Preparation method of nanoscale micro structure

A technology of nanoscale microstructure and carbon nanotube structure, which is applied in the field of preparation of nanoscale microstructures, can solve the problems of long time, complicated process, and difficulty in achieving nanoscale dimensions, and achieves simple preparation method and easy industrialization. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

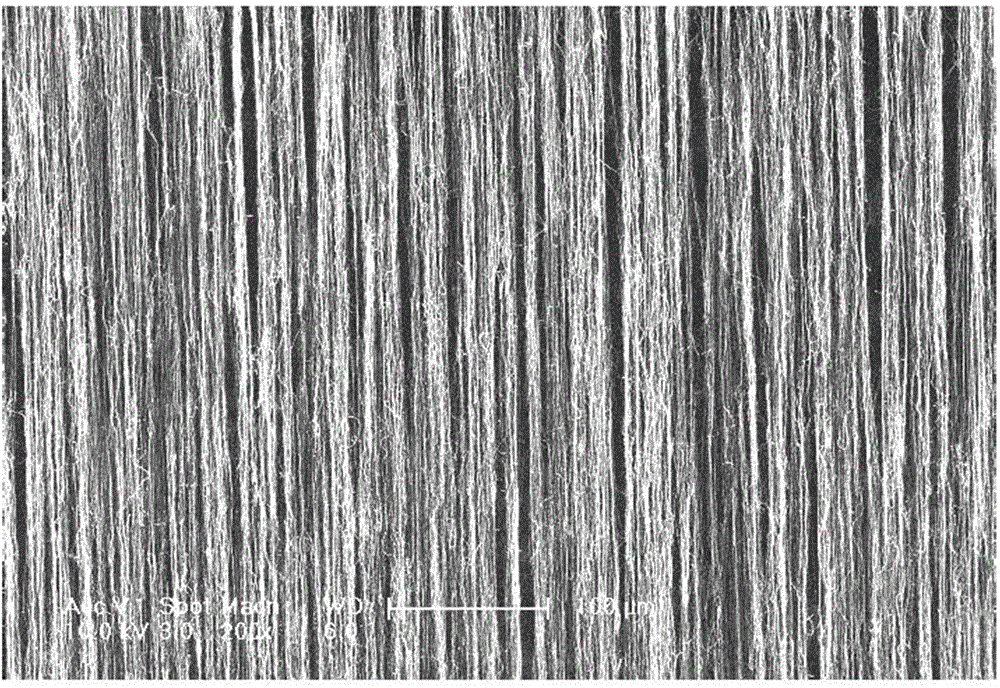

[0019] Various embodiments of the nanoscale microstructure and its preparation method will be further described in detail below in conjunction with the accompanying drawings.

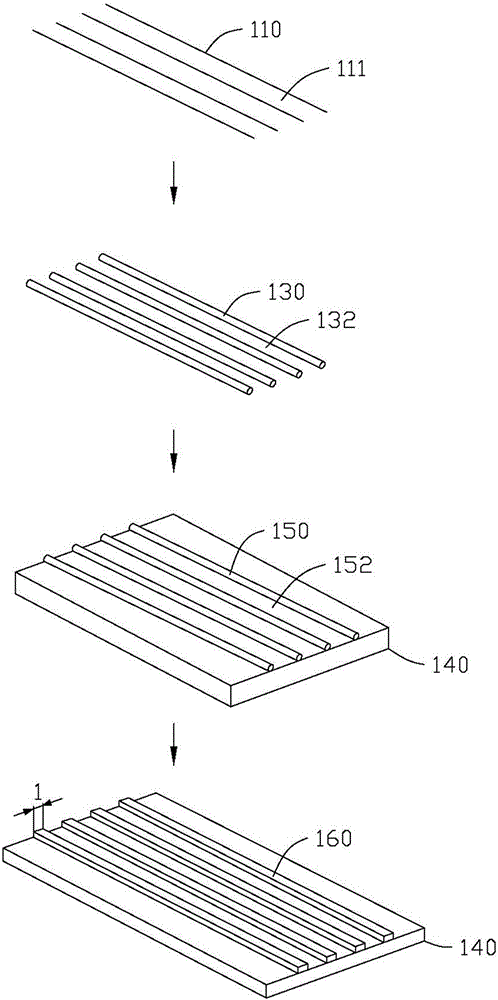

[0020] see figure 1 as well as figure 2 , the first embodiment of the present invention provides a method for preparing a nanoscale microstructure, which includes the following steps:

[0021] Step S10, providing a carbon nanotube structure 110, the carbon nanotube structure 110 comprising a plurality of carbon nanotubes arranged in an orderly manner;

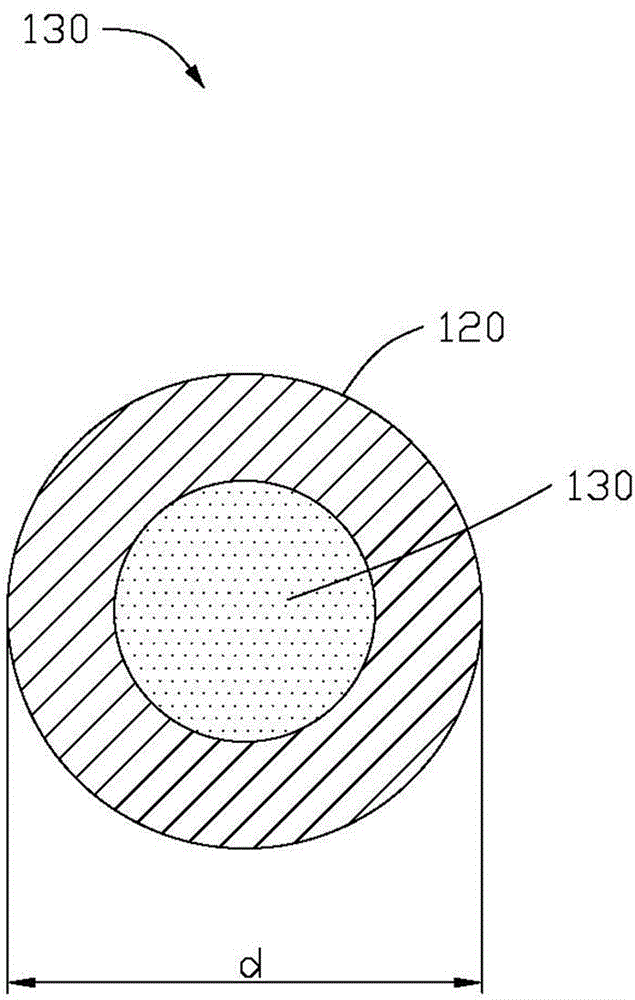

[0022] Step S20, setting a prefabricated layer 120 on the surface of the carbon nanotube structure 110, so that the thickness of the prefabricated layer 120 on the surface of each carbon nanotube is 3 nanometers to 50 nanometers, so as to obtain a carbon nanotube composite structure 130;

[0023] Step S30, disposing the carbon nanotube composite structure 130 on the surface of a substrate 140 to form a mask layer 150, the mask layer has a plurality of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com