ZnO modified SnO2-based perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve problems such as energy level mismatch, film quality reduction, and battery efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of ZnO modified SnO 2 A method for preparing a base perovskite solar cell, comprising the steps of:

[0034] Step ①: Mix the ZnO nanoparticle aqueous solution and ammonia water to make a ZnO precursor solution, and then filter it with a 0.22 μm PTFE filter head, wherein the mass fraction of ZnO nanoparticles in the ZnO nanoparticle aqueous solution is 20%, and the volume fraction of ammonia water is 50%, The volume ratio of ZnO nanoparticles aqueous solution and ammonia water is 1:25;

[0035] Spin-coat 30 μL of ZnO precursor solution on the surface of the conductive glass layer (ITO) and then anneal to form a 20nm-thick ZnO modified layer. The rotation speed is 5000rpm / 30s, spin-coating for 30s, the annealing temperature is 200°C, and the annealing time is 15 minutes;

[0036] Step ②: SnO 2 Nanoparticle aqueous solution mixed with ammonia water to make SnO 2 Precursor solution, and then filtered with 0.22μm PTFE filter head, in which SnO 2 SnO in nanoparticl...

Embodiment 2

[0058] see Figure 4 , the difference between this embodiment and embodiment 1 is that SnO 2 The thickness of the electron transport layer was 60 nm.

Embodiment 3

[0060] see Figure 5 , the difference between this embodiment and embodiment 1 is that SnO 2 The thickness of the electron transport layer was 40 nm.

