Handheld lubrication system for four-stroke engine

A four-stroke engine and lubrication system technology, applied in the direction of engine lubrication, engine components, valve accessories lubrication, etc., can solve problems such as lubrication of running parts that are not well guaranteed, oil burning, availability, etc., to achieve the effect of oil and gas separation Good, low lubricating oil loss, good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

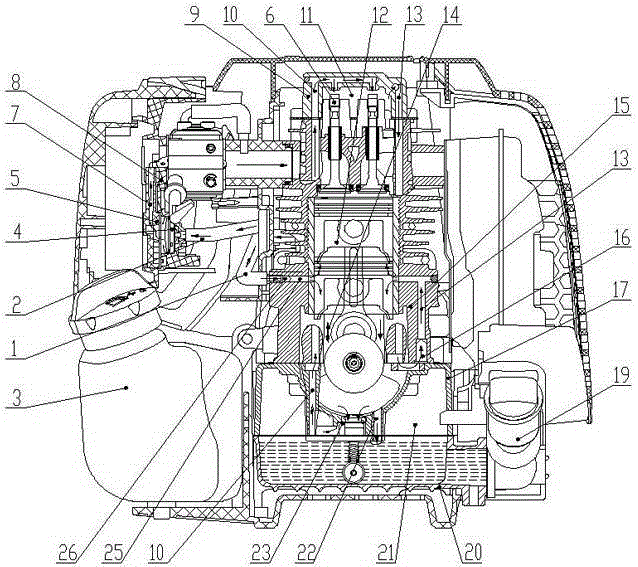

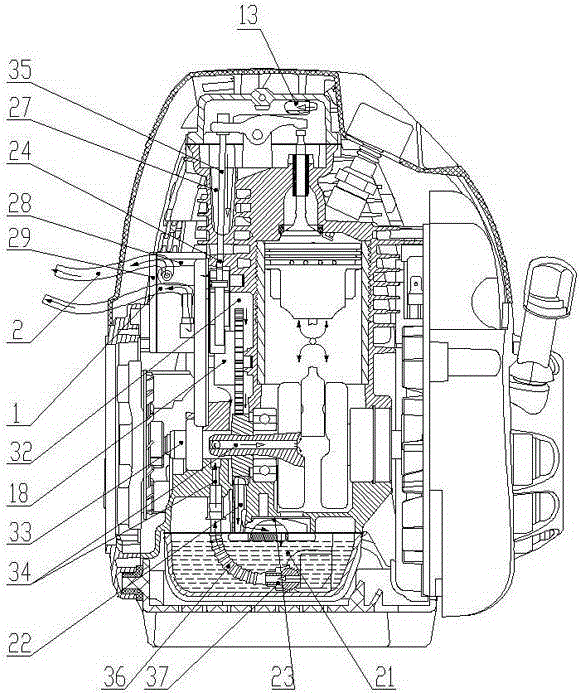

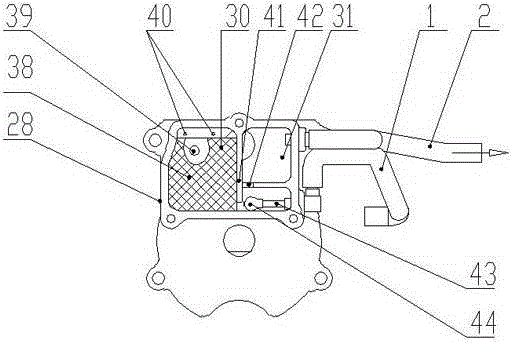

[0024] Figure 1 to Figure 5 Shown is a specific implementation of the lubrication system of a handheld four-stroke engine created by the present invention, which includes an oil sump 20 and a tank body 17 consisting of an oil storage chamber 21, and a crankshaft chamber consisting of a tank body 17 and a cylinder block 15 14. Rocker valve chamber 11 composed of cylinder block 15 and cylinder head cover 9, cam chamber 32 composed of cylinder block 15 and cam side cover 28, tappet chamber 27 attached to the side of cylinder block 15, air filter 8, fuel tank 3 , The oil pan 20 is connected to the organic oil port 19, the cylinder block 15 is provided with a piston assembly 12, the crank chamber 14 is provided with a crankshaft connecting rod assembly 33, the rocker arm valve chamber 11 is provided with a rocker arm valve assembly 6, and a tappet chamber 27 A tappet assembly 35 is provided, a cam assembly 18 is provided in the cam chamber 32, and an oil suction passage 34 connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com