Polysilicon array substrate manufacturing method, polysilicon array and display panel

A technology of an array substrate and a manufacturing method, which is applied in the display field, can solve the problems of difficulty in manufacturing and complicated manufacturing process of a polysilicon array substrate, and achieve the effect of reducing the difficulty of manufacturing and simplifying the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

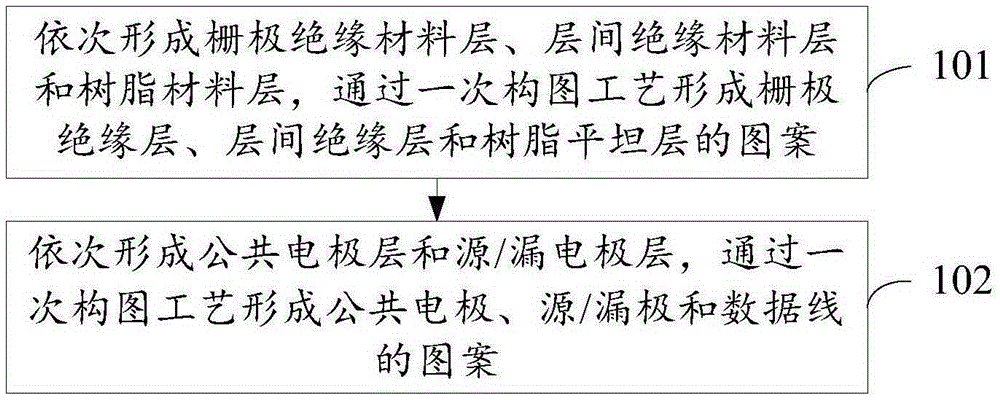

[0030] see figure 1 , the method for manufacturing a polysilicon array substrate provided by an embodiment of the present invention includes:

[0031] In step 101, a gate insulating material layer, an interlayer insulating material layer and a resin material layer are sequentially formed, and the patterns of the gate insulating layer 16, the interlayer insulating layer 18 and the resin flat layer 19 are formed through a patterning process; in this step, Form a layer of gate insulating material, form a layer of interlayer insulating material above the layer of gate insulating material, form a layer of resin material on the layer of interlayer insulating material, and use a patterning process to form the gate insulating layer 16, Patterns of the interlayer insulating layer 18 and the resin flat layer 19 .

[0032] In step 102, a common electrode layer and a source / drain electrode layer are sequentially formed, and the patterns of the common electrode 20, the source / drain electr...

Embodiment 2

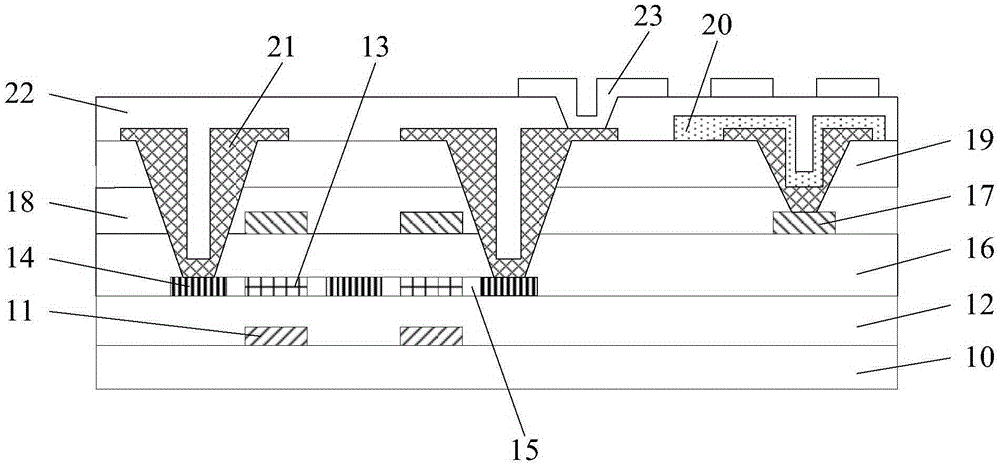

[0041] see Figure 5 , the specific implementation method of step 101 and step 102 in the first embodiment will be described below, wherein, step 101 can be specifically refined into step 1011 and step 1012, and step 102 can be specifically refined into step 1021-step 1024, and the specific content is as follows :

[0042] Step 1011, sequentially forming a gate insulating material layer, an interlayer insulating material layer and a resin material layer.

[0043] Step 1012: Perform an etching process on the resin material layer, the interlayer insulating material layer, and the gate insulating material layer by using a mask process, and form a first pass on the resin material layer, the interlayer insulating material layer, and the gate insulating material layer. hole and the second via hole to obtain the pattern of the resin planar layer 19, the interlayer insulating layer 18 and the gate insulating layer 16; wherein, the first via hole penetrates the resin material layer, t...

Embodiment 3

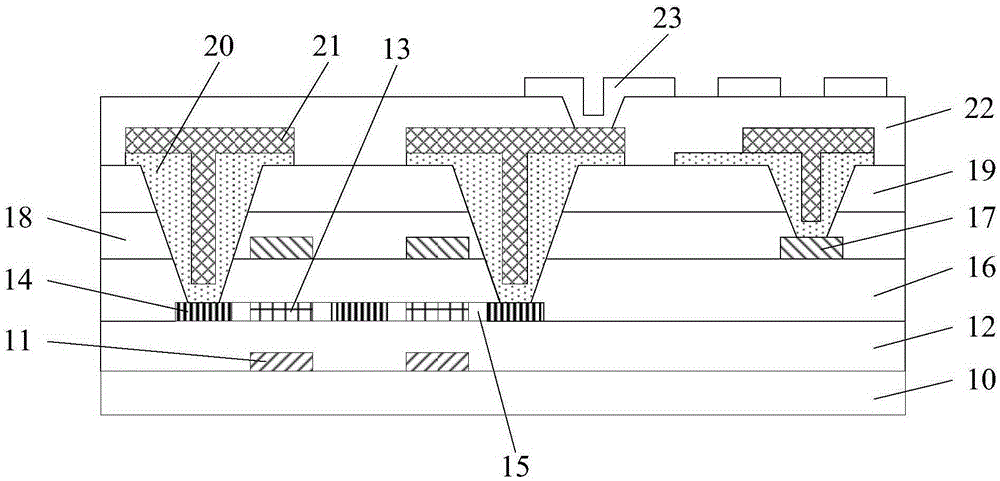

[0051] see Image 6 , in the polysilicon array substrate, it also includes a base substrate 10, a light shielding layer 11, an active layer 13, an ohmic contact layer 14, a lightly doped drain layer 15, a gate and a gate line 17, a passivation layer 22 and a pixel electrode 23 and other structures, in order to make the above structure, before step 101 in the first embodiment, also include step 103-step 105, after step 102, also include step 106 and step 107, the specific content of step 103-step 107 is as follows:

[0052] Step 103 , forming a light-shielding material layer on the base substrate 10 , and forming a pattern of the light-shielding layer 11 through one patterning process.

[0053] Step 104 , forming an active material layer on the light shielding layer 11 and the base substrate 10 , and forming a pattern of the active layer 13 through a patterning process.

[0054] In step 105, a gate electrode layer is formed on the active layer 13, and the pattern of the gate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com