A kind of sulfolane purification and regeneration process

A purification process, the technology of sulfolane, applied in the direction of organic chemistry, etc., can solve the problems of low dechlorination ability, large amount of regenerant consumption and discharge, and discharge of regenerant consumption, so as to achieve high resin utilization efficiency, fast regeneration speed and less washing water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

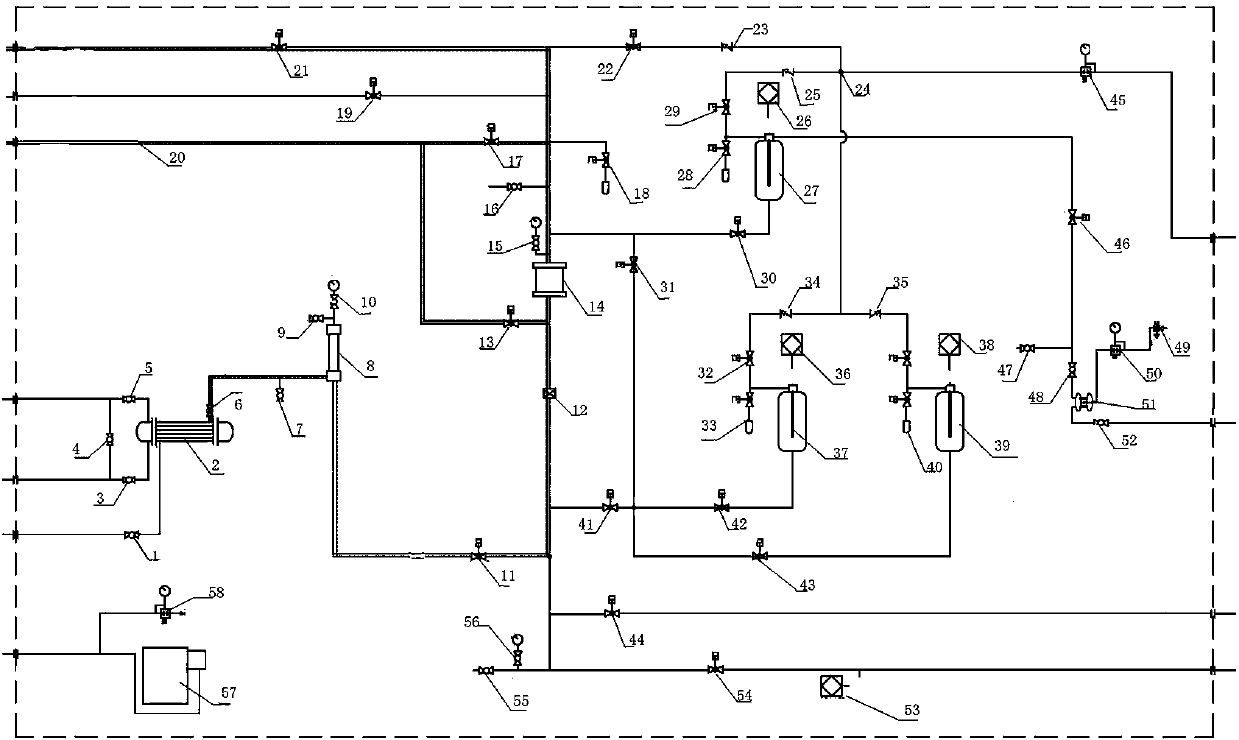

[0031] A sulfolane purification and regeneration process includes a sulfolane purification process and a resin bed regeneration process. The sulfolane purification process includes outputting the sulfolane that needs to be purified from a sulfolane stock tank into a cold heat exchanger for constant temperature treatment and then entering a security filter. The resin bed regeneration process includes the sulfolane entering the security filter into the shallow high-efficiency ion exchange resin bed for purification, and the purified sulfolane is transported to the purification sulfolane tank.

[0032] The sulfolane purification process further includes a resin bed residual sulfolane removal process, a purified water tank replenishing process, and a sulfolane recovery tank emptying process.

[0033] The resin bed residual sulfolane removal process includes pressurizing the nitrogen in the nitrogen generator to the shallow high-efficiency ion exchange resin bed to remove the sulfolane r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com