Composite structure failure prediction analytical method

A composite material and failure prediction technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of weakening the mechanical properties of the matrix and fibers, complex failure process and degradation behavior of composite materials, etc., to achieve the effect of accurate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

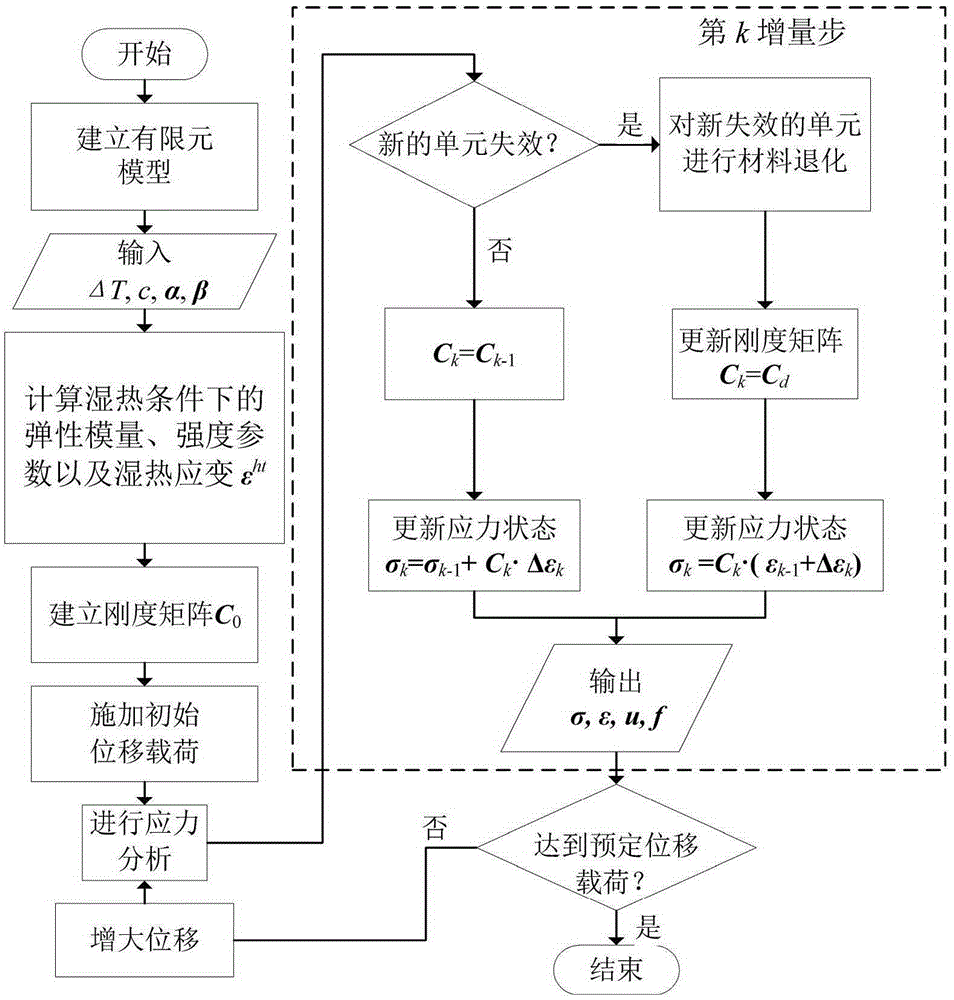

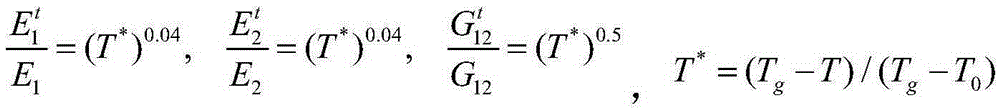

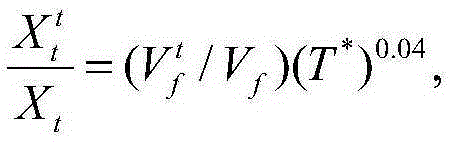

Method used

Image

Examples

Embodiment 1

[0065] Example 1: Tensile failure analysis of a typical composite orifice structure A typical composite orifice is made of T300 grade carbon fiber reinforced epoxy resin composite material, and the layup sequence is [45 / -45 / 0 / -45 / 0 / 45 / 0 / 45 / -45 / 0 / -45 / 45 / 90 / 45 / -45 / 0 / 45 / -45 / 90 / 0]s, single layer thickness is 0.12mm. Material fiber volume fraction V f It is about 63%, the glass transition temperature is about 260°C, the thermal expansion coefficients are α1=0.25×10-6 / K, α2=32.6×10-6 / K, and the wet expansion coefficients are β1=0, β2=0.6 ×10-6, γ is set to 10-6, and, based on the existing material degradation coefficient calculation method, the calculation of each degradation coefficient is as follows:

[0066] d ft = 0.00874; d fc = 0.0693; d fm1 = 0.061; d fm2 =0.18

[0067] 1. According to the geometric parameters of the composite orifice plate structure, a three-dimensional finite element model of the structure is established in the finite element software ABAQUS, and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com