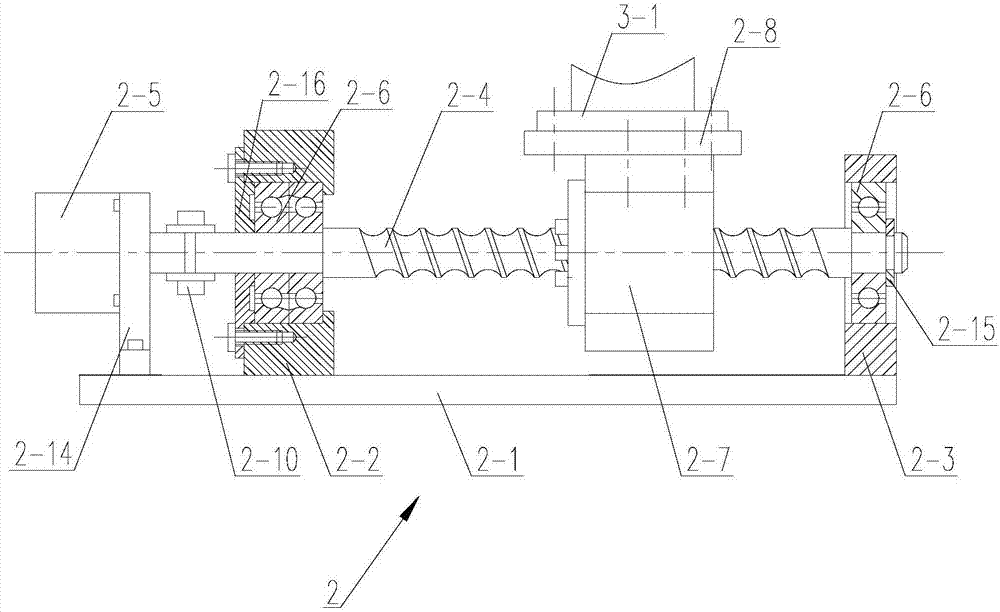

Laser cladding rolling composite machining technology and device

PendingCN107009151AImprove organizationImprove performanceOther manufacturing equipments/toolsMetallic material coating processesLaser processingEngineering

The present invention relates to the technical field of laser processing, in particular to a laser cladding and rolling composite processing technology and device. The cladding head moves along the axial direction of the cladding part to form a cladding layer on the surface of the cladding part. At the same time, the outer circular rolling knife applies a certain pressure to the cladding layer along the radial direction of the cladding part under the action of external force to obtain a modified Cladding layer, the device includes: a laser cladding head, the laser cladding head is used to conduct the laser beam; a robot, the robot includes a sliding system and a manipulator set on the sliding system; Apply radial pressure; the outer circular rolling knife is fixed on the tool holder of the horizontal lathe. During the laser cladding process, the present invention uses a certain pressure introduced radially to improve the structure and performance of the laser cladding layer, and has the advantages of operation Convenience, high production efficiency and environmental protection.

Owner:JIANGSU UNIV OF TECH

Method for producing tungsten bar serving as halogen tungsten lamp tungsten filament

ActiveCN102198507AFine and uniform crystals on the cross-sectionAvoid spikesHalogenAmmonium paratungstate

The invention provides a method for producing a tungsten bar serving as a halogen tungsten lamp tungsten filament, comprising the following steps of: material selecting, pre-reducing, high potassium doping, reducing, acid rinsing, powder preparing, cold static pressure shaping, high temperature sintering and the like. Compared with the conventional technology, the method is characterized in that two crystal ammonium paratungstates are utilized to prepared raw materials, high potassium doping is adopted, preparation of middle granule tungsten powder is added, a powder distribution scheme is optimized by the middle granule tungsten and a unique incipient fusion high temperature sintering process is utilized. In the method, the granularity distribution of the tungsten powder avoids the peak or double peak phenomenon and has good normal distribution, after being sintered at high temperature, the cross section crystal of the tungsten bar is thin and uniform; the tungsten bar is pressed by a powder mixing scheme; according to a forming mechanism of potassium foams, the number of tungsten bar cross section crystal grains is increased; and the partial growth of the crystal grains is avoided so that the potassium foam is small in aperture, large in density, multiple in crystal boundary, long in line and uniform in distribution.

Owner:GANZHOU HONGFEI TUNGSTEN & MOLYBDENUM MATERIALS

Preparation method of wolfram filament for halogen tungsten lamp

InactiveCN101157997AHigh dispersion is beneficialPromote deep processingLamp incadescent bodiesAmmonium paratungstatePotassium

The invention provides a preparation method for high yield rate, good high temperature and anti-deforming performance tungsten filament used by a tungsten lamp. The recrystallization of the invention can form good coattail joint structure, the aspect ratio is greater than 12, the high temperature intension is high in a high temperature ignition status, the high temperature anti-sag performance and anti-deforming performance is good; normal temperature intension in a normal status and ductility is good, which extends the durability of the halogen tungsten lamp; the invention levels up the high temperature anti-sag performance and enwinding performance of the tungsten used by the halogen tungsten lamp. The invention has the key technique of thinning and even dispersion of tungsten wire potassium bubble, taking A3 type ammonium paratungstate as raw material, tungsten powder preparation plan adopting tungsten powder C is different from the existing tungsten powder preparation technique, design vertical melt sintering and middle-high temperature annealing according to the height dispersion and homogenization of apotassium bubble. The invention adopts the novel production techniques such as using corundum tube oven to a first recrystallization annealing.

Owner:GANZHOU HONGFEI TUNGSTEN & MOLYBDENUM MATERIALS

Cultivation method for sun rose grapes

The invention discloses a cultivation method for sun rose grapes. The cultivation method includes the following steps: setting up a flat mesh rack; performing field planting of seedlings of the sun rose grapes; performing pinching and trimming after sprouting of the planting seedlings; continuously performing pinching after sprouting of the grapes in the second year; shaping spica before blooming of the grapes; performing fruit retention after full blooming of the spica of the grapes; setting the spica after fruit bearing; performing particle scattering on clusters after setting the spica; performing harvesting after the grapes are ripe. With the method that the spica are trimmed before blooming of the grapes, fruit is retained after full blooming of the spica of the grapes, fruit setting rate is increased, and yield of the grapes is guaranteed; production is controlled after fruit bearing by setting the spica, the clusters are subjected to particle scattering, size of the spaca and flourishing growth of new shoots are strictly controlled, quality of the grapes is improved, and the sun rose grapes with good quality and steady production are obtained.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Corn fertilizer having pest resistance

InactiveCN108017440AGood nutrientsIncrease productionCalcareous fertilisersMagnesium fertilisersDiseaseCalcium bicarbonate

A corn fertilizer having pest resistance is composed of 40-45 parts of urea, 10-15 parts of potassium sulfate, 12-15 parts of calcium bicarbonate, 8-12 parts of biochar, 5-10 parts of boric acid, 2-5parts of sodium citrate, 2-8 parts of manganese sulfate, 10-20 parts of plant ash, 8-12 parts of magnesium sulfate, 3-5 parts of a sodium alginate solution, 0.5-0.8 part of a biological agent, 5-10 parts of traditional Chinese medicine extract product and 4-6 parts of a urease inhibitor. The corn fertilizer having pest resistance can provide good nutrition elements for corn, facilitates the prevention of root pests and root diseases of corn, does not cause soil hardening, and improves the soil quality; and the biochar is added into the fertilizer, so the traditional Chinese medicine extract can immersed in the pores of the biochar after undergoing ultrasonic treatment, thereby the fertilizer efficiency and the pest and disease resistance period can be prolonged, and the quality of the cornis improved. A preparation method of the fertilizer has the advantages of simplicity, easiness in implementation, and significant economic benefits. The fertilizer does not cause acid-base imbalanceafter being used; and the biological agent added to the feed increases beneficial bacteria in the soil and further increase the fertility of the soil.

Owner:龙里县康雅先蔬菜种植农场

Method for promoting cryptomere congealing of continuously casting molten steel

The invention relates to a method for accelerating the solidification of casting steel water, wherein it adds micro powder smaller than 20micrometer into steel water while the consumption is 0.05-5% of steel water, while said micro powder can be same material of steel water, or / and electrolyte iron powder. The corn shaper of said invention will not affect the components of steel water.

Owner:WUHAN IRON & STEEL ENG TECH GROUP

Lodging-resistant yield increasing wheat fertilizer

InactiveCN104418652AGood fertilizer effectStrong targetingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumEthephon

Owner:SHANDONG ENBAO BIOTECH

Spray type microbial fertilizer

InactiveCN103708919AIncrease profitEnhance photosynthetic intensityOrganic fertilisersAmmonium salt fertilisersPotassium carbonateBiology

The invention discloses a spray type microbial fertilizer. The spray type microbial fertilizer comprises boric acid, potassium carbonate, ammonium molybdate, citric acid, trace elements and a composite microbial inoculant. The spray type microbial fertilizer can substitute chemical fertilizers in the agricultural production, increases the foliar photosynthetic intensity of crops, increases the chlorophyll component, increases the stress resistance of the crops, inhibits the growth of harmful bacteria, and reduces diseases and pests.

Owner:TARIM UNIV

Compound fertilizer for corn planting and preparation method thereof

InactiveCN108911867AGood fertilizer effectStrong targetingBio-organic fraction processingExcrement fertilisersPhosphateLivestock

The invention discloses a compound fertilizer for corn planting, which consists of the following raw materials in parts by weight: 26-38 parts of plant ash, 51-69 parts of livestock and poultry excrement, 10-17 parts of Chinese herbal medicines, 3-7 parts of ground phosphate rock, 2-6 parts of bone powder, 6-12 parts of urea, 4-9 parts of potassium chloride, 2-5 parts of boric acid, 1-7 parts of amino acid, and 1-6 parts of calcium magnesium phosphate fertilizer. The prepared corn fertilizer has good fertilizer efficiency, strong pertinence, and fast nutrient absorption, and the utilization rate of the chemical fertilizer can be improved, the growth of a root system at a seedling stage is promoted, the viscosity of cell protoplasm can be improved, and the growth and development of crops are promoted. A variety of trace elements can not only promote the growth of seedlings, but also increase the number of grains in the later stage, so as to improve yield and quality. A fertilizer preparation method of the invention is simple and feasible, and the economic benefit is remarkable. With the fertilizer, soil acidity and alkalinity does not be disturbed, soil fertility can be further increased, and economic benefits are created for farmers.

