Liquefied natural gas gasifier detachably connected with internal and external heat exchange sheets

A technology of liquefied natural gas, disassembly and connection, which is applied in the field of liquefied natural gas transportation, can solve the problems of poor gasification effect, non-adjustable gas transmission speed, etc., and achieve good heat absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

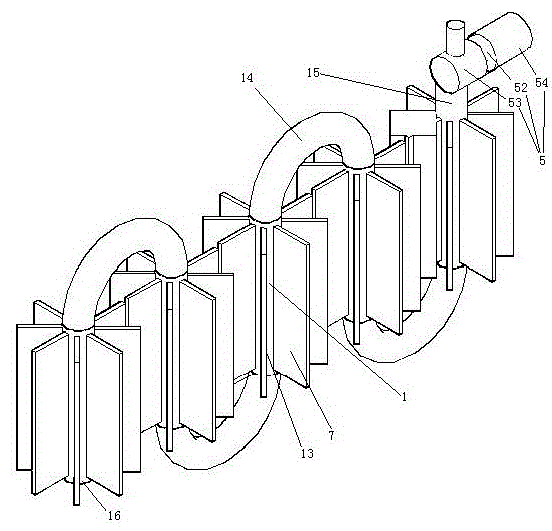

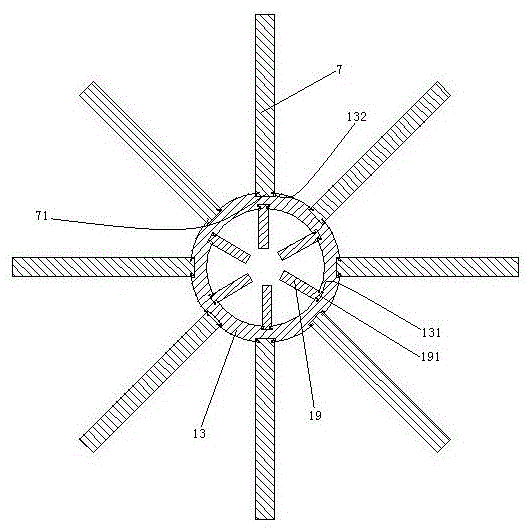

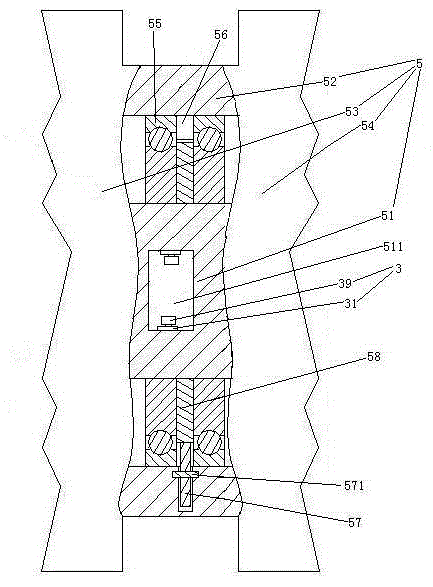

[0033] Embodiment one, see figure 1 , a liquefied natural gas vaporizer detachably connected with internal and external heat exchange fins, including a vaporization pipe 1 and a delivery pump 5 . The gasification tube 1 is a circular tube. The chemical tube 1 includes several gasification sections 13 and bending sections 14 . Specifically, there are four gasification sections 13 and four bending sections 14 . The gasification section 13 has a linear structure, that is, a straight pipe. The gasification section 13 and the bending section 14 are arranged at intervals so that the gasification tube 1 forms a folded structure. The outer surface of the gasification section 13 is provided with several outer heat exchange fins 7 . The outer heat exchange fins 7 are distributed along the circumference of the gasification section 13 . Delivery pump 5 is existing structure. The feed pump 5 includes a pump housing 52 . Both ends of the pump casing 52 are provided with a delivery pu...

Embodiment 2

[0044] Embodiment two, the difference with embodiment one is:

[0045] see Figure 8 , each gasification section 13 is provided with a self-cutting switch 9 for dumping. All pouring self-cutting switches are connected in series for controlling the motor 54 of the delivery pump 5 to stop.

[0046] The tilt self-cutting switch 9 includes a shell 91 and a connecting pin 92 . The shell 91 is fixedly connected with the gasification section 13 .

[0047] see Figure 9 , The tilt self-disconnecting switch 9 also includes a power-disconnecting spring 93 , a conductive sheet 94 , a weight guide cavity 95 , a weight 96 , a swing arm 97 and a barb 98 .

[0048] The shell 91 is made of insulating material, specifically made of plastic. The housing 91 is provided with an assembly cavity 911 . A recess 915 is formed in the middle of the bottom wall of the assembly cavity 911 .

[0049] There are two connecting pins 92. The two connecting pins 92 are distributed along the left and ri...

Embodiment 3

[0058] Embodiment three, the difference with embodiment two is:

[0059] see Figure 12 , A number of outlet holes 11 are provided on the peripheral surface of the outlet end 16 of the gasification tube. A tube base 12 is connected to the outer end of the air outlet hole 11 . The tube base 12 and the outlet end 16 of the gasification tube are welded together. The inner pipe 4 is pierced in the air outlet hole 11 . The inner end of the inner tube 4 is provided with a flange 41 . The inner tube 4 passes through the tube base 12 and then passes into and out of the trachea 2 .

[0060] see Figure 13 , the flange 41 is hooked on the inner peripheral surface of the outlet end 16 of the gasification tube. The flange 41 and the inner peripheral surface of the outlet end 16 of the gasification tube are only connected together by abutting. The junctions of the pipe base 12 , the inner pipe 4 and the outlet pipe 2 are welded together to form a weld 6 . The weld seam 6 seals and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com