Automobile wire

A wire and automobile technology, applied in the field of automobile wires, can solve the problems of poor wear resistance and achieve stable scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

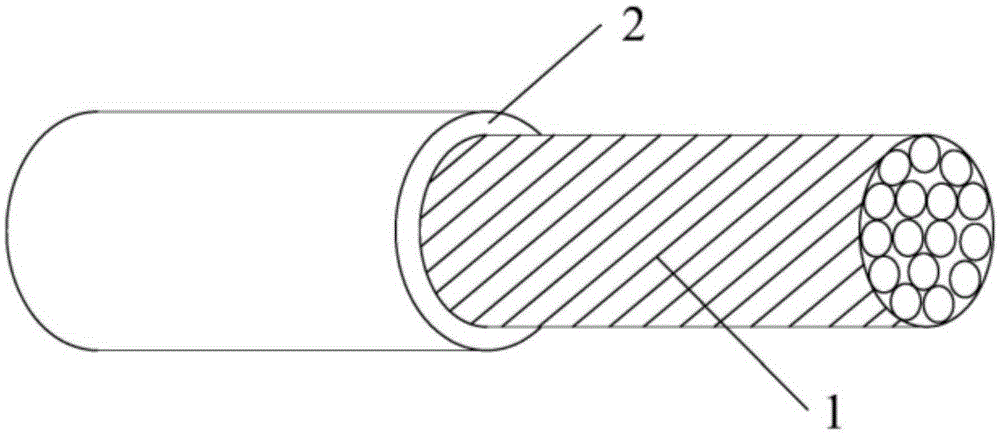

[0014] An automobile electric wire, which includes a stranded conductor and an insulating layer covering the stranded conductor, characterized in that the stranded conductor consists of 156-190 or 612-786 identical conductor monofilament strands The diameter of the conductor monofilament is 0.21mm-0.41mm, and the total cross-sectional area of the stranded conductor is 20mm 2 ~25mm 2 , the material of the insulating layer is precipitation method silicone rubber or vapor phase method silicone rubber, the temperature resistance grades of the precipitation method silicone rubber and gas phase method silicone rubber are both temperature resistant to 200°C, and the thickness of the insulation layer is 0.5mm~ 1.0mm, the density of the insulating layer is 1.2g·cm -3 ~2.0g·cm -3 . The material of the conductor monofilament is bare copper, tin-plated copper, silver-plated copper or nickel-plated copper. The conductor monofilaments are 156, 190, 612 or 786. The diameter of the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com