Owner:无为县松林生态养殖有限公司

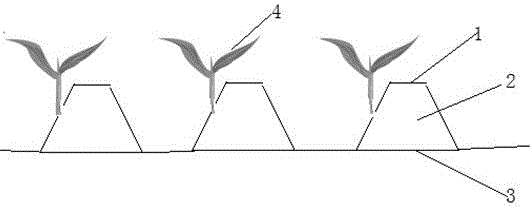

Method for improving corn output through condensed planting

InactiveCN106508185AImprove pollination rateIncrease productionPlant cultivationCultivating equipmentsSurface moistureSludge

The invention relates to a method for improving corn output through condensed planting, and belongs to the technical field of agriculture. The method is implemented through steps of firstly, immersing corn seeds in hexamine solution, and dropwise adding phytic acid during the immersing process; after dropwise adding, stirring evenly and immersing for 8-10 hours; draining and drying to remove surface moisture; preparing the dried seeds to be rice paste; and then blending seeds in acid-sludge powder of table vinegar and obtaining the pre-treated corn seeds for future use; deeply loosening soil and then ridging, wherein the ridge direction is 25 degrees on the magnetic south by west, and the ridge is in the shape of trapezoid; then monoseeding at one side of the trapezoid ridge; after seedling, performing the regular farm field management. Through changing the ridge in due south and north directions to an oblique ridge, the ridge is fully ventilated and light-transmitted to reach the best illumination; meanwhile, the method improves the corn fertilization rate, increases the seed number of insemination and development, reduces the empty seed; meanwhile, the cluster is fast in development speed, output is high and quality is good.

Owner:ANHUI TIANFENG LIVESTOCK BREEDING TECH

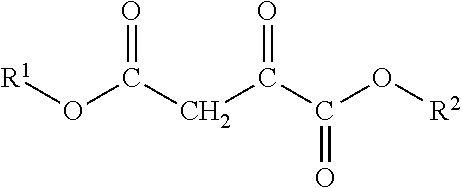

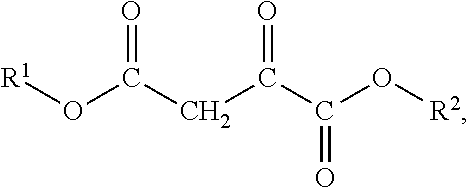

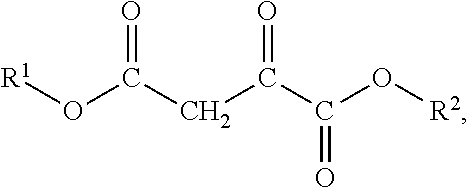

Composition for regulating plant growth, method for treating plants therewith, and active ingredient thereof

InactiveUS20190119193A1Improve germination rateImprove scalabilityBiocidePlant growth regulatorsAcetic acidGrowth plant

A composition for regulating plant growth, the active ingredient of which is an ester of oxaloacetic acid or a salt thereof, or derivatives thereof, wherein the ester of oxaloacetic acid has the formula set forth below, where R1 and R2 are independently selected from a series of C1-C18 alkyl groups, and wherein the content of the active ingredient corresponds to a concentration of from 10−11 M to 10−3 M. The active ingredients and compositions for regulating plant growth allow for treating plants in order to stimulate the growth thereof and achieve such advantages as increased yields, improved plant quality, improved nutrient absorption and enhanced stress resistance, while allowing such advantages to be achieved using a relatively small amount of an active ingredient(s) which is / are biodegradable and environmentally friendly.

Owner:STARIKOV IVAN ALEKSANDROVICH

Plant growth regulator for reducing high-temperature damage to paddy, use method and application thereof

InactiveCN106889080AThe effect of preventing heat damageIncrease photosynthetic rateBiocidePlant growth regulatorsGrowth plantCell division

The invention discloses a plant growth regulator for reducing high-temperature damage to paddy, a use method and application thereof. The regulator comprises cytokinin and auxin at weight ratio of (0.1-1.2) to (0.15-0.6); the regulator also can include cytokinin at a certain ratio; in a use process, an aqueous solution is adopted by the plant growth regulator, wherein the cytokinin is 30mg / L-100mg / L, the auxin is 10mg / L-50mg / L and acetylcysteine is 50mg / L-150mg / L; the fertilizer is applied to the leaves in the meiophase stage of paddy pollen mother cells and the dosage is 40-60 liters / mu; the plant growth regulator can be used for relieving the high-temperature damage to paddy, can guarantee high and stable yield of the paddy, is suitable for paddy area over the middle and lower reaches of the Yangtze river and is especially suitable for application in high-temperature area in florescence stage.

Owner:新昌县拜特夫农业科技有限公司

Total-nutrient yield increasing corn fertilizer with high efficiency

InactiveCN104418654AGood fertilizer effectStrong targetingAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassium hydroxideNutrient absorption

The invention discloses a total-nutrient yield increasing corn fertilizer with high efficiency. The fertilizer is characterized by comprising the following components in parts by weight: 35-40 parts of urea, 10-20 parts of humic acid, 5-10 parts of itaconic acid, 10-20 parts of ammonium dihydrogen phosphate, 5-10 parts of potassium hydroxide, 10-20 parts of boric acid, 3-5 parts of zinc sulfate, 3-5 parts of sodium alginate solution and 3-5 parts of EDTA (ethylene diamine tetraacetic acid). With relatively comprehensive nutrient elements and active organic matters, the prepared fertilizer has good efficiency and strong pertinence and is quick in nutrient absorption, so that the utilization rate of the chemical fertilizer can be increased. Not only can seedling growth be promoted but also the grain number at the later stage can be increased by adopting various trace elements, so that the yield is increased and the quality is improved. A preparation method of the fertilizer is simple and practicable and has obvious economic benefits.

Owner:SHANDONG ENBAO BIOTECH

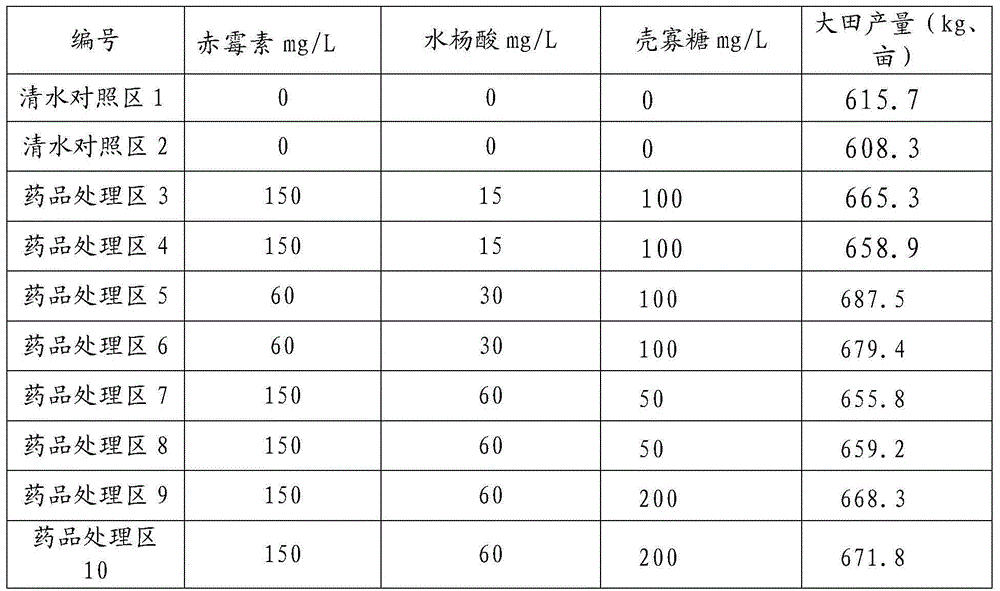

A plant growth conditioner for reducing rice high temperature damage, its use method and application

ActiveCN104054706BThe effect of preventing heat damageIncrease photosynthetic rateBiocidePlant growth regulatorsGrowth plantTemperature conditioning

The invention discloses a plant growth conditioner for reducing damage caused by high temperature to rice, and a using method and application of the plant growth conditioner. The conditioner comprises gibberellin and salicylic acid, wherein the weight ratio of gibberellin to salicylic acid is (0.5-1.5):(0.15-0.6). The conditioner can also comprise chitosan oligosaccharide according to a certain ratio. When the conditioner is used, an aqueous solution form is adopted, wherein an aqueous solution is prepared from 50 to 150mg / L of gibberellin, 15 to 60mg / L of salicylic acid and 50 to 200mg / L of chitosan oligosaccharide, and is applied to leaves in a spraying way during the meiosis stage of pollen mother cells of rice, and 30 to 45 liters of aqueous solution is applied to each acre. The plant growth conditioner can be applied to reduce the damage caused by high temperature to rice, and is suitable for popularization and application in a rice culturing region on the middle and lower reaches of Changjiang River, particularly in a region at which the temperature in a flowering period is always high, and high and stable yield of rice is ensured.

Owner:CHINA NAT RICE RES INST

Quartz crucible use process for meeting pulling of multiple single crystals

InactiveCN110592663AAccelerate the crystallization rateReduce corrosionPolycrystalline material growthBy pulling from meltQuartz crucibleCorrosion

The invention provides a quartz crucible use process for meeting pulling of multiple single crystals. In a section refeeding process of pulling of single crystals, a certain amount of aluminum hydroxide is added; and in addition, along with increase of the number of pulled single crystals, the aluminum hydroxide is replenished to replenish dropped crystal evolution layers, and a quartz crucible istransformed into a stable alpha-cristobalite structure. The process has the beneficial effects that due to addition of the aluminum hydroxide, transformation of the quartz crucible to the stable alpha-cristobalite structure is accelerated, the dropped crystal evolution layers can be replenished, corrosion of a silicon solution to the quartz crucible can be reduced, the service life of the quartzcrucible can be prolonged, and cost reduction and effect improvement can be achieved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Solder wire with rear earth reinforced bead weld flux core

InactiveCN110814573AHigh hardnessImprove wear performanceWelding/cutting media/materialsSoldering mediaMetallurgyFerrosilicon

The invention belongs to the technical field of bead weld materials and specially relates to a solder wire with a rear earth reinforced bead weld flux core. According to the solder wire with the rearearth reinforced bead weld flux core, the flux core is prepared from the following chemical components including, by weight, 0.2-0.6% of carbon, 0.4-0.8% of ferroboron, 1-1.5% of ferrochrome, 1-3% offerro-molybdenum, 0.2-1.0% of sodium fluoride, 0.2-1.5% of potassium titanate, 0.2-0.8% of yttrium-base heavy rare earth ferrosilicon, 0.8-1.8% of ferromanganese and the balance Fe. The solder wire has good abrasion resistance and red hardness and is capable of preventing stripping of bead weld layers.