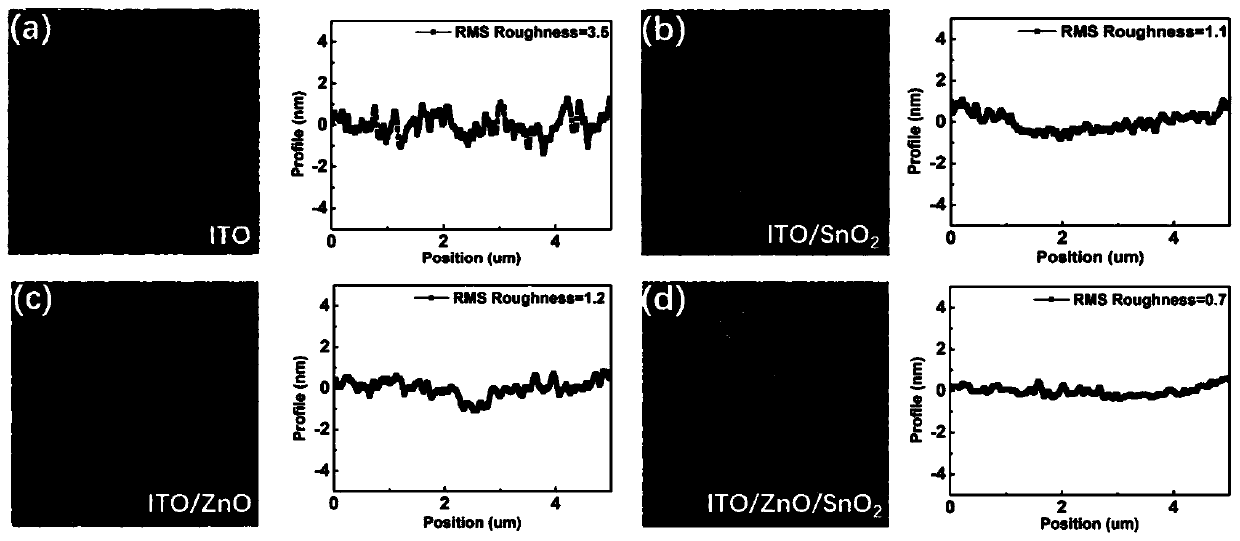

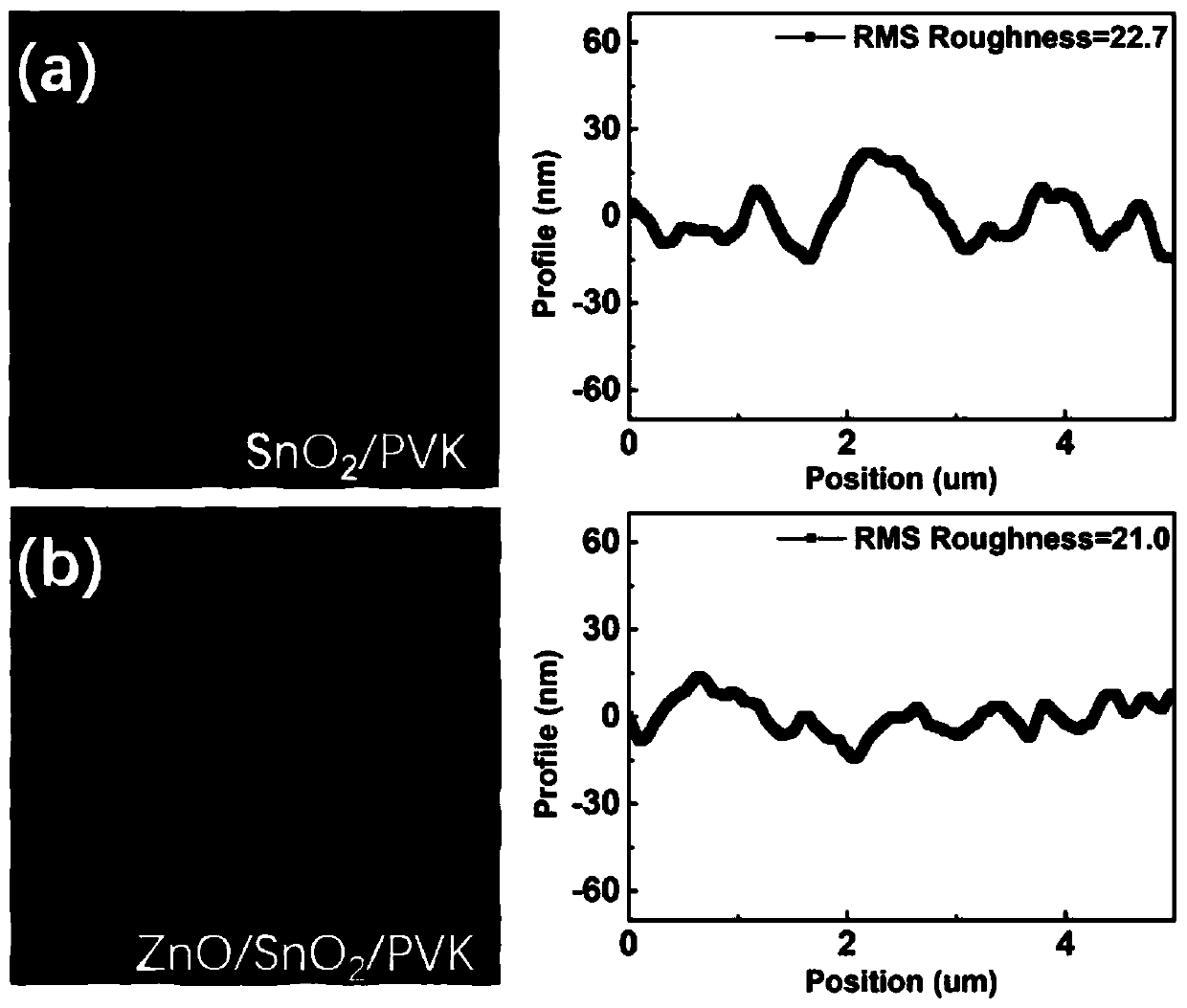

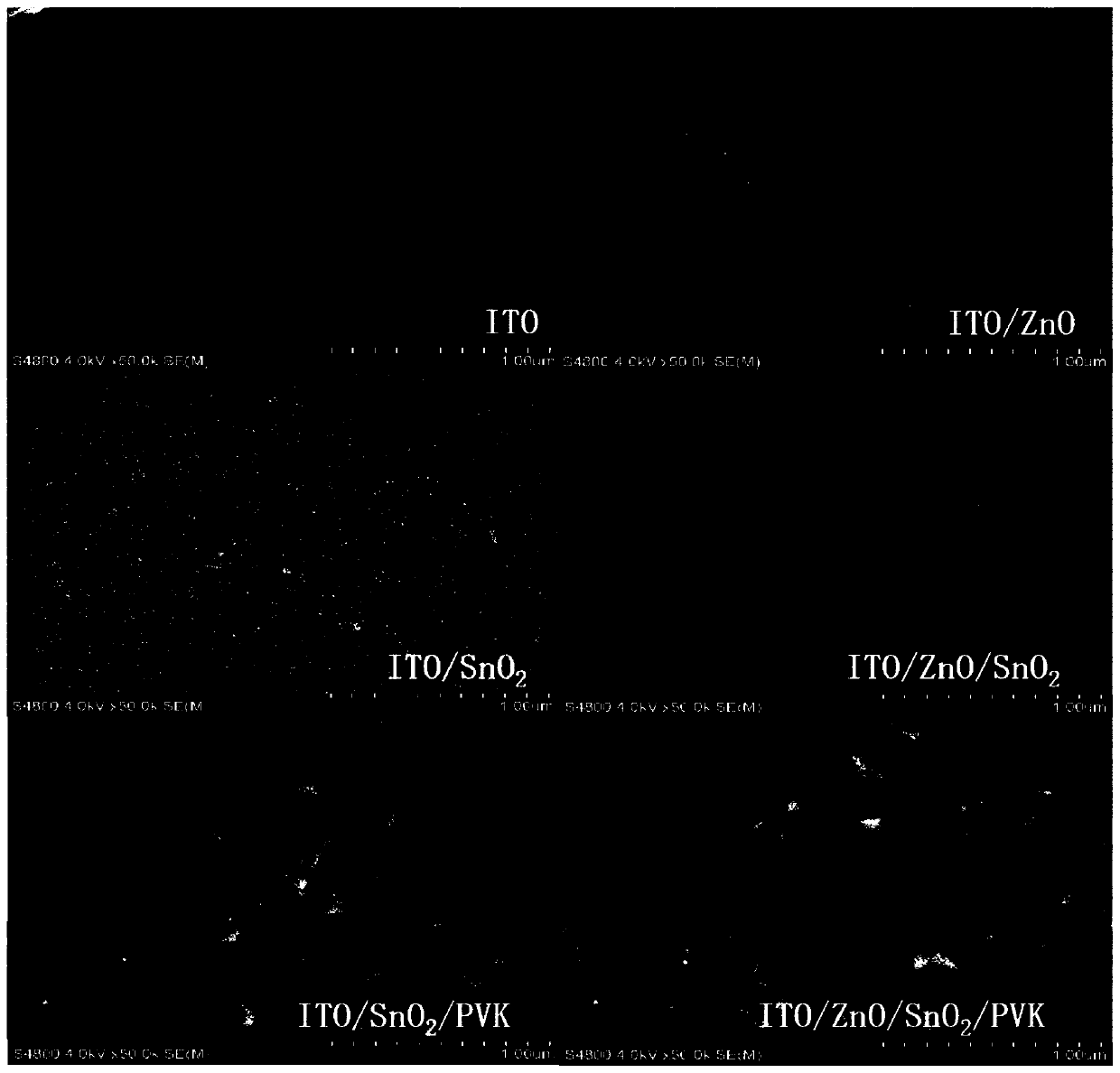

[0061] see image 3 d in and Figure 4 and Figure 5 , with SnO 2 With increasing thickness of the electron transport layer, SnO 2 The surface roughness of the electron transport layer did not change significantly, indicating that the ZnO modification layer and the SnO 2 The electron transport layer cooperates, when SnO 2 After the electron transport layer is spin-coated on the ZnO modified layer, it does not only fill the pits on the surface of the ZnO modified layer, but also acts on the surface of the SnO through the ZnO modified layer. 2 The surface of the electron transport layer is affected, and the effect is in the SnO 2 The case where the thickness of the electron transport layer is increased can also be clearly manifested.

[0062] see Figure 6 , the main diffraction peaks include 14.1°, 19.9°, 24.5°, 28.3° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com