Silicon wafer transmission control method and system

A transmission control and silicon wafer technology, which is applied in the field of silicon wafer transmission control methods and systems, can solve problems affecting yield, silicon wafer pollution, transmission cavity occupation, etc., and achieves the effect of eliminating waiting time and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

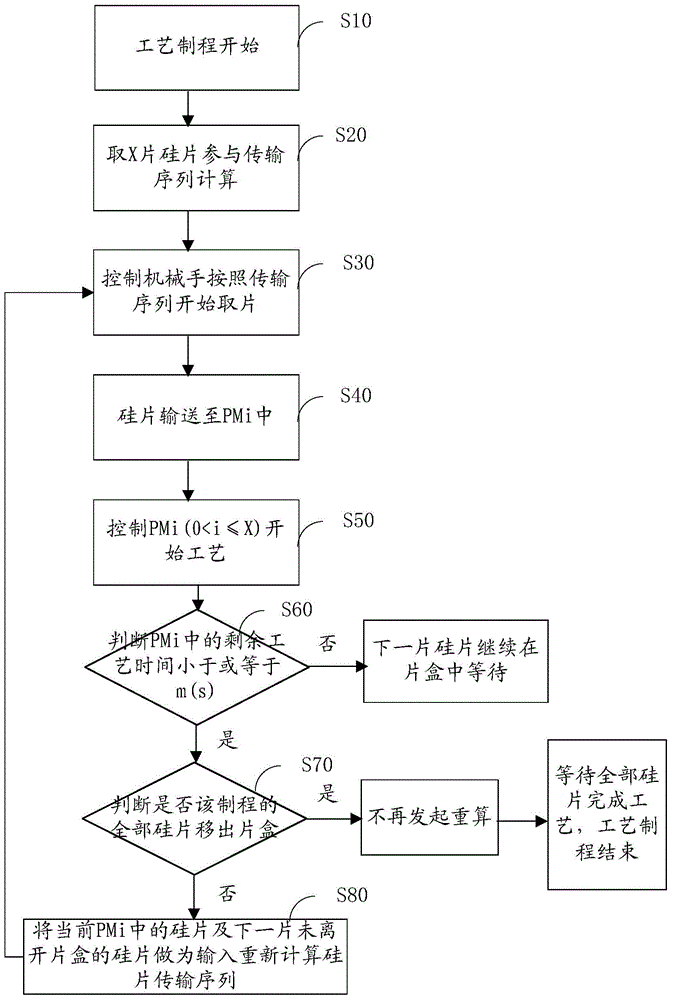

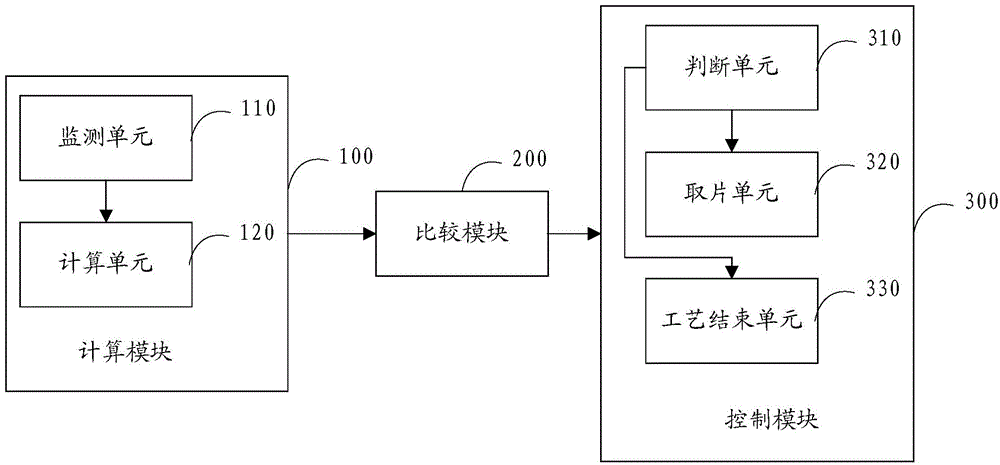

[0042] The silicon wafer transmission control method and system provided by the embodiments of the present invention will be described below with reference to the accompanying drawings.

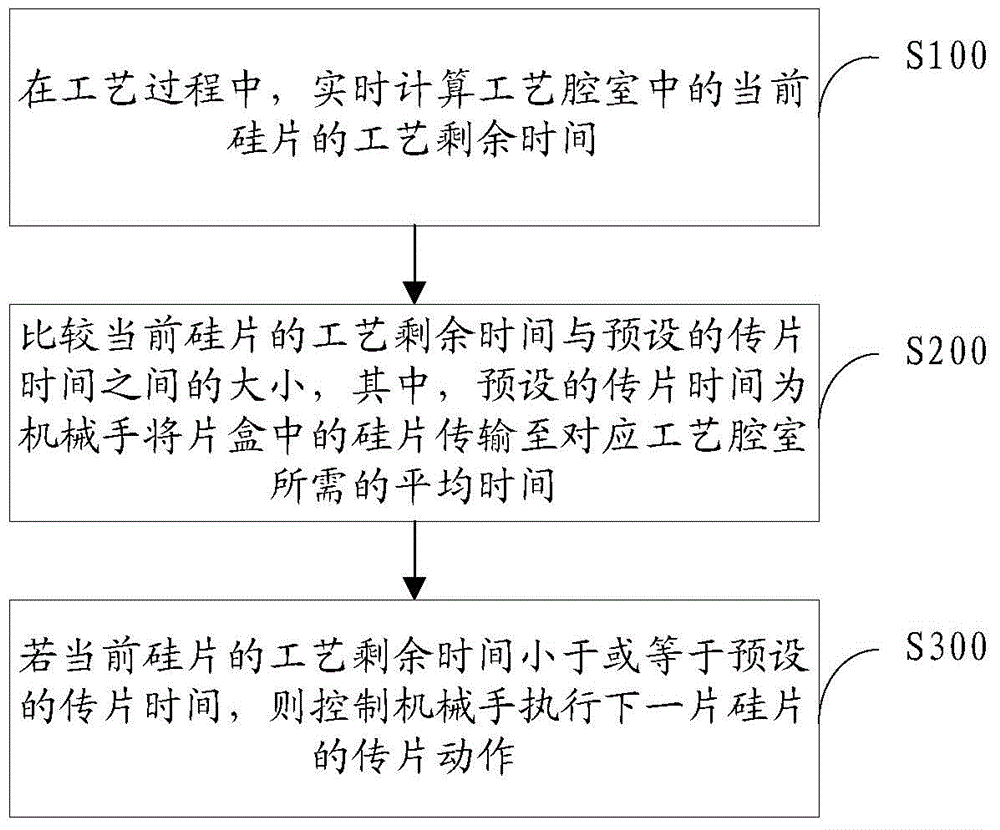

[0043] see figure 1 , the silicon wafer transmission control method provided by the present invention, comprises the following steps:

[0044] S100, during the process, calculate the remaining process time of the current silicon wafer in the process chamber in real time;

[0045] S200, comparing the remaining time of the current silicon wafer process with the preset film transfer time, wherein the preset film transfer time is the average time required for the robot to transfer the silicon wafers in the cassette to the corresponding process chamber ;

[0046] S300, if the remaining process time of the current silicon wafer is less than or equal to the preset wafer transfer time, control the manipulator to execute the wafer transfer action of the next silicon wafer.

[0047] The remaining ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com