Owner:湖北秦鸿新材料有限公司

Ecological and organic corn fertilizer and preparation method thereof

InactiveCN108546202AHigh yieldAbsorption rate reduction effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSulfateDissolving pulp

The invention discloses an ecological and organic corn fertilizer and a preparation method thereof, belonging to the technical field of fertilizers. The ecological and organic corn fertilizer containsurea, ammonium dihydrogen phosphate, potassium sulfate, zinc sulfate, vinegar residue, polylysine sodium, ferrous sulfate and dissolved pulp. The ecological and organic corn fertilizer is prepared through stirring, mixing and pulping. By utilizing polylysine sodium, ferrous sulfate and dissolved pulp for reinforcement, the yield of corns is increased, and the heavy metal absorptivity resistance of the corns is improved.

Owner:长沙浩然医疗科技有限公司

Soil-improving organic compound fertilizer for corn

InactiveCN106927975APromote growthImprove protectionCalcareous fertilisersAnimal corpse fertilisersManganesePhosphoric acid

The invention discloses a soil-improving organic compound fertilizer for corn. The soil-improving organic compound fertilizer for corn is prepared from the following raw materials in parts by weight: 2-8 parts of attapulgite powder, 1-4 parts of coal gangue, 1-4 parts of brown coal powder, 20-30 parts of a medical stone compound, 2-4 parts of borax, 1-3 parts of gypsum powder, 1.5-2.5 parts of diaminoferric xanthohumate, 0.8-1.6 parts of fulvic manganese, 30-50 parts of flue ash potash, 20-30 parts of potassium monohydrate, 50-70 parts of ammonium nitrate, 8-18 parts of radish leaves, 10-20 parts of shell powder, 6-12 parts of activated carbon, 4-8 parts of microcrystalline cellulose, 8-16 parts of turfy soil and 5-8 parts of citric acid residue. The soil-improving organic compound fertilizer for corn is rich in nutrition, is capable of increasing the use ratio of chemical fertilizer, is beneficial to the growth of root system in seedling stage, has excellent heat resistance and water retaining capacity, is capable of increasing the yield, improving the quality and increasing the nutrition content, has an excellent protection function for soil and is capable of repairing soil and promoting the soil fertility.

Owner:蚌埠市兵凤赟种植农民专业合作社

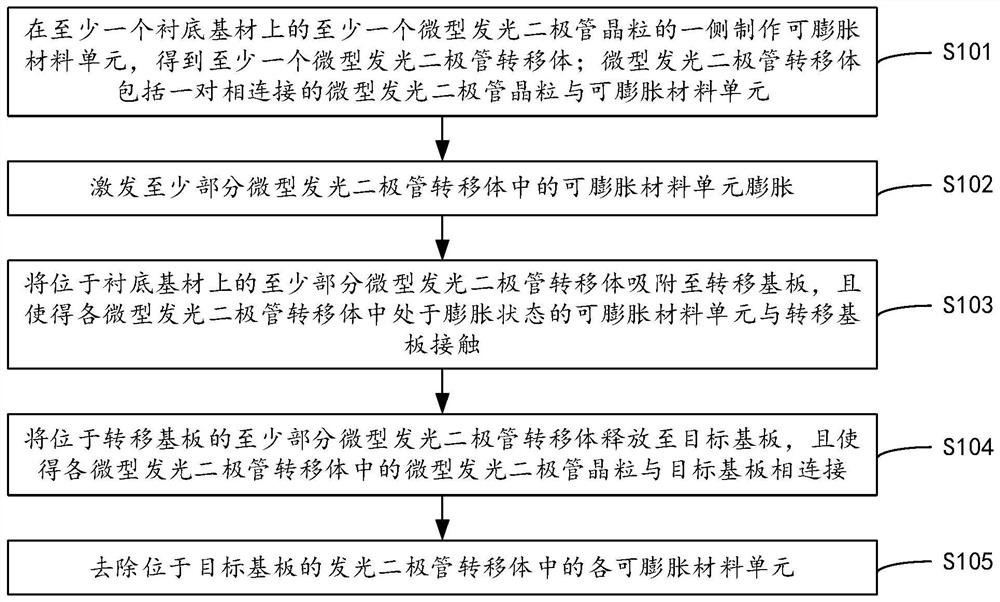

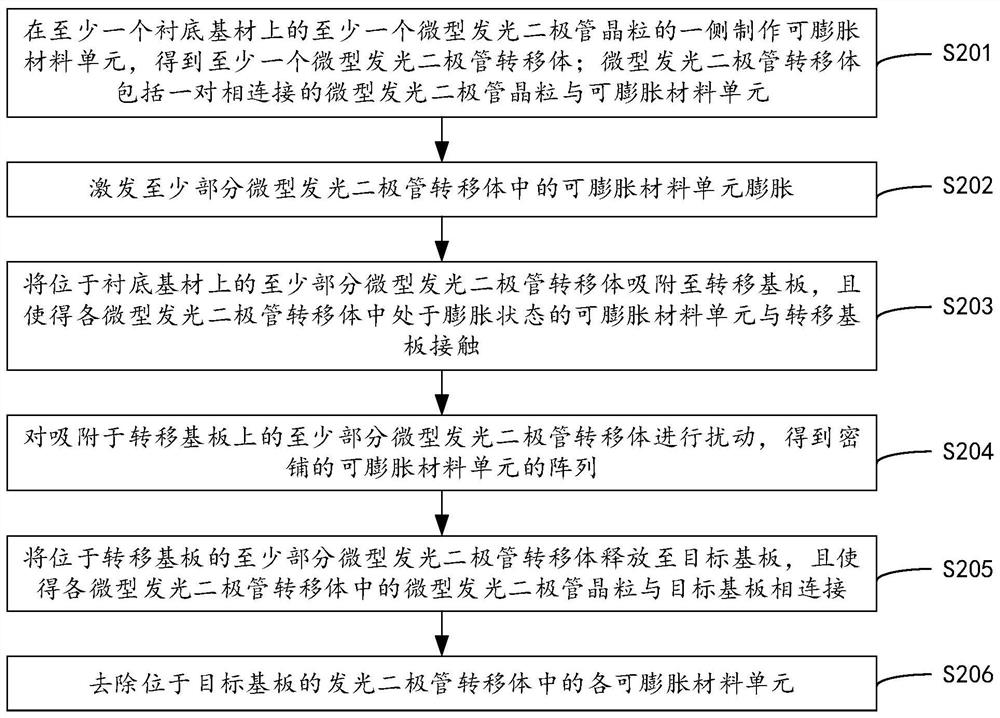

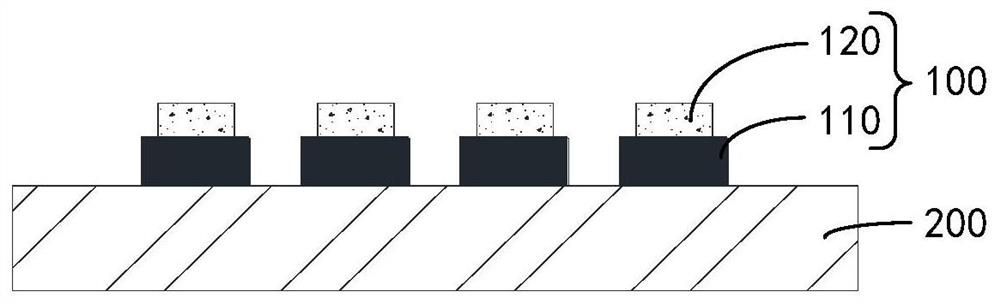

Transfer method and transfer device for micro light-emitting diode

ActiveCN112582308AIncrease the number of grainsIncrease spacingSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsEngineering

The embodiment of the invention provides a transfer method and a transfer device of a micro light emitting diode. The transfer method comprises the following steps of manufacturing an expandable material unit at one side of at least one micro light-emitting diode grain on at least one substrate base material to obtain at least one micro light-emitting diode transfer body; exciting the expandable material unit in at least part of the micro light-emitting diode transfer body to expand; adsorbing at least part of the micro light-emitting diode transfer body on the substrate base material to a transfer substrate; releasing at least part of the micro light-emitting diode transfer bodies located on the transfer substrate to a target substrate; and removing each expandable material unit in the light emitting diode transfer body of the target substrate. According to the embodiment of the invention, the spacing of the micro light-emitting diode grains in the transfer process is adjustable, so that the preparation efficiency of the micro light-emitting diode can be improved, and the preparation period is shortened.

