ESD (electro-static discharge) structure of trench type MOSFET and technological method

A process method and trench-type technology, applied in the field of ESD structure of trench-type MOSFET, can solve problems such as restricting gate PAD area, and achieve the effects of reducing deposition and etching steps, simplifying process steps, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

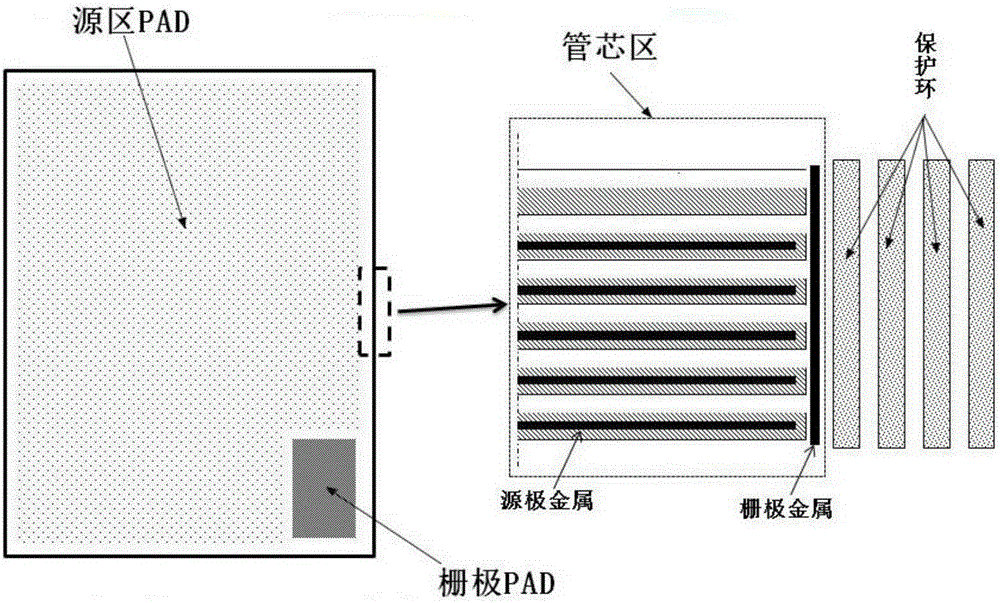

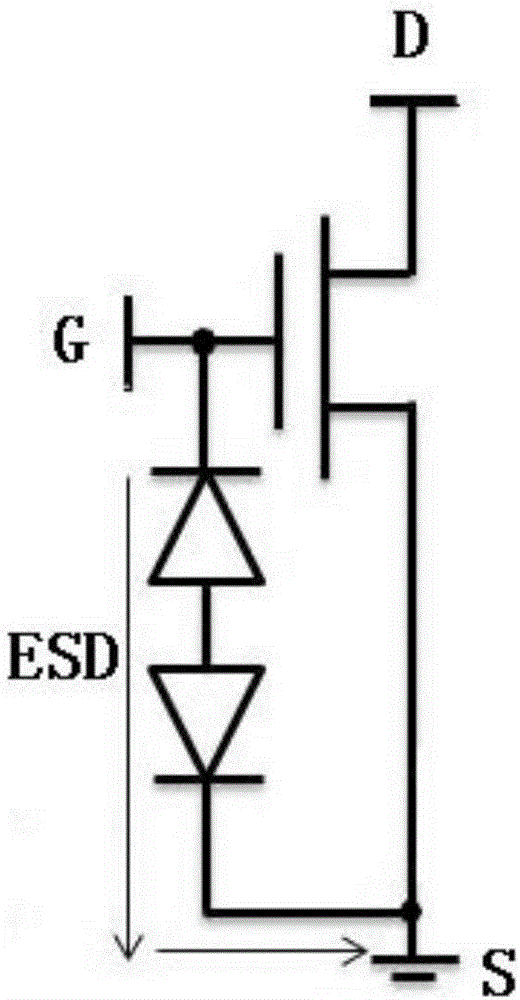

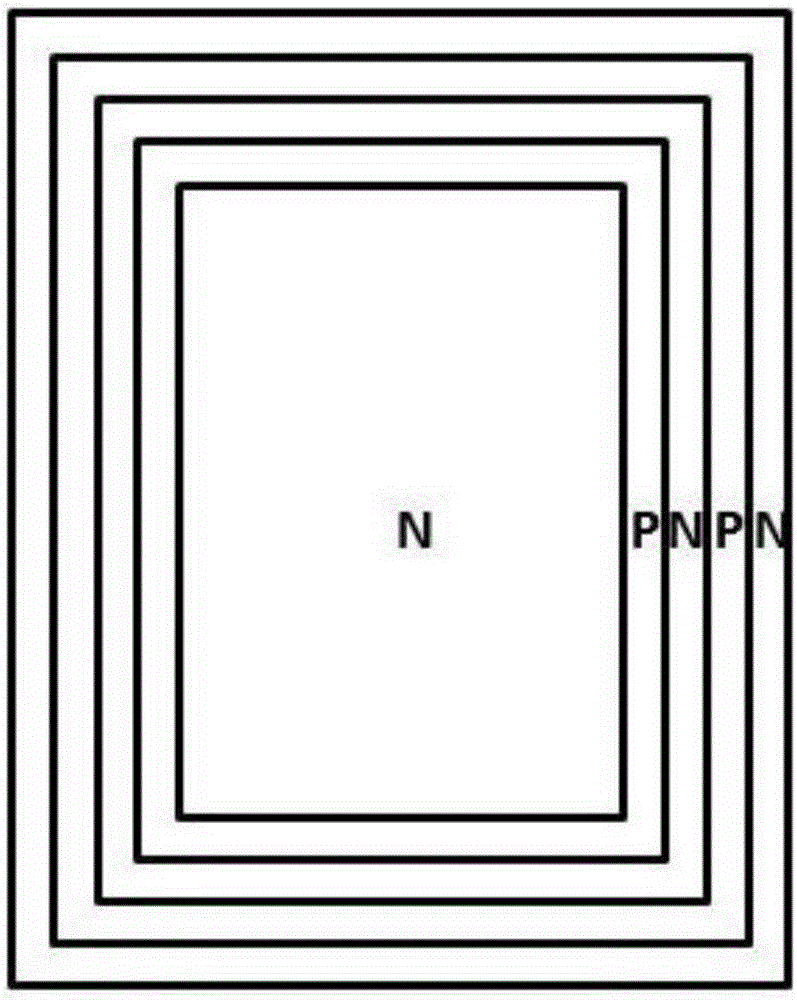

[0036] The ESD structure of trench type MOSFET described in the present invention, as Figure 6 As shown, it includes: there is a guard ring trench around the trench MOSFET, the ESD structure is integrated in the guard ring trench, the guard ring trench passes through the bottom of the body region and is located in the epitaxial layer, and the trench Filled with polysilicon;

[0037] The polysilicon segment is doped with N-P or P-N, or N-P-...-N-P or P-N-...-P-N interval doping to form one or more equivalent series diodes, the structure of which is as follows Figure 7 Shown is a schematic cross-sectional view of the ESD protection ring trench. Electrodes at both ends of the series-connected diodes are respectively connected to the gate and the source of the trench MOSFET. Such as Figure 6 Among them, the trenches of the multi-layer protection ring are led out through the common electrodes 7 and 8, and are connected to the gate and source of the MOSFET by metal to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com