Special compound fertilizer for desalted soil and capable of increasing rice yield

A compound fertilizer and soil technology, applied in organic fertilizers, inorganic fertilizers, excretion fertilizers, etc., can solve the problems of low fertilizer efficiency, single performance, simple components, etc. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

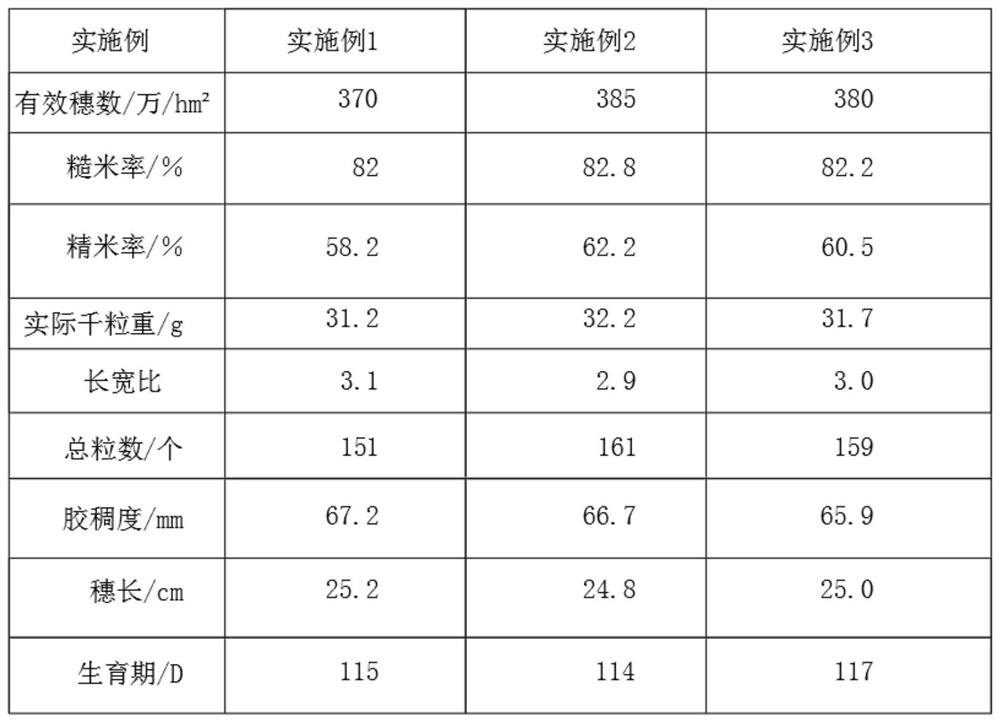

Embodiment 1

[0030] see figure 1 , a kind of special-purpose compound fertilizer that can increase rice output for desalination soil, comprises the following steps:

[0031] S1: 80 parts of biogas residue, 30 parts of biogas slurry, 70 parts of urea, 100 parts of fermented poultry manure, 40 parts of calcium hydrogen phosphate, 5 parts of brown sugar, 25 parts of silicon fertilizer, 30 parts of magnesium chloride, 20 parts of ferric chloride, 20 parts of zinc, 22 parts of boron fertilizer, 5 parts of manganese molybdate, 50 parts of nitrogen, 30 parts of humic acid, 50 parts of potassium, 1 part of chitooligosaccharides, 20 parts of borax, 6 parts of betaine, 8 parts of seaweed powder, 5 parts of glycerin, 6 parts of grass ash and 1 part of vermicompost;

[0032] S2: Raw material crushing, 80 parts of biogas residue obtained in S1, 100 parts of fermented poultry manure, 1 part of chitooligosaccharides, 20 parts of borax, 6 parts of betaine and 1 part of vermicompost were placed in a pulve...

Embodiment 2

[0042] see figure 1 , a kind of special-purpose compound fertilizer that can increase rice output for desalination soil, comprises the following steps:

[0043] S1: 105 parts of biogas residue, 25 parts of biogas slurry, 60 parts of urea, 110 parts of fermented poultry manure, 45 parts of calcium hydrogen phosphate, 3 parts of brown sugar, 17 parts of silicon fertilizer, 25 parts of magnesium chloride, 15 parts of ferric chloride, 15 parts of zinc, 20 parts of boron fertilizer, 7 parts of manganese molybdate, 40 parts of nitrogen, 40 parts of humic acid, 40 parts of potassium, 3 parts of chitooligosaccharides, 15 parts of borax, 8 parts of betaine, 7 parts of seaweed powder, 7 parts of glycerin, 5 parts of grass ash and 2 parts of vermicompost;

[0044] S2: Raw material crushing, 105 parts of biogas residue obtained in S1, 110 parts of fermented poultry manure, 3 parts of chitooligosaccharides, 15 parts of borax, 8 parts of betaine and 2 parts of vermicompost were placed in a...

Embodiment 3

[0054] see figure 1 , a kind of special-purpose compound fertilizer that can increase rice output for desalination soil, comprises the following steps:

[0055] S1: 100 parts of biogas residue, 30 parts of biogas slurry, 70 parts of urea, 99 parts of fermented poultry manure, 50 parts of calcium hydrogen phosphate, 5 parts of brown sugar, 15 parts of silicon fertilizer, 20 parts of magnesium chloride, 20 parts of ferric chloride, 20 parts of zinc, 15 parts of boron fertilizer, 10 parts of manganese molybdate, 50 parts of nitrogen, 30 parts of humic acid, 30 parts of potassium, 5 parts of chitooligosaccharides, 20 parts of borax, 10 parts of betaine, 8 parts of seaweed powder, 8 parts of glycerin, 6 parts of grass ash and 3 parts of vermicompost;

[0056] S2: raw material crushing, 100 parts of biogas residue obtained in S1, 99 parts of fermented poultry manure, 5 parts of chitooligosaccharides, 20 parts of borax, 10 parts of betaine and 3 parts of vermicompost were placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com