Owner:FUZHOU BOE OPTOELECTRONICS TECH CO LTD +1

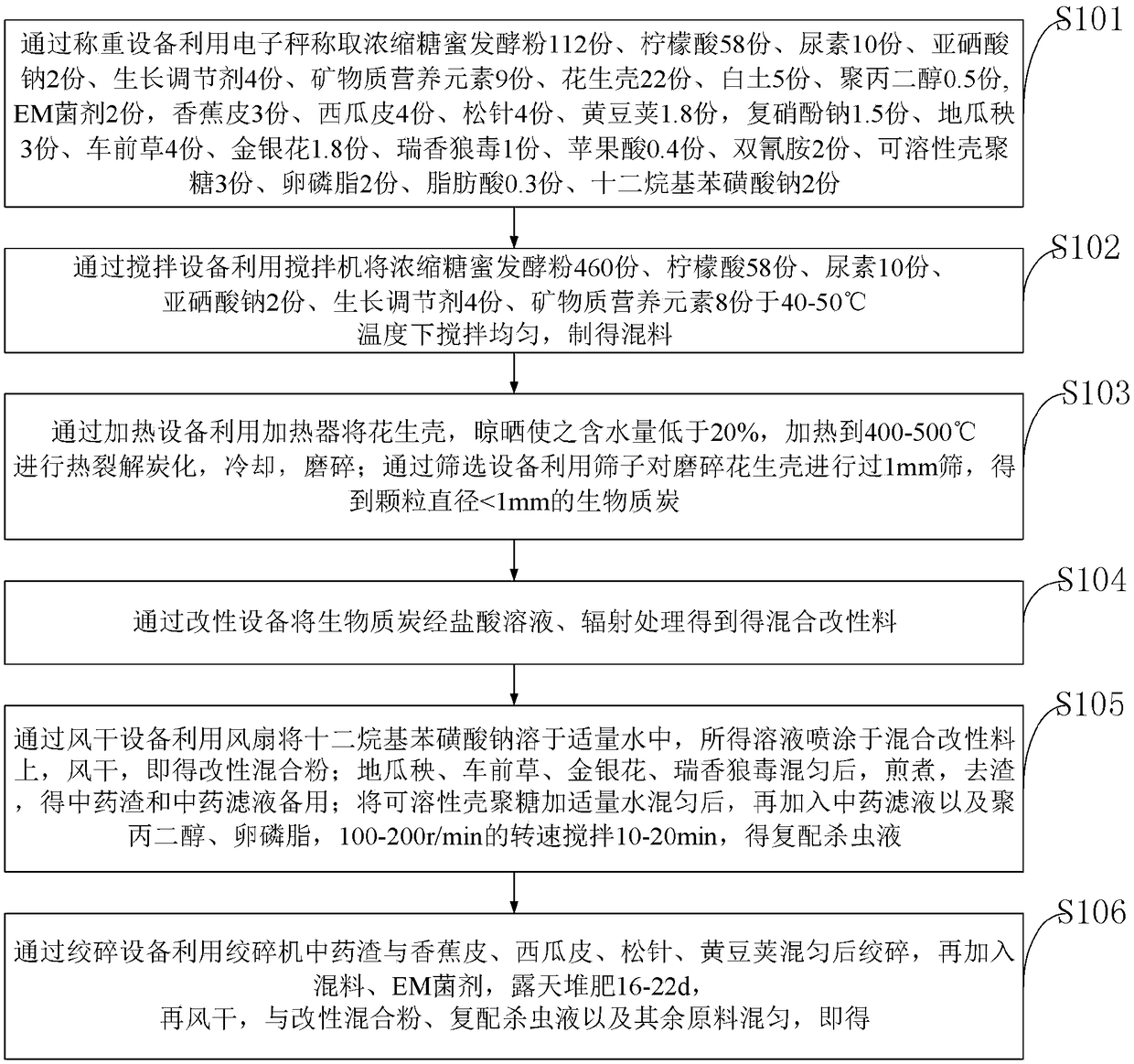

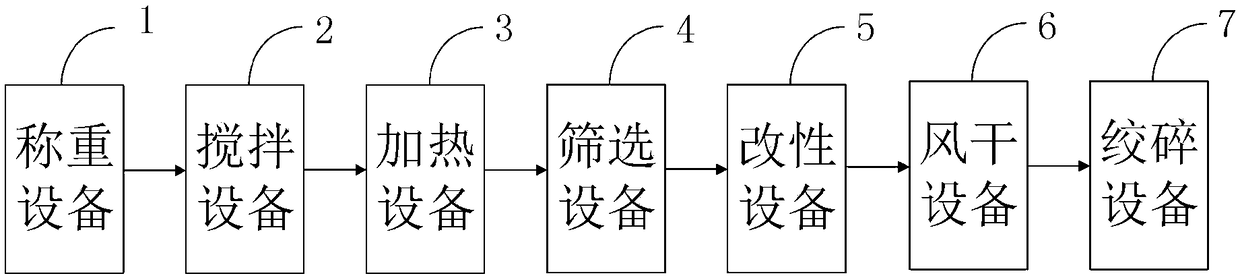

Novel selenium-rich peanut fertilizer additive and preparation method thereof

InactiveCN109384589AReduce transpiration rateGood fertilizer effectBio-organic fraction processingBioloigcal waste fertilisersNutrient absorptionChemistry

The invention belongs to the technical field of preparation of fertilizers, and discloses a novel selenium-rich peanut fertilizer additive and a preparation method thereof. The preparation method comprises the following steps: weighing components of the novel selenium-rich peanut fertilizer additive with an electronic scale; evenly stirring through a stirrer to obtain a mixture; implementing thermal cracking and carbonizing with a heater, cooling, and grinding; sieving grinded peanut shells with a sieve to obtain biomass charcoal; treating the biomass charcoal through a hydrochloric acid solution and irradiation to obtain a mixed modified material; mixing to obtain a compound insecticide solution; and evenly mixing the mixture with the mixed modified powder, the compound insecticide solution and the other raw materials. A fertilizer provided by the invention is good in fertilizer efficiency and is strongly targeted, nutrients are rapidly absorbed, the defect of insufficient nutrient absorption of a root part is overcome, the fertilizing method is simple and feasible, the economic benefits are remarkable; sodium selenite instead of sodium selenate is applied in the selenium-rich fertilizer, so that a health threat of the fertilizer to a producer and a consumer is avoided.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

