Pharmaceutical composition for weight reduction or metabolic syndrome treatment

A technology of metabolic syndrome and composition, which is applied in the direction of drug combination, metabolic disease, pharmaceutical formula, etc., and can solve the problems such as no reports of orlistat or selistat combined with rosiglitazone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

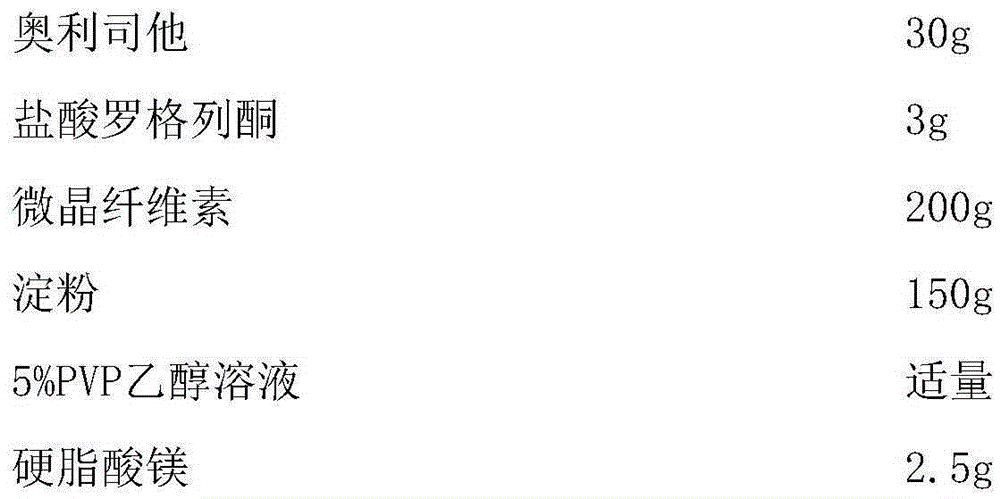

[0013] Embodiment 1: the preparation of compound tablet

[0014]

[0015] Preparation Process:

[0016] 1) Weigh orlistat, rosiglitazone hydrochloride, starch, and microcrystalline cellulose in the prescribed amount and mix uniformly;

[0017] 2) In addition, add an appropriate amount of 5% PVP ethanol solution to the mixed powder, mix evenly, make a soft material, pass through a 18-mesh sieve to make wet granules, and dry at 45°C. The moisture content of the dry granules should be controlled below 1.0%;

[0018] 3) Sorting through a 20-mesh sieve, mixing with magnesium stearate, and pressing into tablets.

Embodiment 2

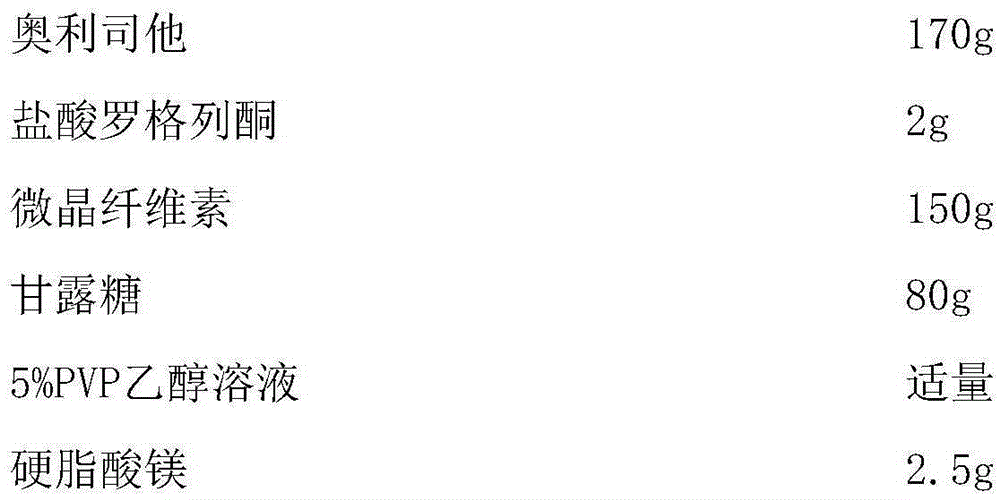

[0019] Embodiment 2: the preparation of compound tablet

[0020]

[0021] Preparation Process:

[0022] 1) Weigh orlistat, rosiglitazone hydrochloride, mannitol, and microcrystalline cellulose in the prescribed amount and mix uniformly;

[0023] 2) In addition, add an appropriate amount of 5% PVP ethanol solution to the mixed powder, mix evenly, make a soft material, pass through a 18-mesh sieve to make wet granules, and dry at 50°C. The moisture content of the dry granules should be controlled below 1.0%;

[0024] 3) Sorting through a 20-mesh sieve, mixing with magnesium stearate, and pressing into tablets.

Embodiment 3

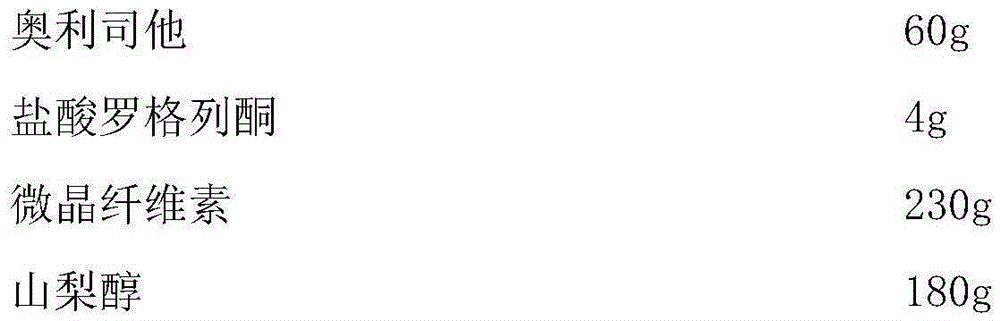

[0025] Embodiment 3: the preparation of compound tablet

[0026]

[0027]

[0028] Preparation Process:

[0029] 1) Orlistat, rosiglitazone hydrochloride, mannitol, sorbitol, and microcrystalline cellulose were weighed and mixed uniformly;

[0030] 2) In addition, add an appropriate amount of 5% PVP ethanol solution to the mixed powder, mix evenly, make a soft material, pass through a 18-mesh sieve to make wet granules, and dry at 50°C. The moisture content of the dry granules should be controlled below 1.0%;

[0031] 3) Sieve through a 20-mesh sieve, mix with magnesium palmitate stearate, and press into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com