Inversion multijunction solar cell chip of integration bypass diode and preparation method thereof

A technology of multi-junction solar cells and bypass diodes, applied in diodes, circuits, photovoltaic power generation, etc., can solve the problem that high-current batteries cannot realize the integration of bypass diodes, and achieve the effect of reducing battery weight and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

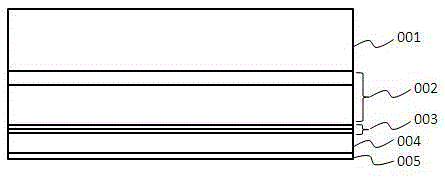

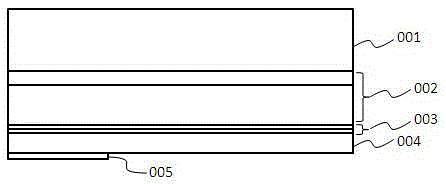

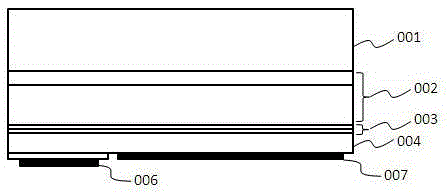

[0032] Such as figure 1 As shown, a flip-chip grown multi-junction solar cell epitaxial wafer is provided, and its structure includes: an epitaxial substrate 001, an n / p photoelectric conversion layer 002, a p / n tunnel junction 003, a bypass diode structure n-type layer 004, and a p type layer 005, wherein the n-type layer of the n / p photoelectric conversion layer 002 is used as the emission region and grown on the epitaxial substrate 001, and the p-type layer is used as the base region and grown on the n-type layer, p / n The tunnel junction 003 is grown on the p-type layer of the photoelectric conversion layer 002, the bypass diode n-type layer 004 is grown on the p / n tunnel junction 003 with a thickness of 3 μm, and the bypass diode p-type layer 005 is grown on the n Type layer 004, with a thickness of 50nm, the photoelectric conversion layer 002 also includes a window layer on the upper surface of the n-type layer, and a back field layer on the lower surface of the p-type la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com