ZnO modified SnO2-based perovskite solar cell and preparation method thereof

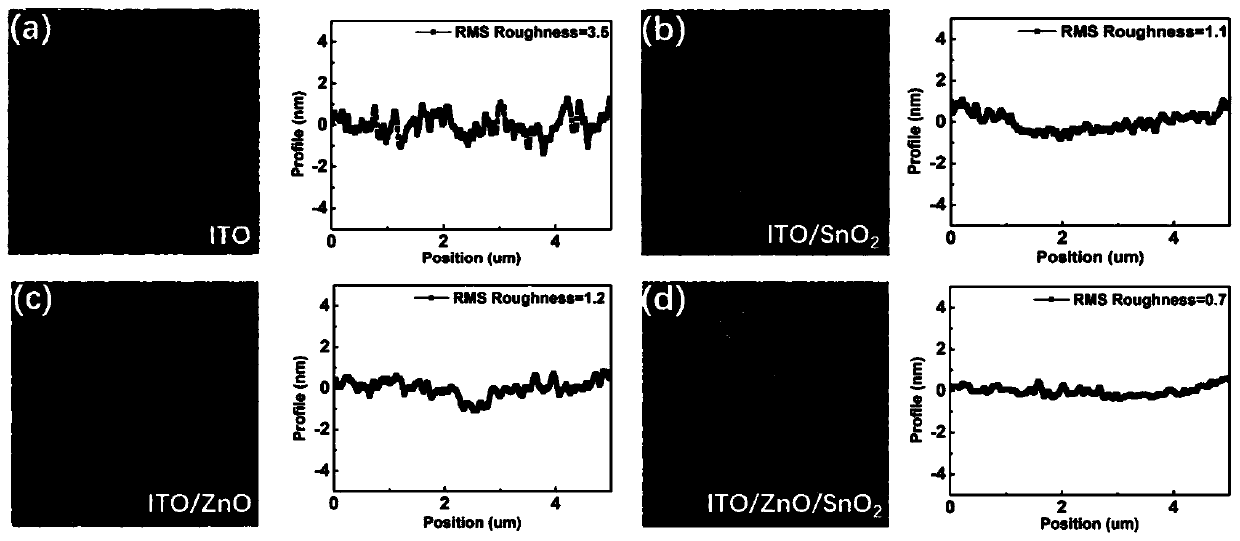

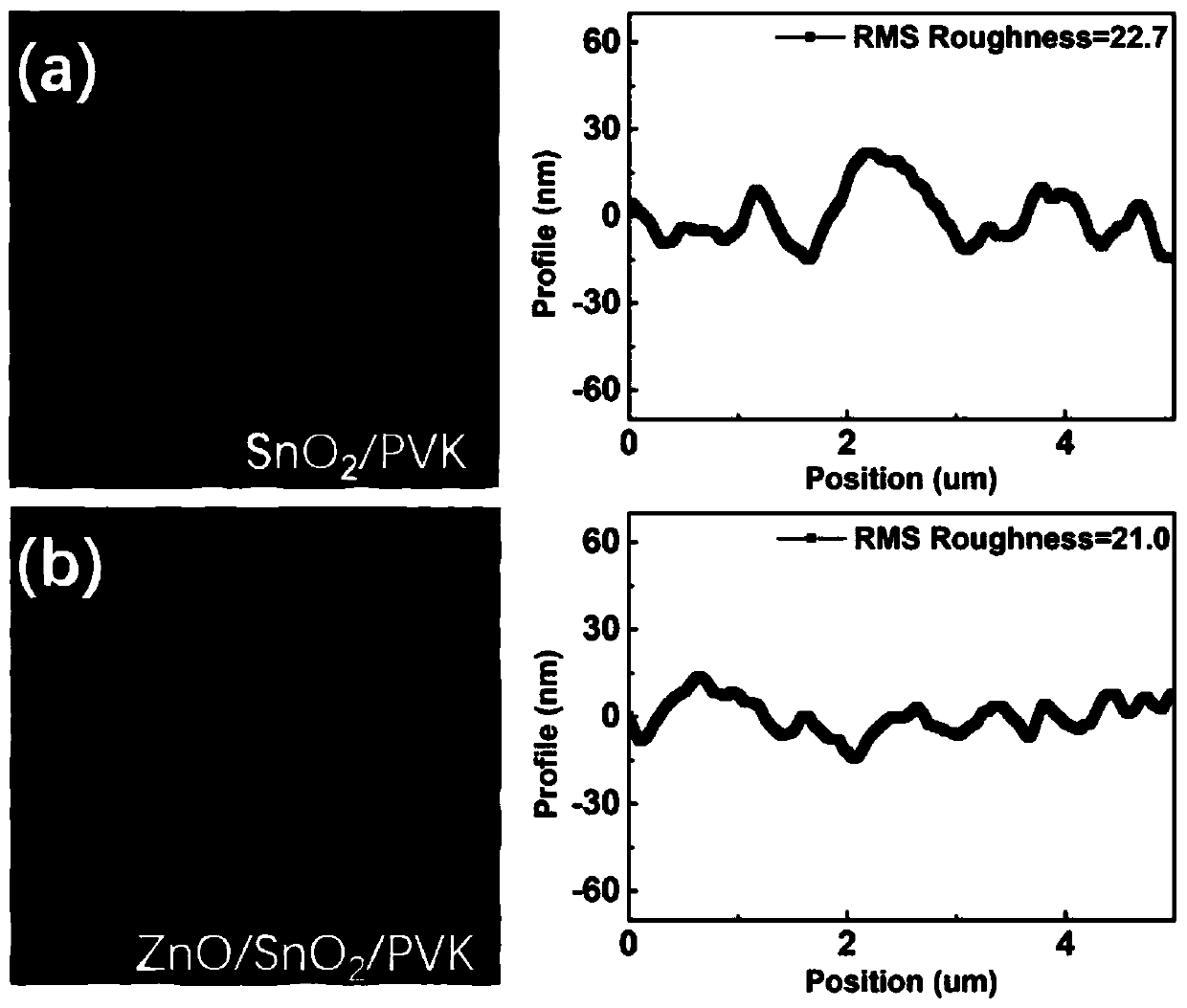

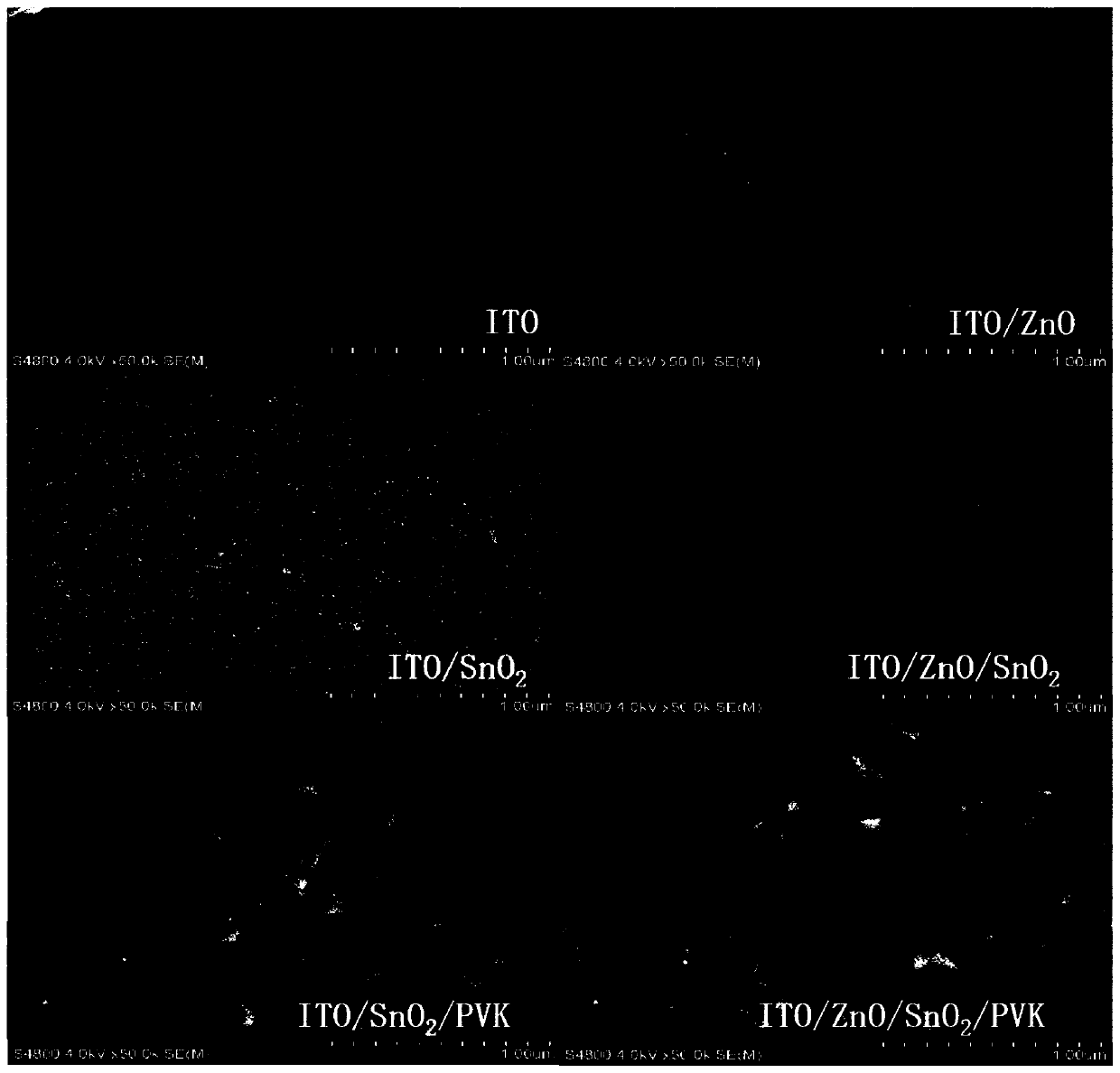

ActiveCN110311041AInhibition of protonation reactionsReduce roughnessMaterial nanotechnologySolid-state devicesPerovskite solar cellCompetitive growth

The invention discloses a ZnO modified SnO2-based perovskite solar cell and a preparation method thereof. The solar cell includes a conductive glass layer, a ZnO modification layer, a SnO2 electron transport layer, a perovskite layer, a hole transport layer and a metal electrode layer which are sequentially layered, wherein the ZnO modification layer does not directly modify contact surfaces of the SnO2 electron transport layer and the perovskite layer, but is reversely disposed on a side of the SnO2 electron transport layer away from the perovskite layer, so a surface of the SnO2 electron transport layer close to the perovskite layer is modified, and roughness of the SnO2 electron transport layer is reduced. The solar cell is advantaged in that roughness reduction of the SnO2 electron transport layer further increases the number of crystal grains of the perovskite, competitive growth among the grains reduces roughness of the perovskite layer, moreover, the ZnO modification layer can directly improve interface contact between the SnO2 electron transport layer and the conductive glass layer.

Owner:COLLEGE OF SCI & TECH NINGBO UNIV

Peanut underground fertilizer with effect of increasing yield at early stage

The invention discloses a peanut underground fertilizer with an effect of increasing yield at an early stage. The fertilizer is characterized by comprising the following components in parts by weight: 10-20 parts of corn straw powder, 15-25 parts of nitrogen, phosphorus and potassium compound fertilizer, 6-8 parts of humic acid, 8-10 parts of itaconic acid, 1.5-2.5 parts of trace elements, 0.2-0.5 part of growth regulator and 40-60 parts of water. The chemical fertilizer utilization rate and the grain number at the later stage can be increased by adopting the prepared fertilizer, so that the yield is increased and the quality is improved. The fertilizer has good efficiency and strong pertinence, is quick in nutrient absorption and makes up for the deficiency of roots in nutrient absorption. A fertilizer application method is simple and practicable and has obvious economic benefits.

Owner:SHANDONG ENBAO BIOTECH

A kind of mg-zn-gd quasicrystal-reinforced az91 magnesium alloy and its preparation method

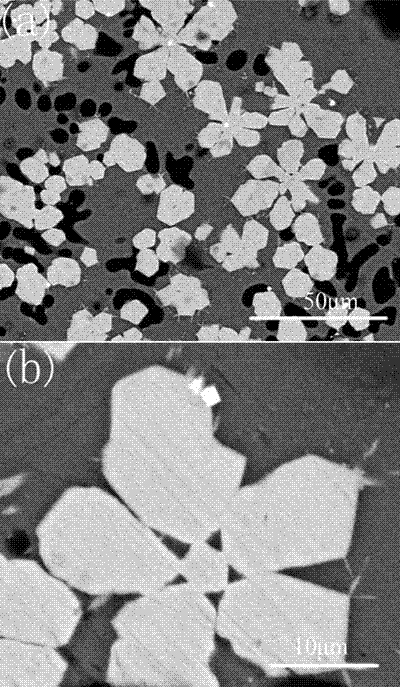

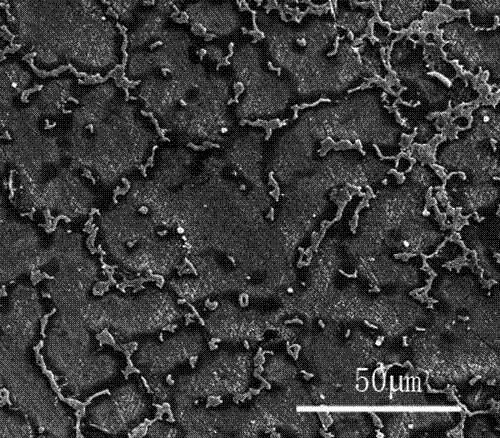

ActiveCN105331866BImprove mechanical propertiesAccelerated corrosionQuasicrystalUltimate tensile strength

The invention relates to Mg-Zn-Gd quasi-crystal strengthened AZ91 magnesium alloy. The Mg-Zn-Gd quasi-crystal strengthened AZ91 magnesium alloy is characterized by comprising, by mass, 8.18-8.82% of Al, 1.90-5.16% of Zn, 0.29-1.36% of Gd and the balance Mg. The Mg-Zn-Gd quasi-crystal alloy clear in tissue and even in component is obtained; quasi-crystal intermediate alloy is added to traditional AZ91 alloy; the AZ91 alloy and the quasi-crystal intermediate alloy with the mass percent of 2%-10% are smelted at the same time through reasonable technology means; and then the Mg-Zn-Gd quasi-crystal strengthened AZ91 magnesium alloy is obtained. The specific strength and the specific rigidity of the magnesium alloy are ensured, meanwhile, strength, plasticity and corrosion resistance of the alloy are remarkably improved, and good comprehensive performance is obtained. The AZ91 alloy prepared through the method can be more widely applied to the fields of rail transit, automobiles, electronics, communication and the like.

Owner:UNIV OF JINAN

Method for producing tungsten bar serving as halogen tungsten lamp tungsten filament

The invention provides a method for producing a tungsten bar serving as a halogen tungsten lamp tungsten filament, comprising the following steps of: material selecting, pre-reducing, high potassium doping, reducing, acid rinsing, powder preparing, cold static pressure shaping, high temperature sintering and the like. Compared with the conventional technology, the method is characterized in that two crystal ammonium paratungstates are utilized to prepared raw materials, high potassium doping is adopted, preparation of middle granule tungsten powder is added, a powder distribution scheme is optimized by the middle granule tungsten and a unique incipient fusion high temperature sintering process is utilized. In the method, the granularity distribution of the tungsten powder avoids the peak or double peak phenomenon and has good normal distribution, after being sintered at high temperature, the cross section crystal of the tungsten bar is thin and uniform; the tungsten bar is pressed by a powder mixing scheme; according to a forming mechanism of potassium foams, the number of tungsten bar cross section crystal grains is increased; and the partial growth of the crystal grains is avoided so that the potassium foam is small in aperture, large in density, multiple in crystal boundary, long in line and uniform in distribution.

