Electric driver and air vehicle and ship applying same

An electric drive, aircraft technology, applied in the direction of electric power device, electromechanical device, power device, etc., can solve the problem of partial cancellation of output torque, and achieve the effect of more power, heat dissipation, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 (electric drive device)

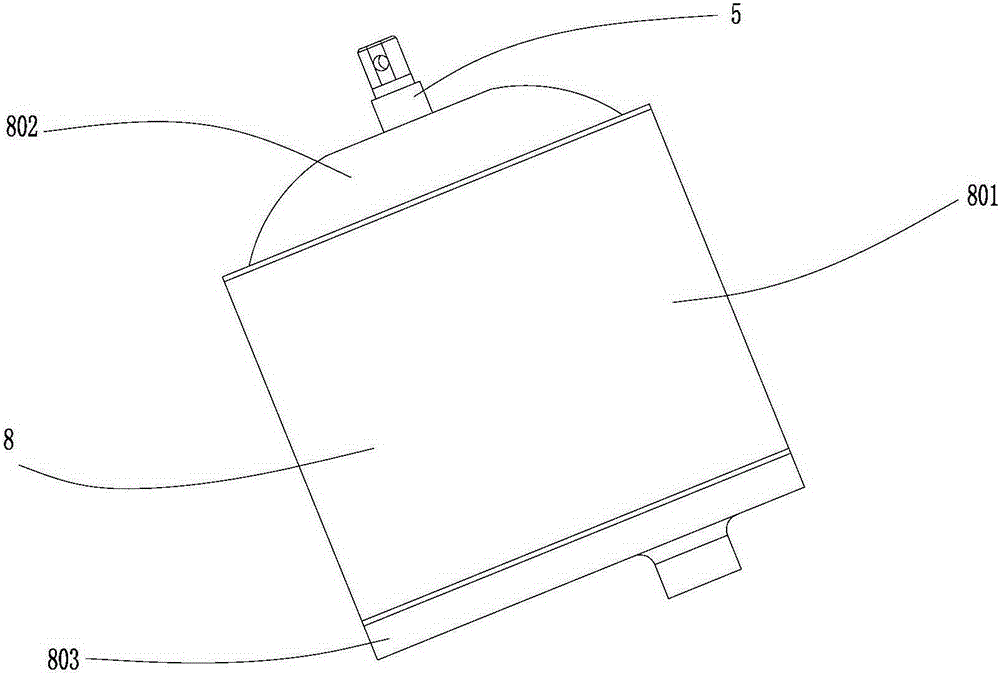

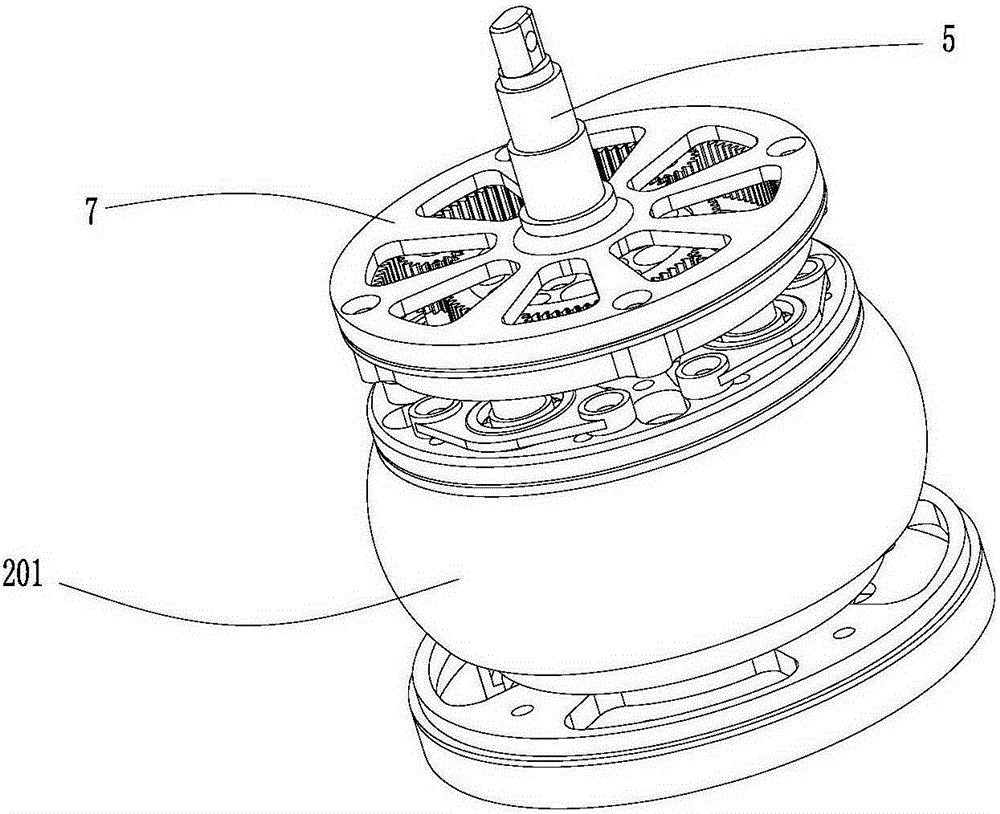

[0053] Such as Figure 1-Figure 8 As shown, the electric drive device of this embodiment includes: a first rotor system (inner rotor system 1), a second rotor system (outer rotor system 2), a separator 3, a synchronous output system 4, a motor output shaft 5, a first Connecting seat 6, second connecting seat 7, casing 8, braking system 9.

[0054] Such as Figure 7 As shown, the inner rotor system 1 includes an inner rotor 101 and an inner stator 102 arranged coaxially; the inner rotor 101 includes an inner shaft 105 and an inner magnet, and the inner shaft 105 is fixedly installed in a mounting hole on the base 803 through a bearing, and the inner magnet is fixed It is arranged outside the inner rotating shaft 105; the inner stator 102 is arranged outside the inner magnet; the partition 3 is arranged outside the inner stator 102, and the bottom of the partition 3 is screwed to the base 803.

