Recovering method of LiFePO4 positive electrode in spent lithium-ion battery

A technology of lithium-ion batteries and recovery methods, which is applied in the field of recovery of LiFePO4 positive electrodes in waste lithium-ion batteries, can solve problems such as the inability to separate Al and Cu, and achieve the effects of easy operation, low cost, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

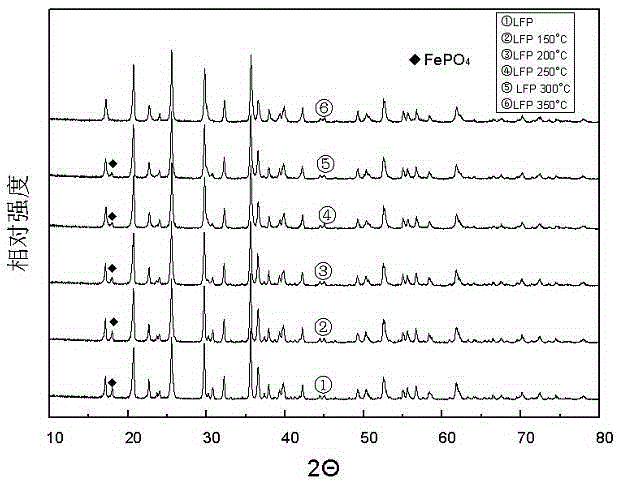

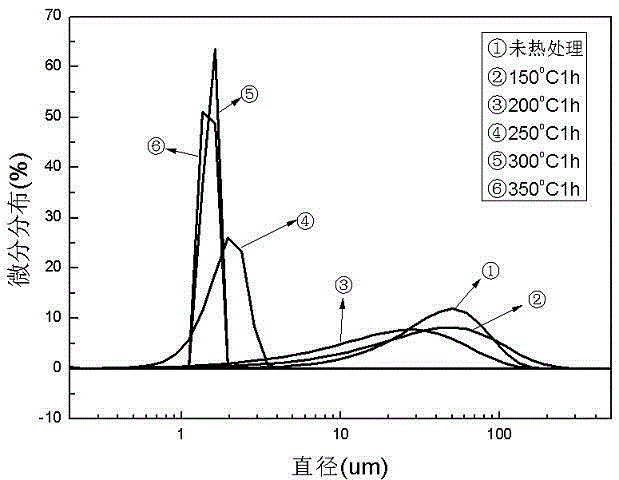

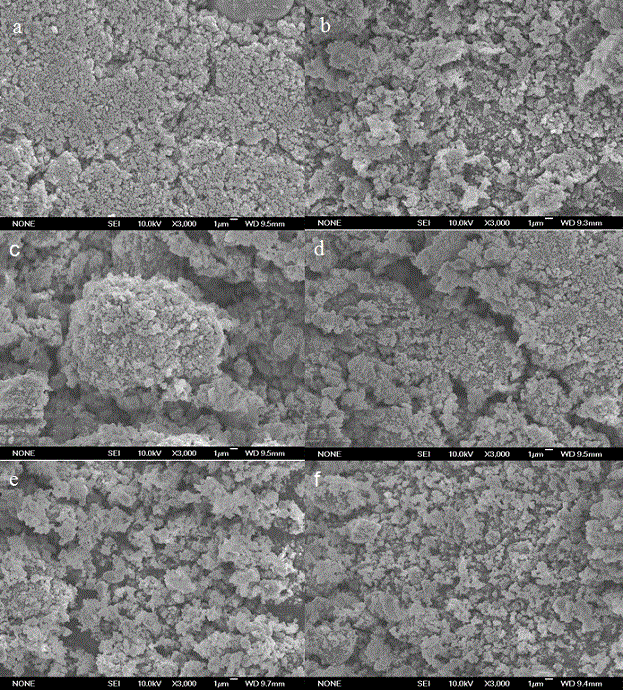

Embodiment 1

[0028] LiFePO in a kind of waste lithium ion battery 4 The recovery method of positive pole comprises the steps:

[0029] S11, 176g of LiFePO 4 Cut the positive electrode material into pieces and pour it into 200ml of DMF solution, the DMF solution is made by mixing DMF and water at a volume ratio of 1:1;

[0030] S12, stirring rapidly to separate the black substance from the aluminum surface, the time is 30min, filter with a vacuum, after a period of time, the black mixture will be left on the filter paper;

[0031] S13, stir the filtrate rapidly again for 30min, then carry out vacuum filtration, repeat the steps of stirring and filtering until the black mixture has no precipitation or little precipitation during the stirring process;

[0032] S14, heat-treating the black mixture obtained by filtration to finally obtain LiFePO 4 and acetylene black mixture material.

[0033] Described heat treatment step comprises the steps:

[0034] S1. Vacuum drying: vacuum-dry the fil...

Embodiment 2

[0040] Except that temperature is 200 ℃ in heat treatment step S3, other is the same as embodiment 1;

Embodiment 3

[0042] Except that temperature is 250 ℃ in heat treatment step S3, other is the same as embodiment 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com