Owner:GANZHOU HONGFEI TUNGSTEN & MOLYBDENUM MATERIALS

Method for promoting fine crystal solidification of continuously casting molten steel

ActiveCN100591439CFinal Chemical Composition ImpactLow content of impurity elementsIron powderMolten steel

Owner:WUHAN IRON & STEEL ENG TECH GROUP

Amino acid liquid fertilizer and application thereof in corn planting

ActiveCN108610097APhenotype improvementImprove planting effectFertilising methodsCereal cultivationGrain weightArginine

The invention relates to an amino acid liquid fertilizer and application thereof in corn planting, and particularly provides an amino acid liquid fertilizer. The amino acid liquid fertilizer comprisesamino acid and the balance of water, and the amino acid is arginine or glutamine. The invention further provides a corn planting method. The method comprises the steps of spraying the amino acid liquid fertilizer for corns. The invention further provides application of the amino acid which is the arginine or the glutamine in the improvement of a corn filling effect. The amino acid liquid fertilizer is simple in formula, convenient to use and remarkable in fertilizer efficiency, is used for corn planting, and can comprehensively improve the corn filling effect, particularly, corncob phenotypesare improved remarkably (including improvement of grain plumpness, increasing of lengths of spike-stalks, increasing of the number of grains and relieving of bare tips), and thousand seed weight, kernels per spike, grain weight per spike, grain type carotene concentration and the like are improved.

Owner:CHINA AGRI UNIV

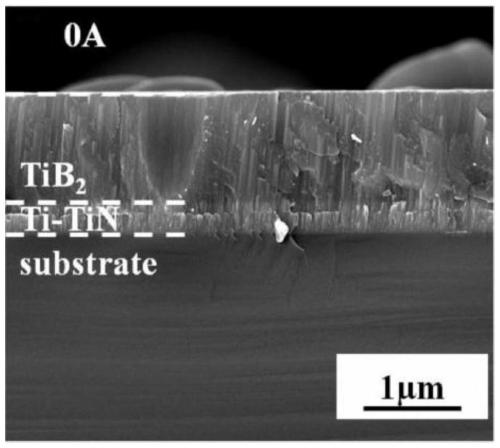

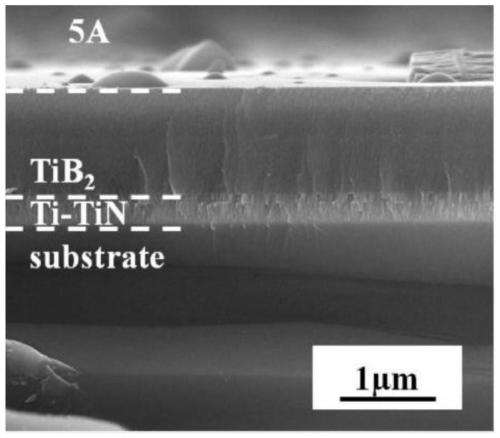

Compact titanium diboride coating, preparation method of compact titanium diboride coating and application of compact titanium diboride coating

ActiveCN110484881ACompact structureImprove surface qualityVacuum evaporation coatingSputtering coatingHardnessWear resistance

The invention belongs to the technical field of surface protection, and discloses a compact titanium diboride coating, a preparation method of the compact titanium diboride coating and application ofthe compact titanium diboride coating. The titanium diboride coating sequentially comprises a Ti transition layer, a Tin overplating layer and a TiB2 layer, wherein titanium diboride existing in the TiB2 layer is in the form of (001) preferentially oriented nano-isometric crystal; the grain diameter of the isometric crystal is 2-5 nm; the titanium diboride coating is prepared by taking a TiB2 target as a raw material and adopting a magnetron sputtering composite ion beam etching method by a coating mechanism; and the coating machine comprises a vacuum chamber, a magnetron sputtering source, anion source and workpiece supports capable of rotating at the same time. The TiB2 coating has excellent toughness and compact structure; and the compact titanium diboride coating and the preparation method have the advantages of being simple in process, high in film forming quality, stable in performance, extremely high in hardness and excellent in friction wear resistance, and widely applicable to protecting the surfaces of products such as machinery and molds.