[0055] Such as Figure 7 As shown,...

Embodiment 2

[0063] Embodiment 2 (electric drive device)

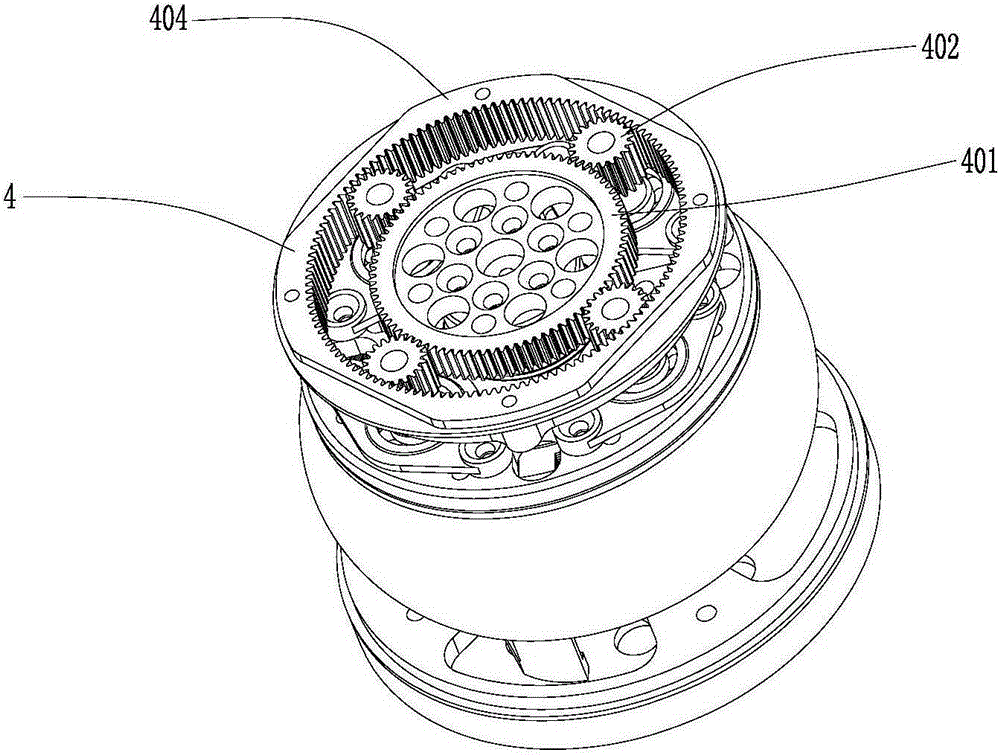

[0064] The difference between this embodiment and embodiment 1 is: as Figure 9 As shown, the first rotor 101 is located outside the first stator 102; the first rotor 101 drives the ring gear 404 to rotate; the second rotor 201 drives the planetary gear 402 to rotate around the sun gear 401 through the planet carrier 403; the motor output shaft 5 is connected to the sun gear Wheel 401 is fixedly connected.

Embodiment 3

[0065] Embodiment 3 (electric drive device)

[0066] Such as Figure 10 As shown, in this embodiment, the first rotor 101 drives the ring gear 404 to rotate; the second rotor 201 drives the planetary gear 402 to rotate around the sun gear 401 through the planet carrier 403 ; the motor output shaft 5 is fixedly connected to the sun gear 401 . The difference between this embodiment and Embodiment 2 is that: the first rotor 101 is located inside the first stator 102 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com