Frame type hydraulic machine guiding structure special for hot press forging of high-speed rail part

A guiding structure and frame-type technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve problems such as bloated mechanism, high manufacturing cost, and inconvenient maintenance in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

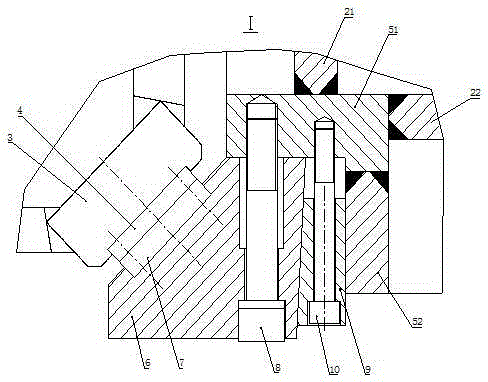

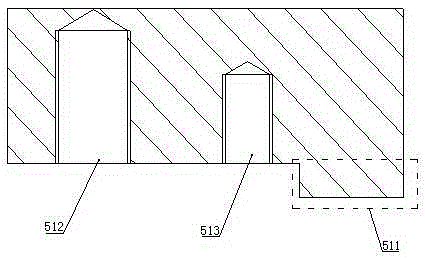

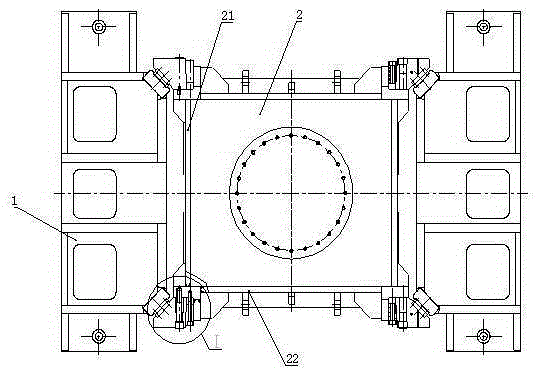

[0012] Such as figure 1 , 2 As shown, it includes a pair of frame-type uprights 1, and a slider 2 arranged between the pair of frame-type uprights 1, and a wedge-type guide rail assembly is arranged between the four corners of the slider 2 and the uprights 1 on both sides. The wedge guide rail assembly includes guide rail 3, guide rail side wear plate 4, adjustment seat, adjustment block 6, slider side wear plate 7, adjustment block locking screw 8, wedge block 9 and wedge block locking screw 10, wherein: The guide rail 3 is installed on the inner side of the column 1. The angle between the guide surface of the guide rail 3 and the longitudinal panel 21 and the transverse panel 22 of the slider 2 is 45°. The guide surface of the guide rail 3 has an inlay extending along the long axis of the guide rail groove, the guide rail side wear plate 4 is fixed in the mosaic groove.

[0013] The four corners of the slide block 2 are provided with a right-angle notch, and the right-angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com