Owner:GUANGDONG UNIV OF TECH

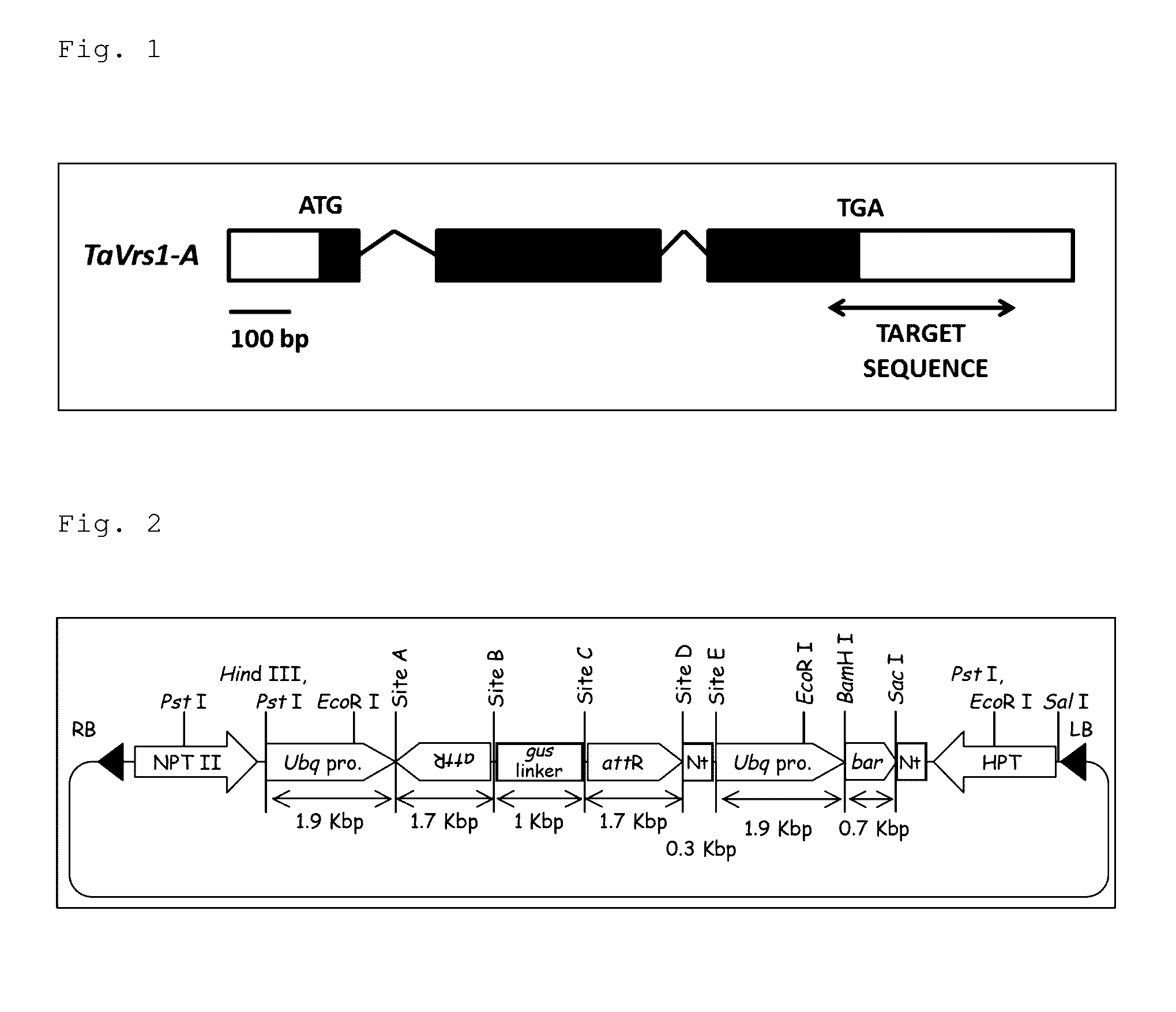

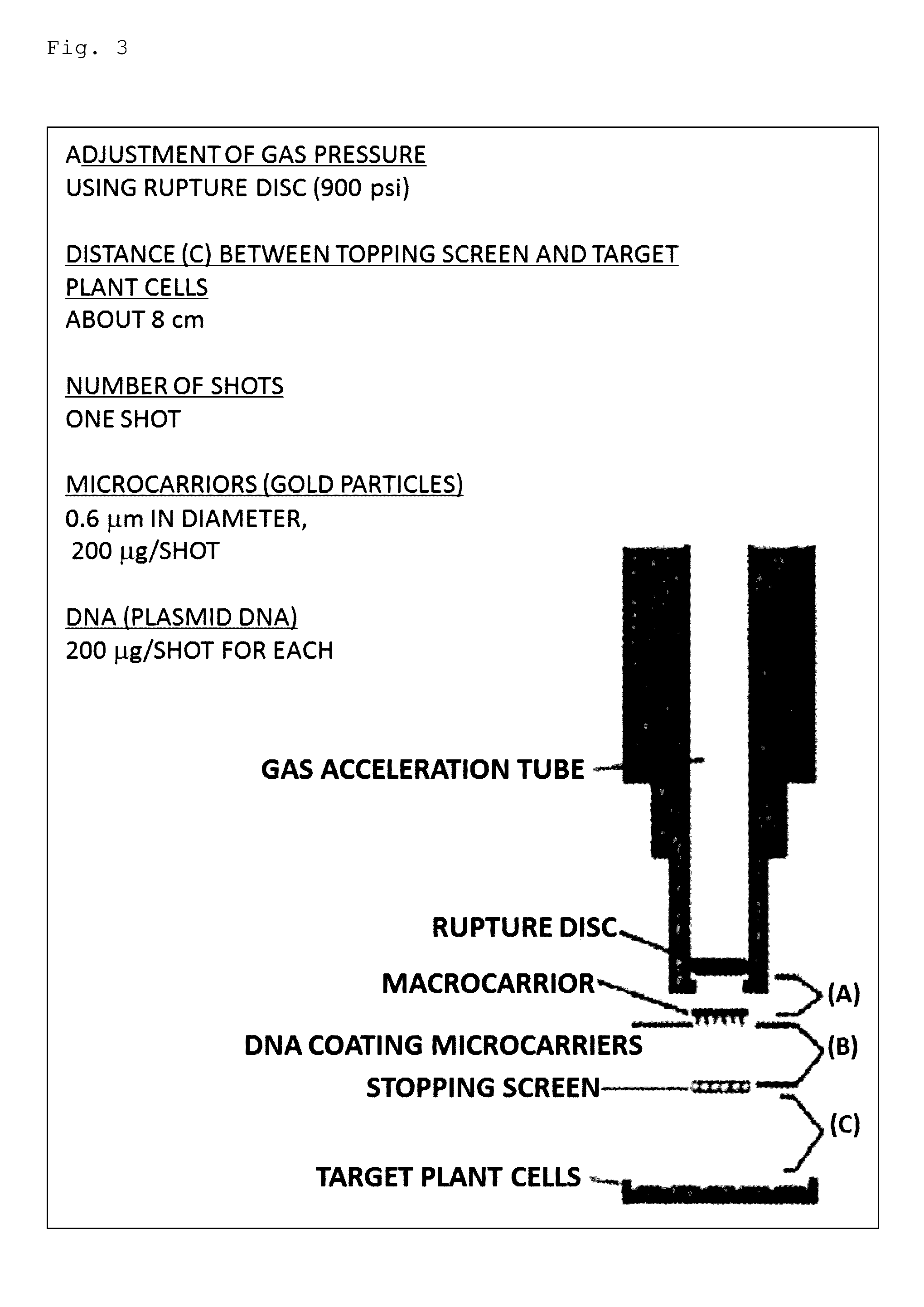

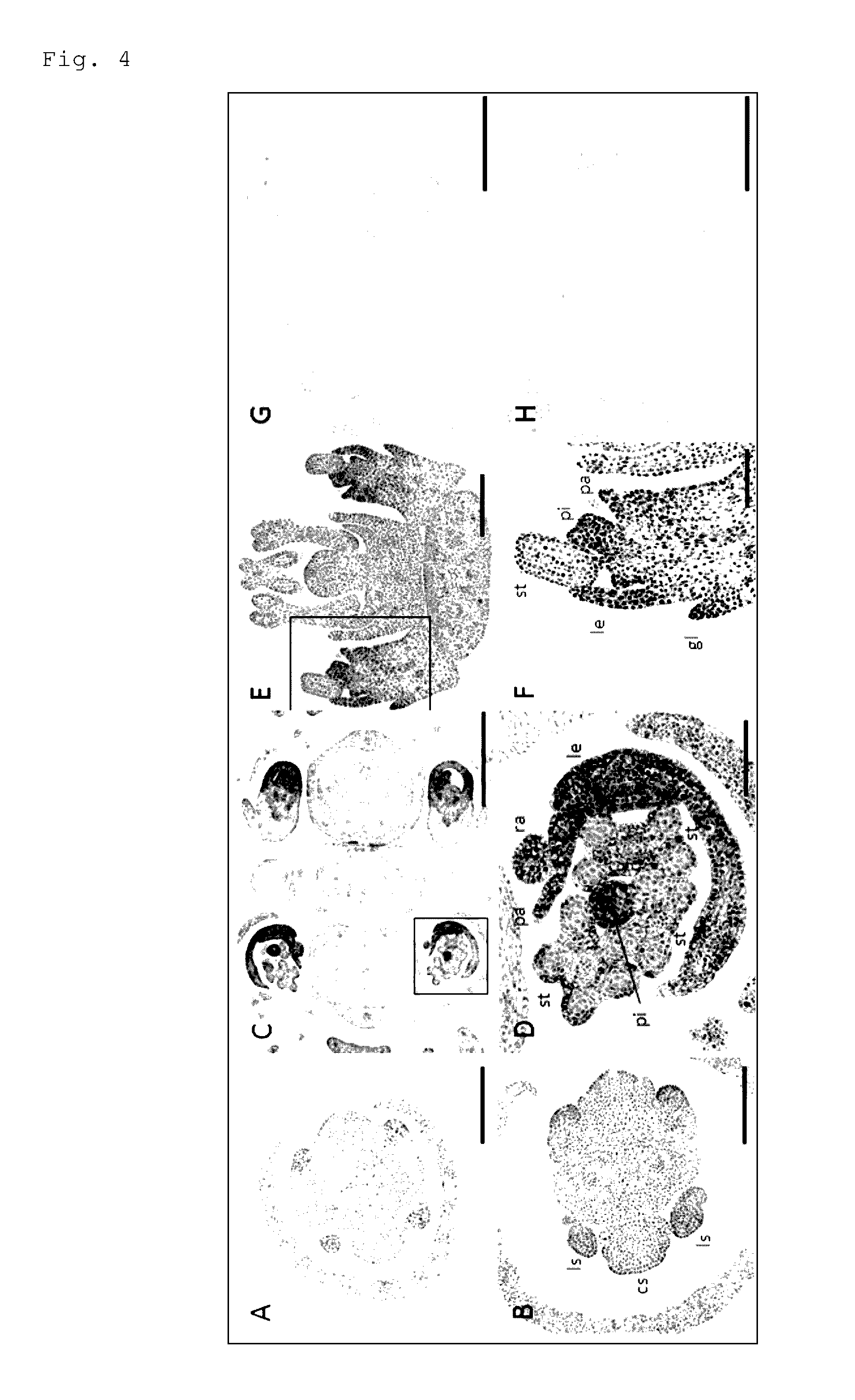

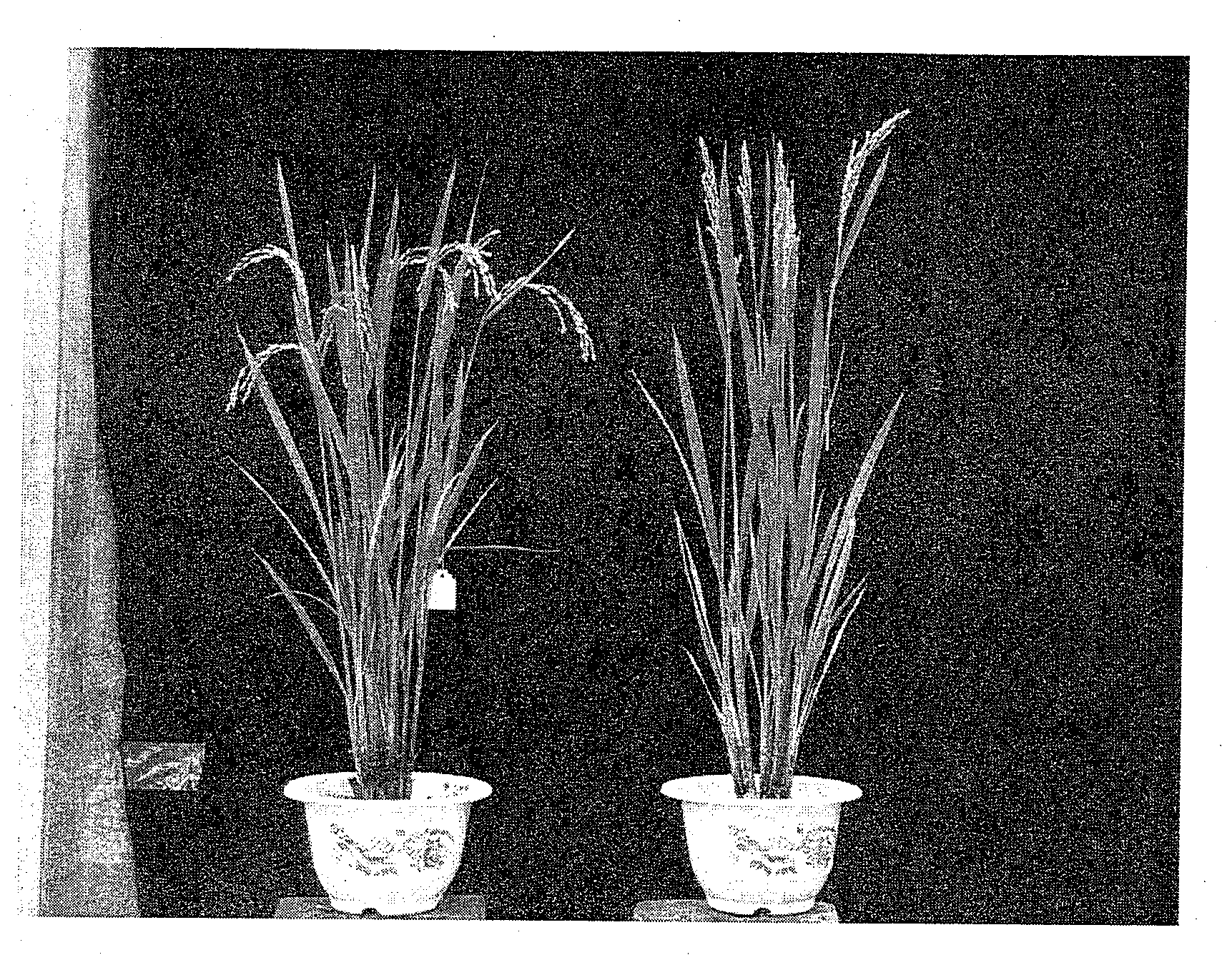

Wheat with increased number of grains and method for producing the same, and agent for increasing the number of wheat grains

InactiveUS20160281103A1Increase the number ofIncrease the number of grainsClimate change adaptationVector-based foreign material introductionBiotechnologyTriticeae

The Vrs1 gene was found to be highly expressed in the pistils of sterile lateral spikelets of two-row barley, showing that the VRS1 protein suppresses the fertility of florets in lateral spikelets. In addition, it was also found that the introduction of siRNA specific to the Vrs1 gene into two-row barley successfully restored the fertility of lateral spikelets and thus can increase the number of grains. The vrs1 gene derived from wheat was isolated for the first time, and the expression site of the gene was found to be specific to upper florets to be sterile in spikelets. Furthermore, it was confirmed that the introduction of siRNA specific to the wheat Vrs1 gene into wheat successfully increased the number of florets and the number of grains per spikelet, enabling provision of a method and an agent for increasing the number of grains per spikelet of wheat.

