Coal rock upward borehole gas parameter measurement method

A measurement method and gas technology, applied to the measurement of gas parameters in coal and rock upward drilling, and in the field of measurement of gas parameters in coal and rock upward drilling, can solve the problems of easy subsidence of drilling holes and influence on the measurement of gas parameters, and achieve the purpose of suppressing drilling Hole collapse, ensuring the effect of gas drainage, quick disassembly and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further clearly and completely described below in conjunction with specific embodiments.

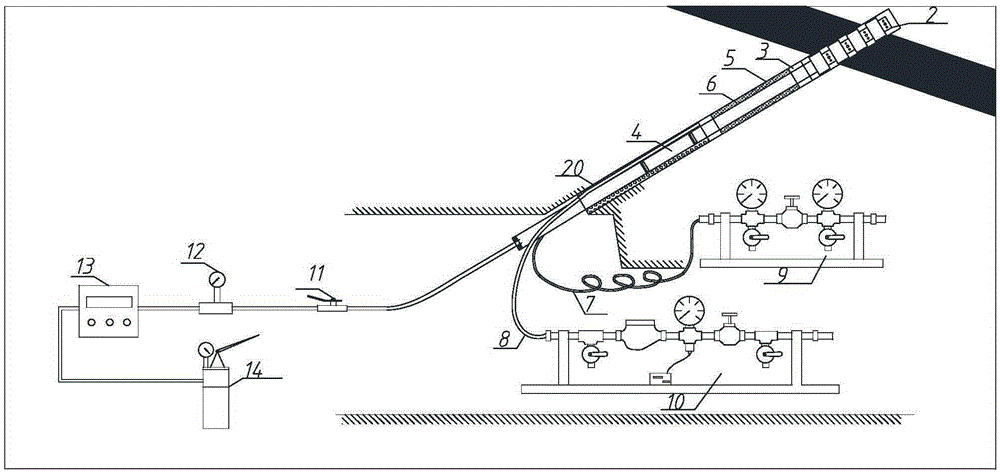

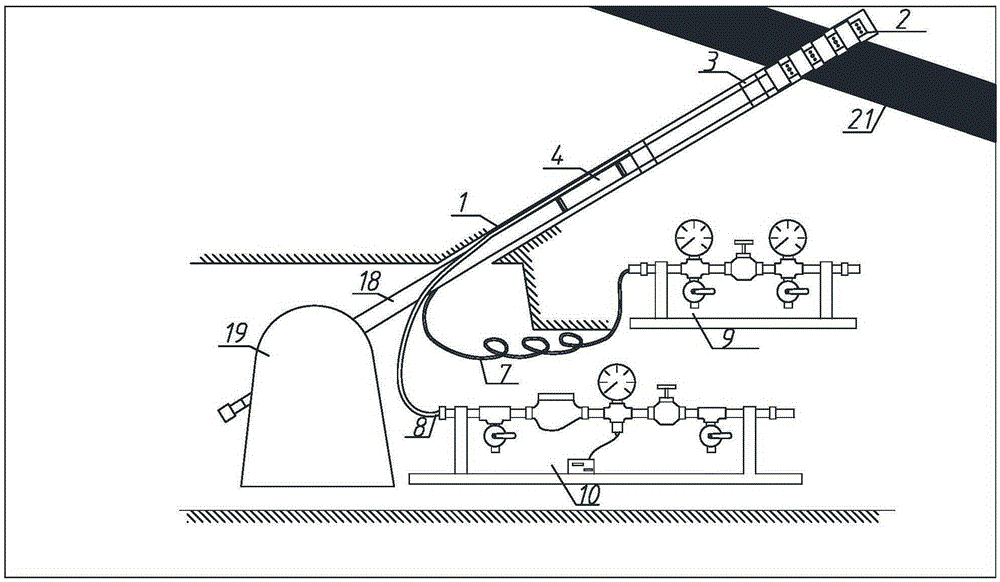

[0032] The system used in the gas parameter determination method of coal rock uphole drilling in the present invention, such as figure 1 As shown, it mainly includes a detection device, a blocking device and a measuring device.

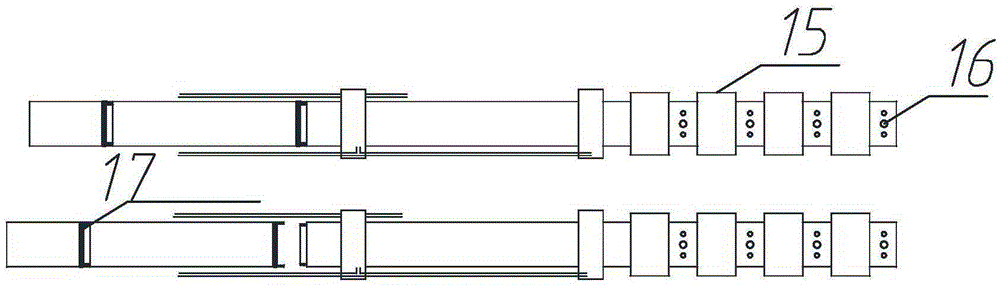

[0033] The detection device includes the first pipe body 18, the second pipe body 4 and the third pipe body 2 connected in sequence, wherein the third pipe body extends into the bottom of the borehole 1, and the first pipe body 18 is located at the outermost side of the borehole , the first pipe body 18 can be a drill pipe in the prior art, etc., and the two ends of the second pipe body 4 are provided with threads, and the two ends are respectively matched with the structures in the first pipe body and the third pipe body, which can realize Quick detachable connections such as image 3 As shown, in order to connect more tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com