Owner:NAT INST OF AGROBIOLOGICAL SCI

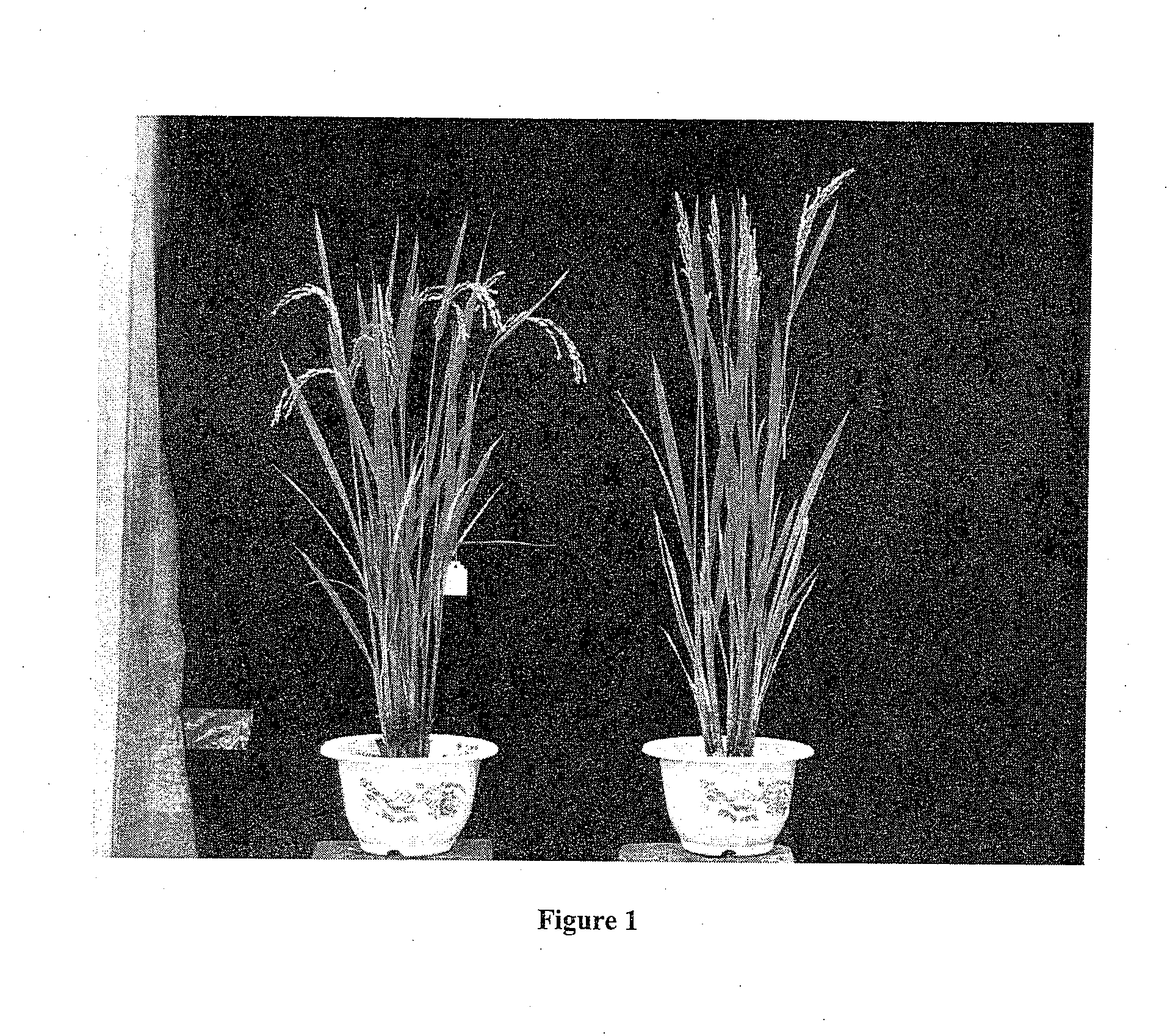

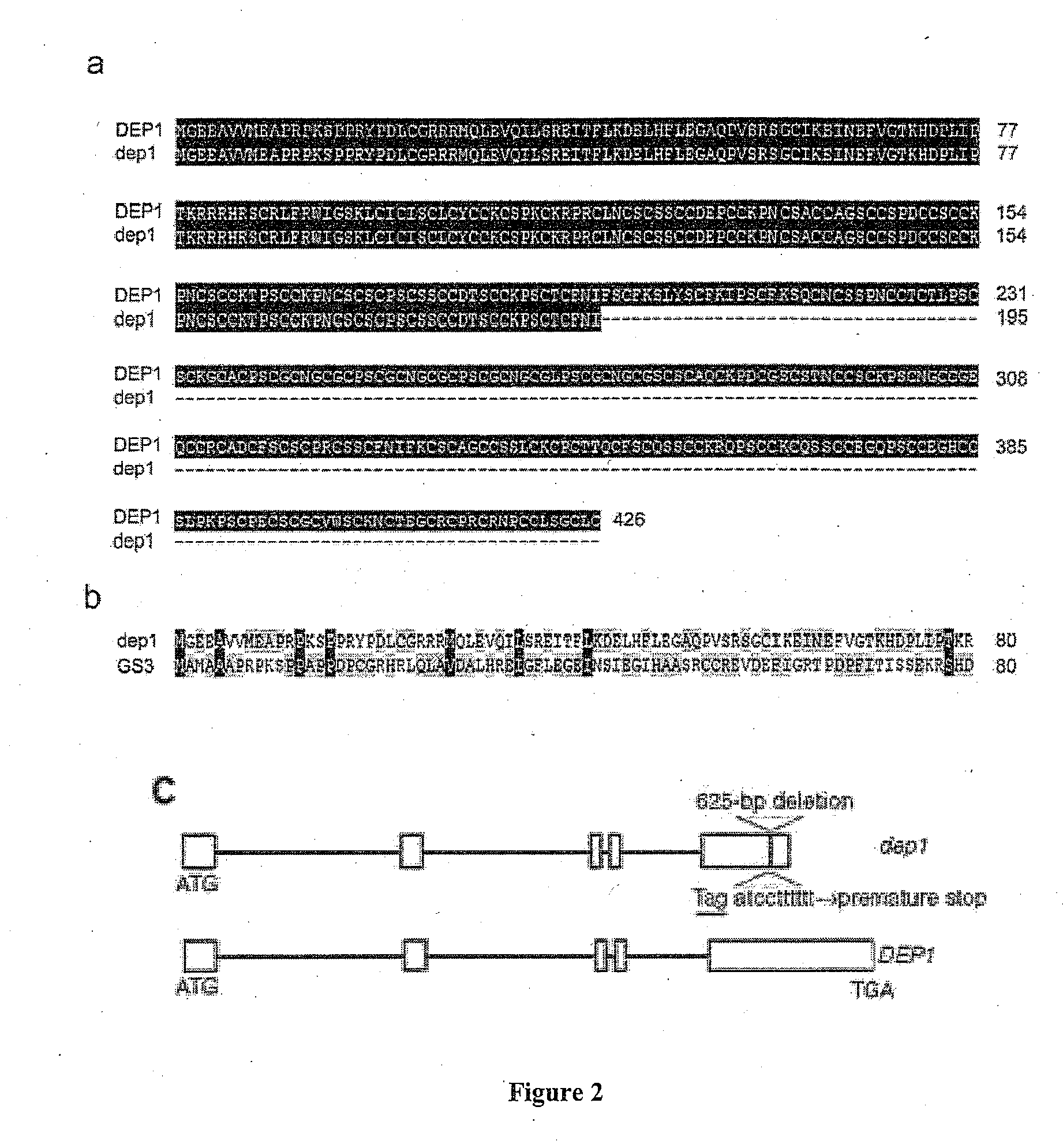

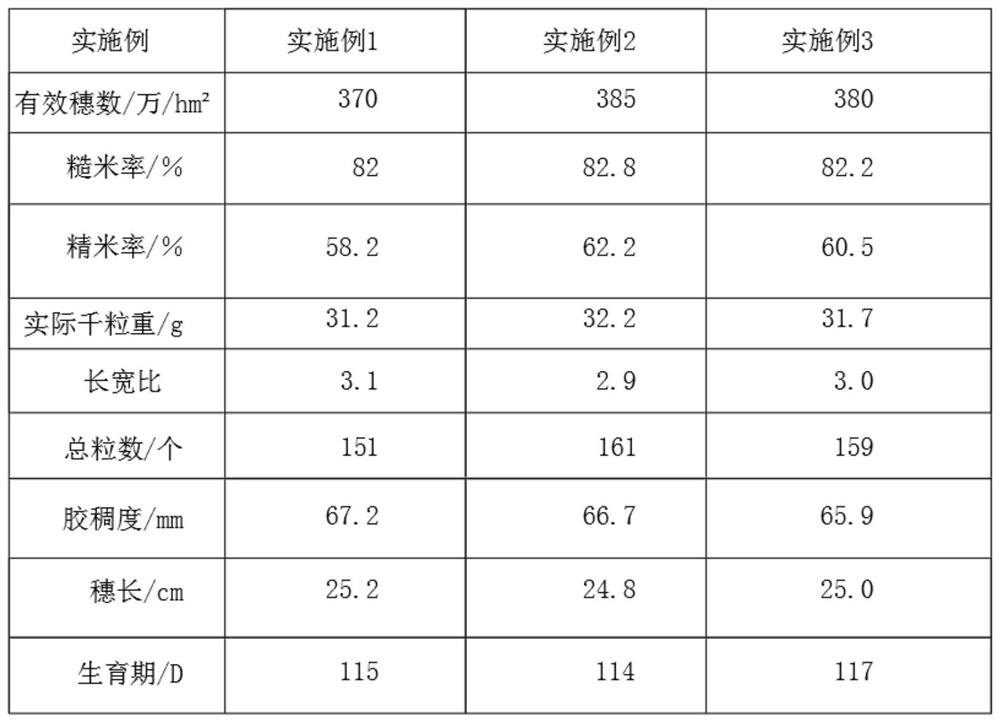

Dense and erect panicle gene and uses thereof

InactiveUS20110197305A1Increase productionImprove the immunityPeptide/protein ingredientsMicroorganismsPlant traitsPanicle

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI +1

Special compound fertilizer for desalted soil and capable of increasing rice yield

InactiveCN113480344AHead tidyGrout fastBio-organic fraction processingMagnesium fertilisersHumic acidEnvironmental geology

The invention relates to the technical field of fertilizer production, and discloses a special compound fertilizer used for desalted soil and capable of increasing the rice yield. The compound fertilizer is prepared from the following raw materials in parts by weight: 80 to 130 parts of biogas residue, 20 to 30 parts of biogas slurry, 50 to 70 parts of urea, 100 to 120 parts of fermented livestock manure, 40 to 50 parts of calcium hydrogen phosphate, 1 to 5 parts of brown sugar, 10 to 25 parts of silicon fertilizer, 20 to 30 parts of magnesium chloride, 10 to 20 parts of ferric chloride, 10 to 20 parts of zinc chloride, 15 to 25 parts of boron fertilizer, 5 to 10 parts of manganese molybdate, 30 to 50 parts of nitrogen, 30 to 50 parts of humic acid, 30 to 50 parts of potassium, 1 to 5 parts of chitooligosaccharide, 10 to 20 parts of borax, 6 to 10 parts of betaine, 5 to 8 parts of seaweed meal, 5 to 8 parts of glycerol, 3 to 6 parts of grass ash and 1 to 3 parts of wormcast. The rice produced by using the compound fertilizer disclosed by the invention is neat in ear head, quick in filling, full in grains and good in yellowing during ripening, can effectively promote early-stage and middle-stage growth of the rice, and is beneficial to later-stage filling and dry matter accumulation, so that the highest yield is obtained, and the rice produced by using the compound fertilizer can improve the utilization rate of the fertilizer.

Owner:何建国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com